Shield machine with center drilling system

A shield machine and drive system technology, applied in the field of shield machines, can solve problems such as low tunneling resistance and poor cutting effect at the center of the shield machine, and achieve the goal of improving tunneling resistance, reducing tool wear, and enhancing cutting strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

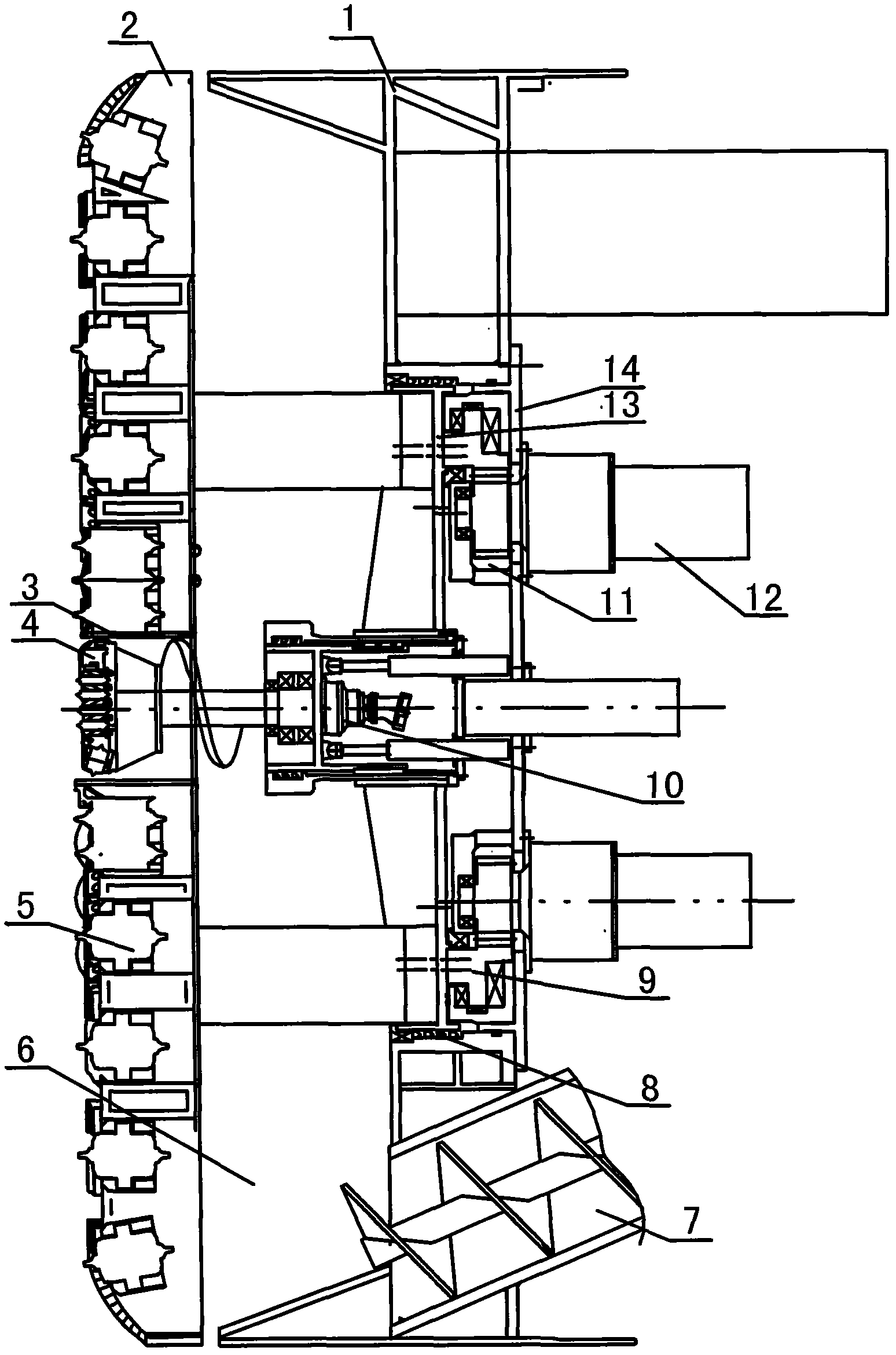

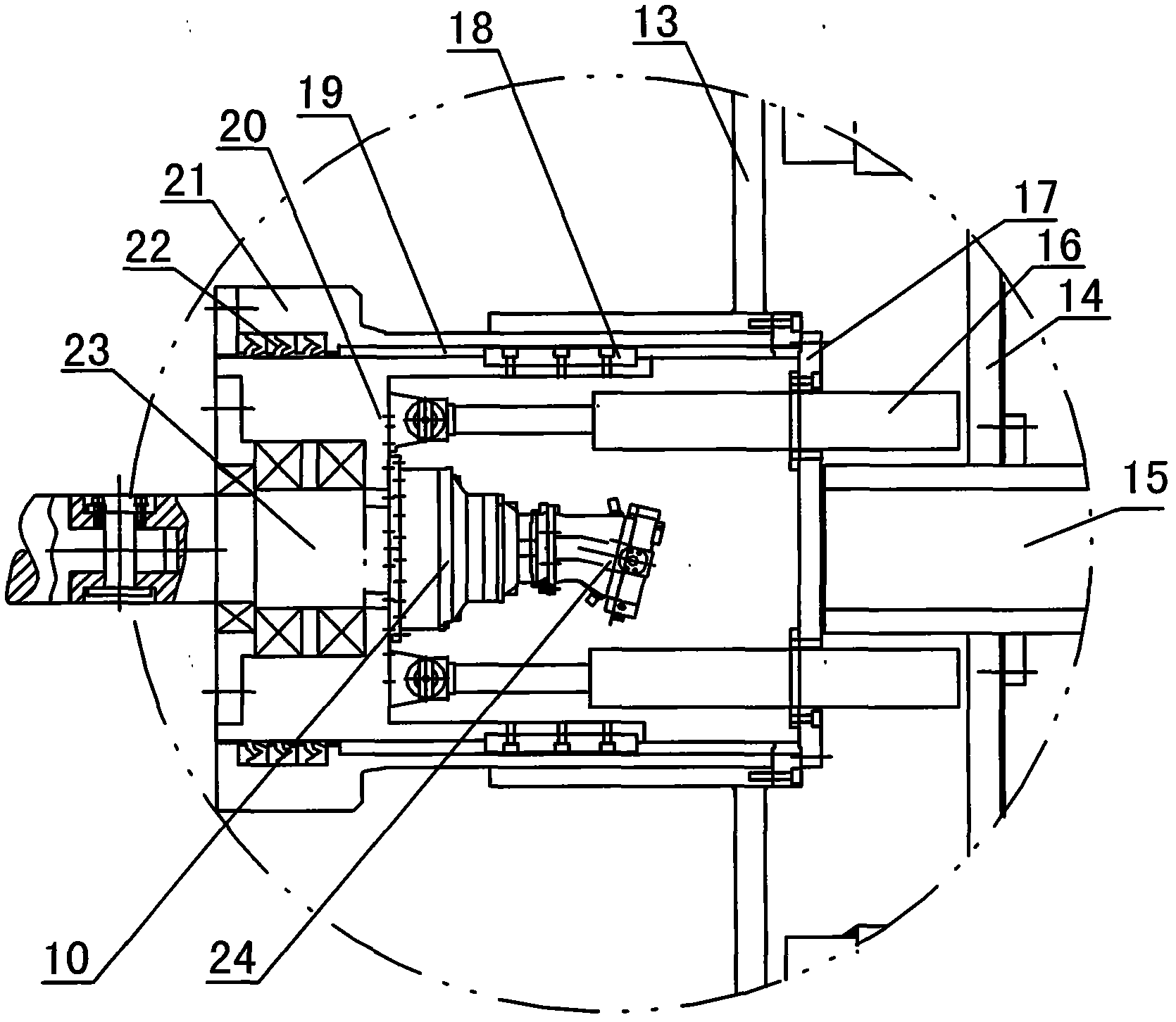

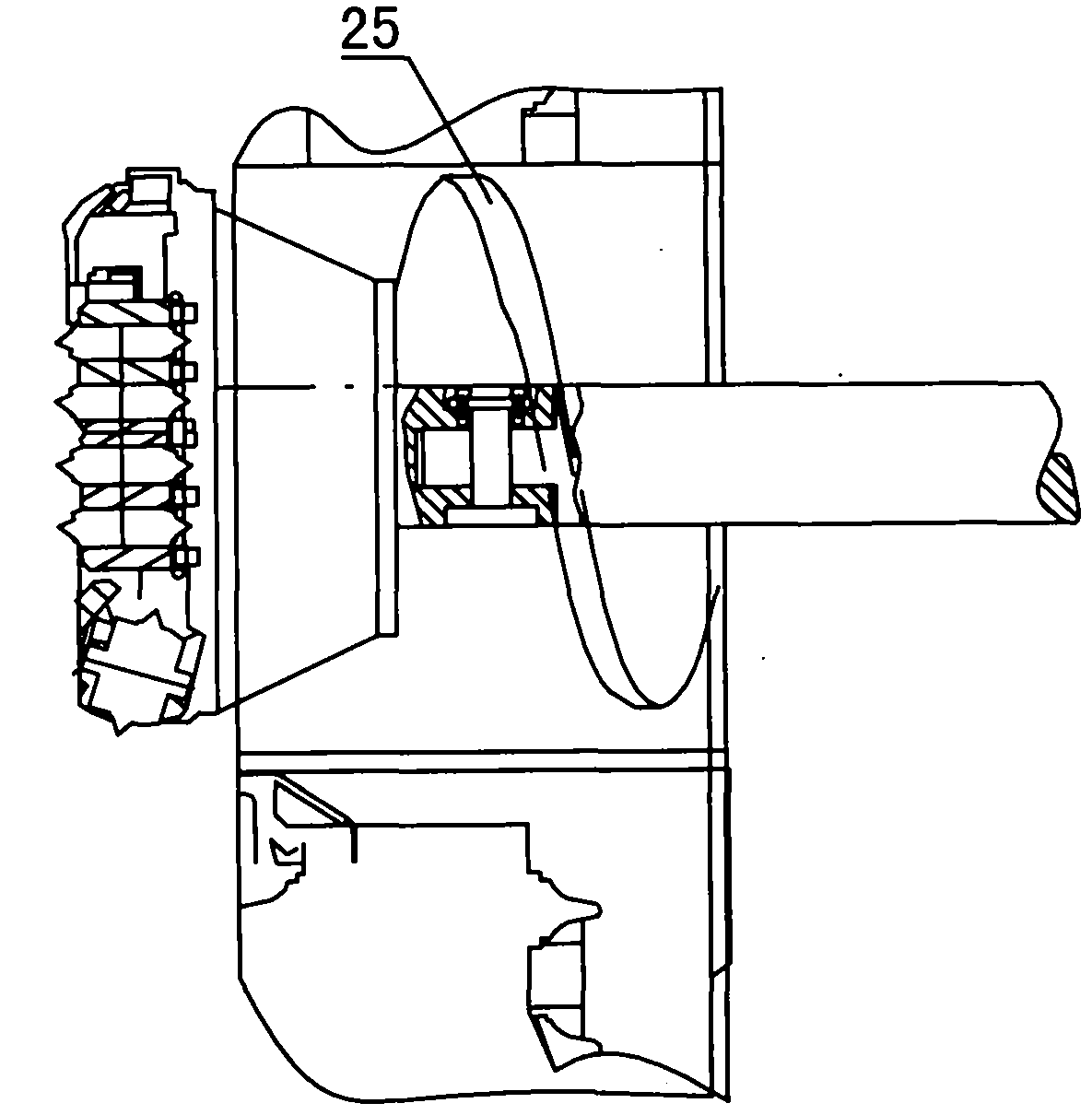

[0017] like Figures 1 to 4 As shown, a specific embodiment of the present invention is given. In the figure, a shield machine with a center drilling system includes a front shield shell 1, a main cutter head 2, a center outlet 3 for cutting rock and soil at the soil bin, a hydraulic pressure Rotary joint 15, the hob 5 on the main cutter head 2, the soil bin 6, the screw conveyor 7 for conveying the cut rock and soil, the sealing system 8 of the shield machine, the reduction box 10, the main drive 12, and the support of the main bearing Disc 14, etc., a small cutter head 4 is installed in the center of the main cutter head 2, and small hobs are installed on it. The number and size of the small hobs can vary according to the soil conditions. The small cutter head 4 is used as the center drilling system. The cutting part is installed on the top of the transmission shaft 23 of the central drilling mechanism, the fixed part of the hydraulic rotary joint 15 is connected with the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com