Multi-purpose high-efficiency pneumatic liquid pump

A high-efficiency technology of air pressure liquid, applied in the direction of liquid variable volume machinery, pump, piston pump, etc., can solve the problems of backflow, low water output efficiency, etc., and achieve the effect of large flow water output and high lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

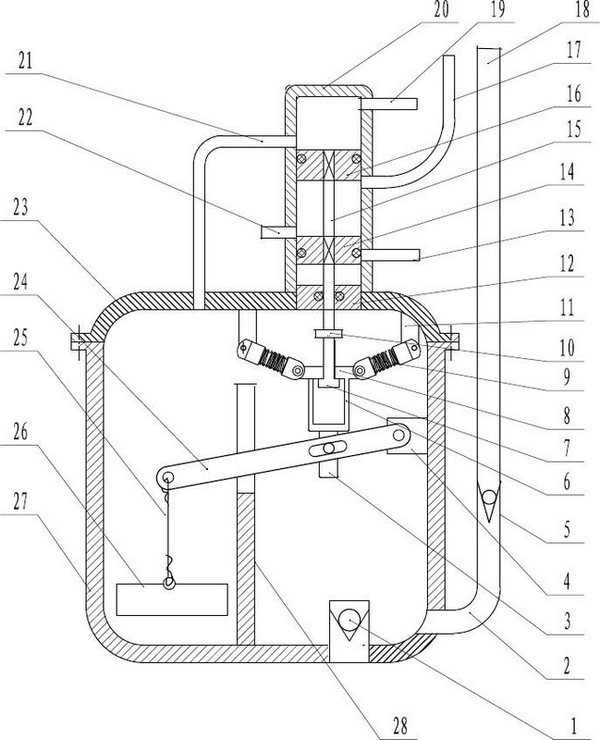

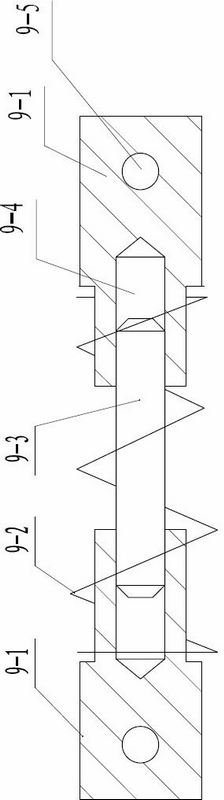

[0025] see figure 1 and figure 2 , which is a small air-driven liquid pump with intermittent water discharge from a single pump. In this embodiment, the lower intake and exhaust pipe 22 and the lower exhaust pipe 13 of the two-position five-way valve are blocked.

[0026] This embodiment includes a main pump, a two-position five-way valve, a float mechanism and a valve stem booster mechanism; the main pump includes a main pump body 27 and a main pump cover 23, and a device is installed There is the water inlet pipe of the main pump water inlet check valve 1, and the main pump outlet connecting pipe 2 equipped with the main pump outlet water check valve 5 is arranged at the lower end of the side wall of the main pump body 27, and the upper end of the main pump outlet connecting pipe 2 Equipped with an outlet pipe 18;

[0027] The two-position five-way valve includes a valve body 20, a lower valve cover 12, a valve stem 15 equipped with an upper piston 16 and a lower piston ...

Embodiment 2

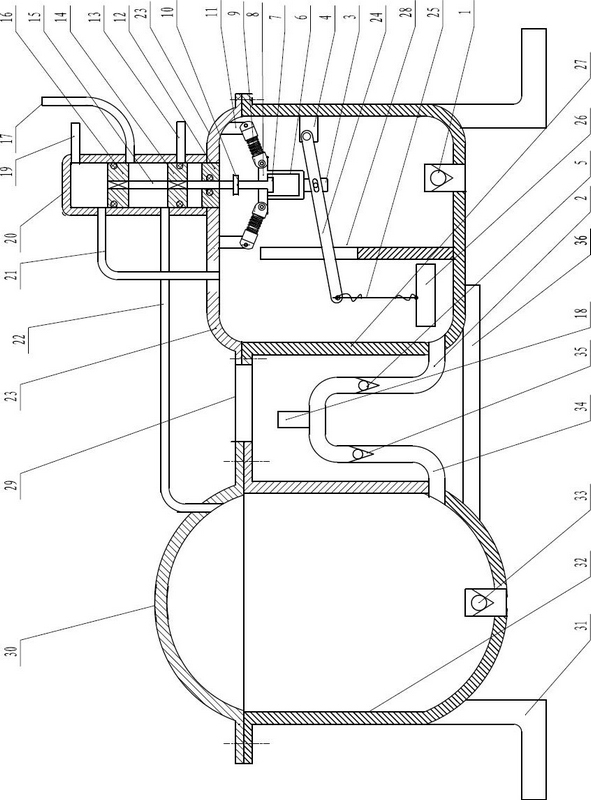

[0034] See attached image 3, which connect the left and right sides of the main and auxiliary pumps, and complete continuous water pumping. The difference between this embodiment and Embodiment 1 is that it also includes an auxiliary pump. The auxiliary pump includes an auxiliary pump body 32 and an auxiliary pump cover 30. On the bottom of the auxiliary pump body 32, there is a water stop for the auxiliary pump. The water inlet pipe of the return valve 33 is provided with an auxiliary pump outlet connecting pipe 34 equipped with an auxiliary pump outlet check valve 35 at the lower end of the side wall of the auxiliary pump body 32. The auxiliary pump outlet connecting pipe 34 and the main pump outlet connecting pipe 2 Connect with the outlet pipe 18 through a tee;

[0035] The lower intake and exhaust port of the two-position five-way valve communicates with the cavity of the auxiliary pump through the lower intake and exhaust pipe 22, and the lower exhaust pipe 13 is insta...

Embodiment 3

[0041] See attached Figure 4 , the main and auxiliary pumps are connected in parallel up and down, which is suitable for deep wells and continuous water pumping.

[0042] The difference between embodiment 3 and embodiment 2 is that the auxiliary pump is connected up and down with the main pump through the connecting plate 37 , and the working process of embodiment 3 is the same as that of embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com