A filter pressure reducing valve

A filter pressure reducing valve and air filtration technology, which is applied in the field of filter pressure reducing valves, can solve the problems of pressure reducing valves that cannot be returned to zero, high processing costs, and complex diaphragm seat structures, so as to improve pressure regulation accuracy and reduce production The effect that the cost and processing accuracy are easy to guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

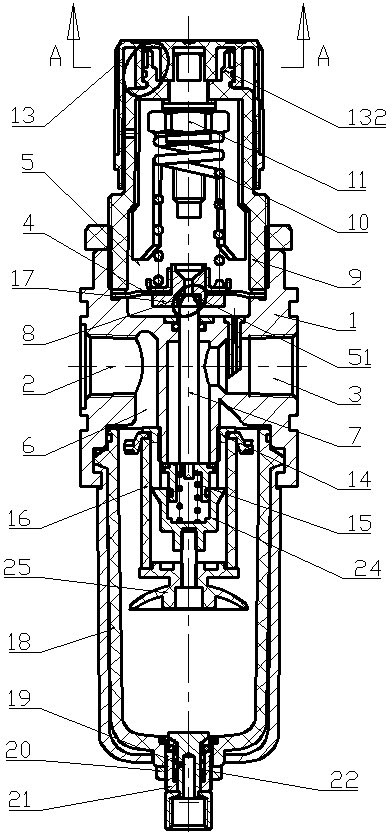

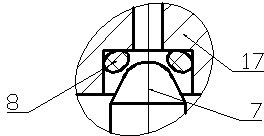

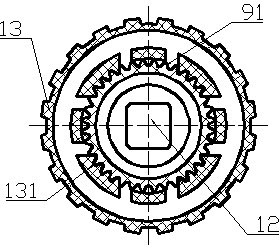

[0030] figure 1 It is a filter pressure reducing valve of the present invention, which includes a valve body 1, and the left and right sides of the valve body 1 are respectively provided with a high-pressure inlet 2 and a low-pressure outlet 3; it also includes a pressure regulating assembly connected to the upper side of the valve body 1 And the air filter assembly connected to the lower part of the valve body 1 , the valve body 1 and the pressure regulating assembly are separated into an upper diaphragm chamber 5 and a lower valve core chamber 6 through a diaphragm assembly. The spool chamber 6 is provided with a spool 7 capable of moving up and down, the bottom end of the spool 7 is fixedly connected with the spool seat 14, and the connection seat 24 between the spool seat 14 and the valve body is fixed. A balance spring 15 is provided between them. It is used to block the communication between the high-pressure inlet 2 and the low-pressure outlet 3 when the pressure reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com