Heat sink and led lamp with heat sink

A technology of heat dissipation device and heat dissipation substrate, which is applied to cooling/heating devices of lighting devices, lighting devices, lighting and heating equipment, etc., which can solve the problems of poor heat dissipation effect, chaotic wind direction, and inability to effectively dissipate heat, and achieve good heat dissipation effect, Improved cooling effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

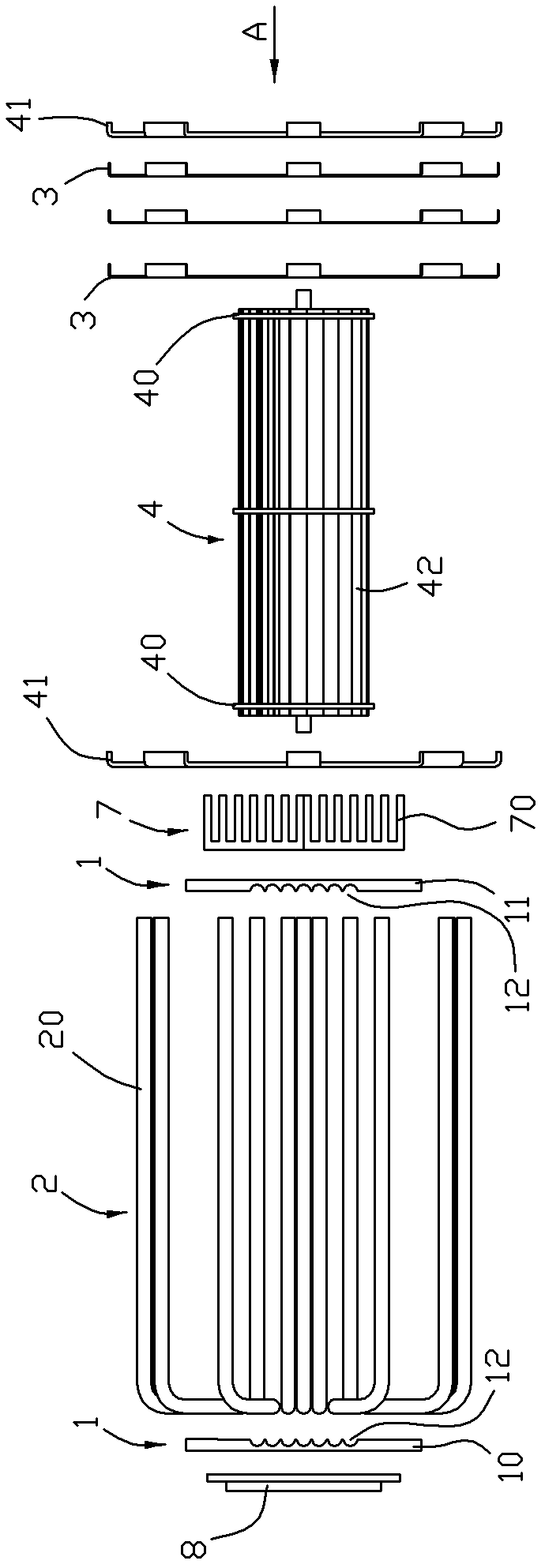

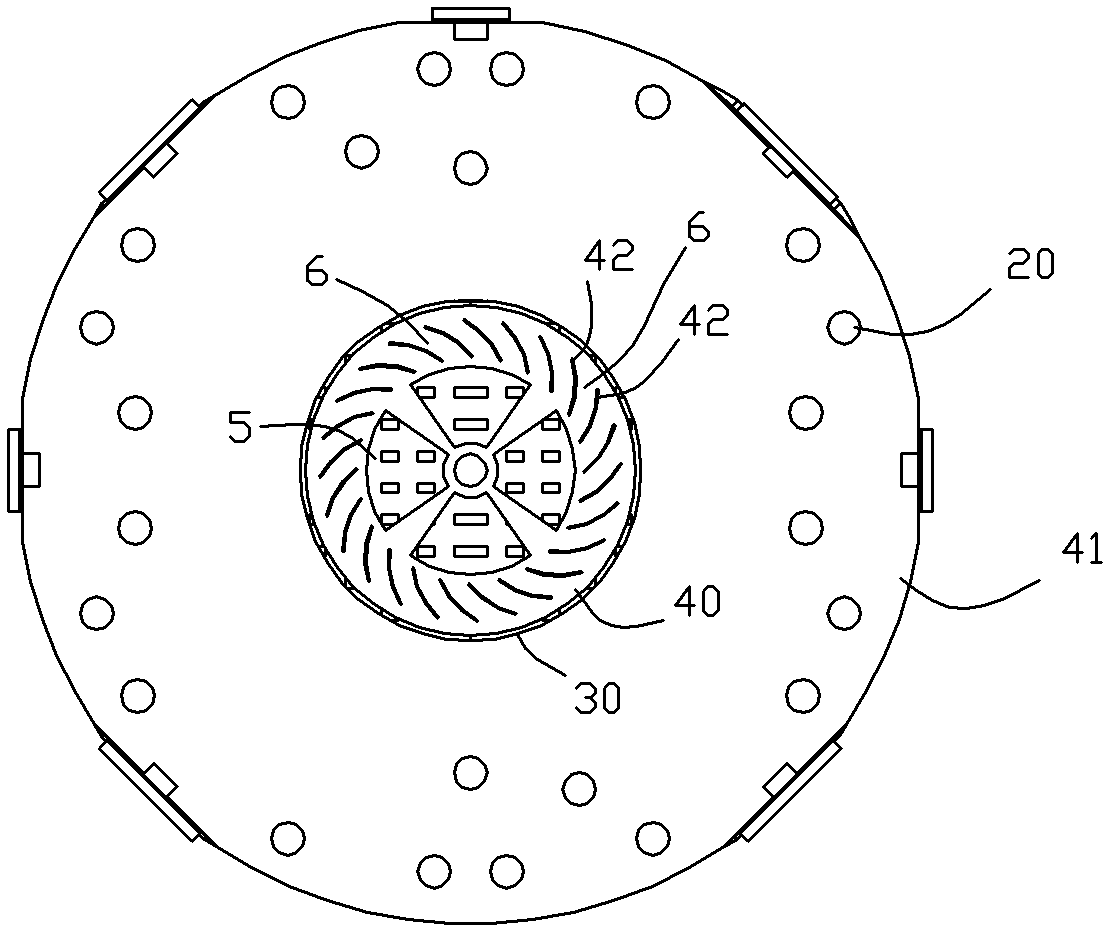

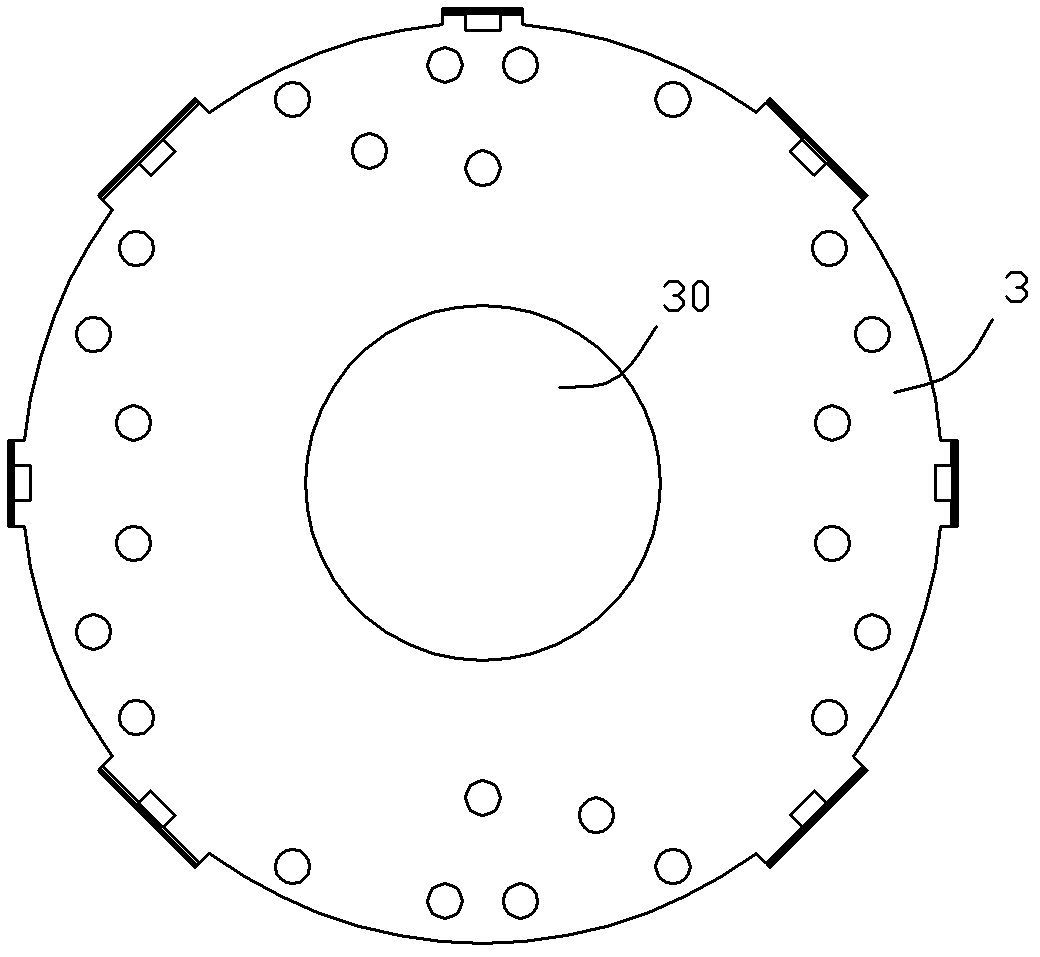

[0026] see Figure 1 to Figure 4 , shows a preferred embodiment of a heat dissipation device of the present invention, including a heat dissipation substrate 1, several heat pipes 2, a row of several heat dissipation fins 3 arranged at intervals ( figure 1 Three cooling fins are schematically drawn in , in actual use, the number of specific cooling fins used can be selected in combination with the length of the heat pipe and the drum fan) and the fan 4, leaving space between the cooling fins Reasonable spacing is used to ensure the smooth flow of heat dissipation. The center of each heat dissipation fin has a central hole 30, so that the center position between the several heat dissipation fins forms a cylindrical accommodation space. The fan is a drum type Fan, the drum-type fan is arranged in the cylindrical accommodation space, each of the heat pipes is partially embedded in the heat dissipation substrate, and the protruding end of each heat pipe has an extension section 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com