A high temperature tensile fixture

A high-temperature, fixture technology, applied in the field of tensile fixtures, to achieve the effect of increasing friction, large coverage of clamping range, and large clamping range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

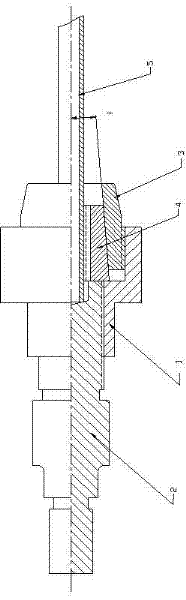

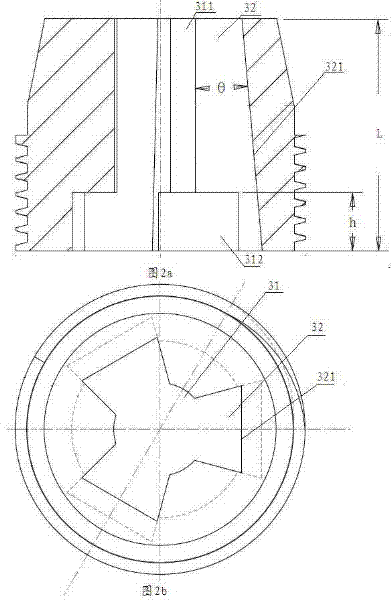

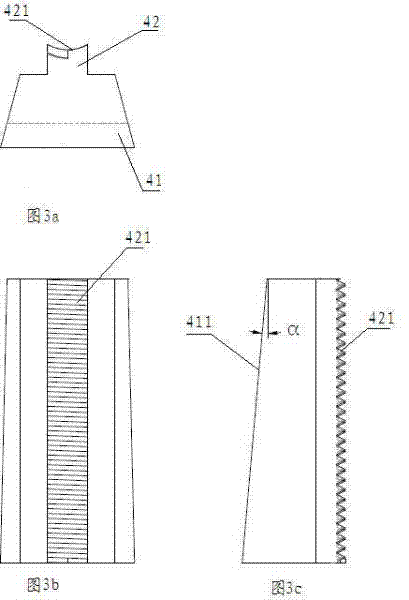

[0033] like figure 1 Combine figure 2 As well as image 3 and Figure 5 The present invention fixture includes top rods 2, jacket cylinder 1. Inner sleeve 3, clamping tile 4, the outer sleeve 1 has a step -shaped connection hole 11, and the ends of the connection hole 11 have a thread structure;The top rod 2 has a thread structure 22 that is matched with the jacket cylinder, and is installed on the end of the small pore diameter of the coat 1 connecting hole;1 Connect the ends of the large pore diameter, which has an inner sleeve 3 inner installation holes 31. The edge of the installation hole 31 has a set of guidance grooves 32.The θ is greater than 0 °, that is, the guidance slot has a certain tilt; the holding tile 4 is installed in the guidance slot 32, and the number of clamping tile 4 is the same as the number 32 of the guide slot 32.Installation department 41 and clamping department 42, the installation department 41 is equipped with the installation with the guide slot 32, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com