Low resistance Li-ion battery cap

A lithium-ion battery and low-resistance technology, which is applied to battery pack components, circuits, electrical components, etc., can solve the problem that the cap structure is difficult to realize, and achieve the effects of simple structure, low internal resistance, and high safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

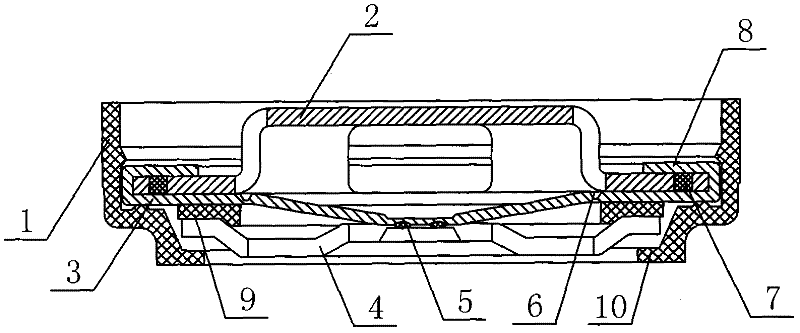

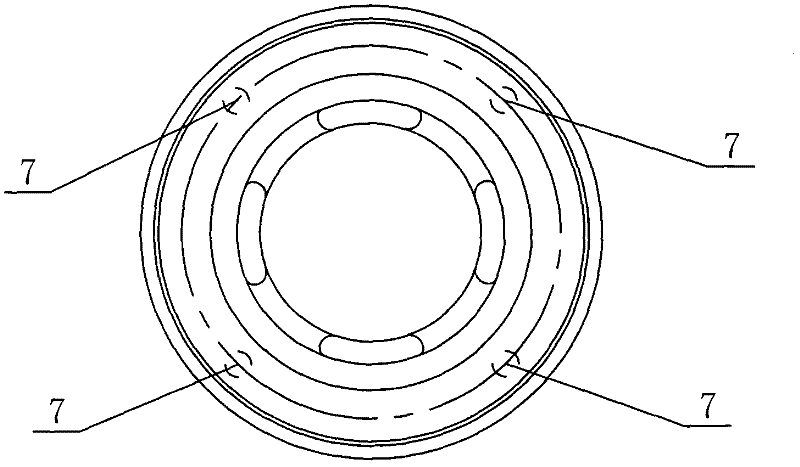

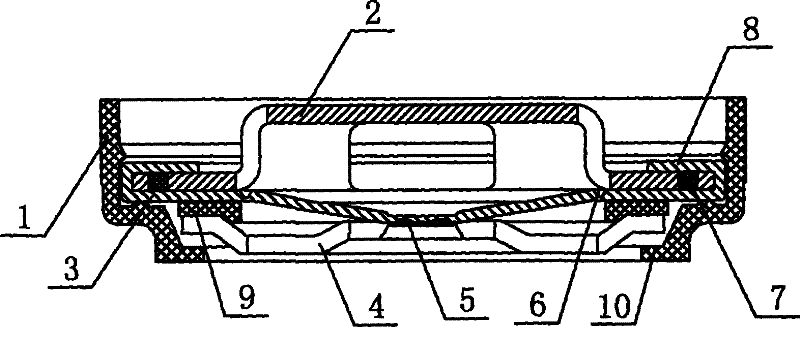

[0015] Please refer to figure 1 and figure 2 as shown, figure 1 It is a sectional view of the low-resistance lithium-ion battery cap of the present invention; figure 2 It is a top view of the low-resistance lithium-ion battery cap of the present invention.

[0016] In this embodiment, the low-resistance lithium-ion battery cap includes a sealing ring 1, and the sealing ring 1 is respectively packaged with a top cover 2, an explosion-proof sheet 3 and a hole plate 4 from top to bottom. The explosion-proof discs 3 are connected by four laser welding spots 7, which are evenly distributed on the bonding surface formed between the top cover 2 and the explosion-proof disc 3, and the laser welding spots 7 are distributed on the same Above the circumference, the orifice plate 4 is arranged on the bottom of the explosion-proof disk 3 through the connection welding spot 5, and an insulating sheath 9 is arranged between the explosion-proof disk 3 and the orifice plate 4, and the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com