Method for producing fragrance-containing particle composition

A manufacturing method and composition technology, which is applied in the field of particle composition manufacturing, can solve the problems of easy oxidation and deterioration of spices, poor preservation, incomplete coating, etc., and achieve good preservation stability, high fluidity, and high fragrance persistence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031]In the preparation of powder flavors, for example, it can be obtained as follows, that is, using fatty acid monoglycerides, fatty acid diglycerides, fatty acid triglycerides, propylene glycol fatty acid esters, sucrose fatty acid esters, polyglycerol fatty acid esters, lecithin, modified Starch, sorbitan fatty acid esters, soap bark extract, acacia gum, tragacanth gum, guar gum, karaya gum, xanthan gum, pectin, alginic acid and its salts, carrageen Surfactants such as polysaccharides, gelatin, casein, dextrin, monosaccharides, disaccharides, polyalcohols and other suitable excipients emulsify these oily material mixtures, and use spray drying, vacuum drying, freeze drying, etc. The drying method is to dry, thus obtainable. A major feature of the present invention is that the once-powdered fragrance is used as a raw material for encapsulation in a hydrocarbon matrix by the above method.

[0032] The amount of the fragrance used in the present invention is not particularl...

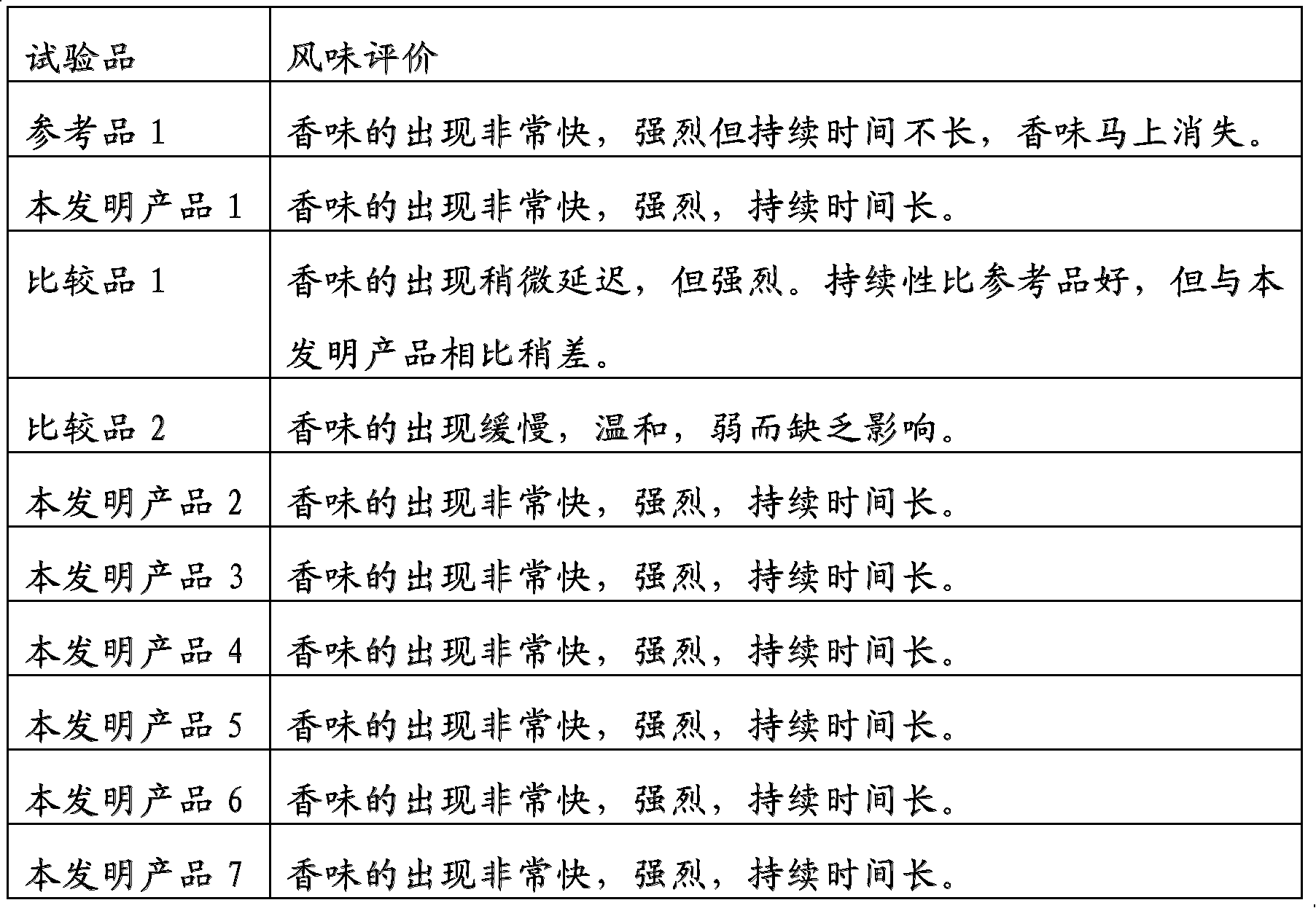

Embodiment

[0050] Examples are given below to describe the present invention in more detail.

reference example 1

[0051] Reference example 1 (preparation of lemon powder flavor)

[0052] After dissolving 300 g of modified starch and 400 g of dextrin in 1300 g of soft water, add 300 g of lemon oil and emulsify with a homomixer to make the emulsified particle size about 0.5 μm to 2 μm to obtain an O / W emulsion. Using a mobile small-sized spray dryer (manufactured by Niro Japan), the emulsion was spray-dried at a hot air inlet temperature of 150° C., an exhaust air temperature of 80° C., and a sprayer rotation speed of 20,000 rpm to obtain 980 g of powdered fragrance containing 30% lemon oil (reference Product 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com