Apparatus and method for coating a substrate with CVD

A technology for coating substrates and heating conductors, applied in coatings, metal material coating processes, gaseous chemical plating, etc., to achieve the effects of long life, durable devices, and increased life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

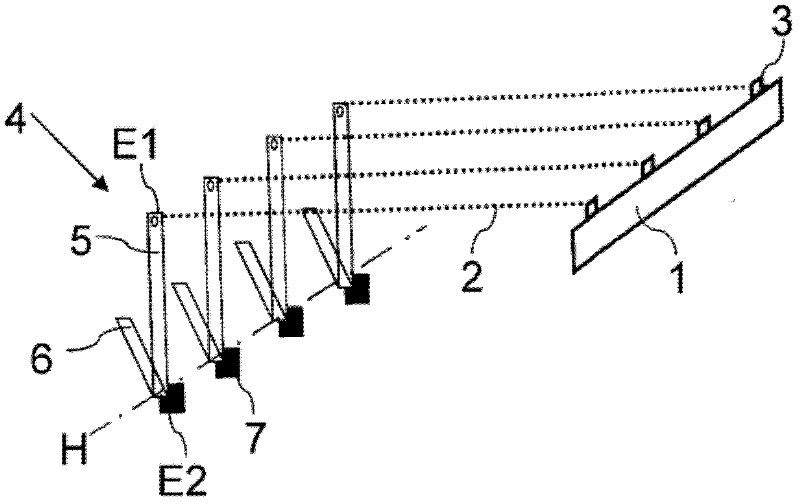

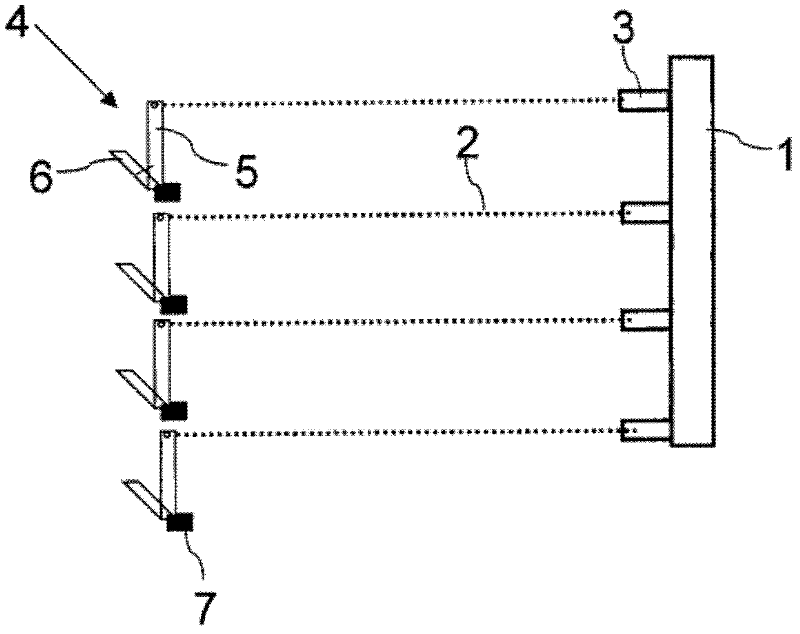

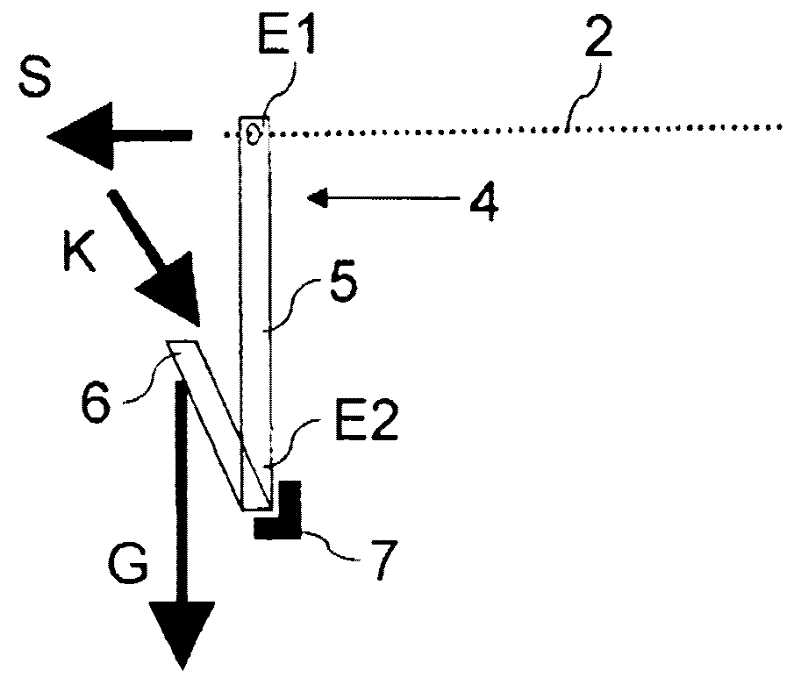

[0036] figure 1 A schematic diagram of the first device is shown. A plurality of heating conductors 2 are mounted consecutively in the row direction on the first electrode 1 , preferably at approximately the same distance from one another. The heating conductor 2 is held by being clamped in a holding element 3 arranged on the first electrode 1 . The heating conductors 2 are each held taut by means of tensile elements 4 arranged at their ends. Each tensile element 4 has a swivel arm 5 which is rotatable about a horizontal axis H. As shown in FIG. One end of the heating conductor 2 is mounted on the first end E1 of the respective tensile element 4 . The lever arm 6 extends from the second end E2 in a direction away from the first electrode 1 . The swivel arm 5 and the lever arm 6 , which is firmly connected to the swivel arm 5 , for example by welding, form a sharp angle preferably in the range of 20 to 60°. The gravity of the lever arm 6 exerts a tilting moment on the rota...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap