Preparation method of fishbone calcium milk tablets

A technology of fish bone calcium and milk flakes, which is applied in the directions of milk preparations, dairy products, applications, etc., can solve the problem of high cost, and achieve the effects of convenient consumption, expanded utilization, and no fishy smell.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

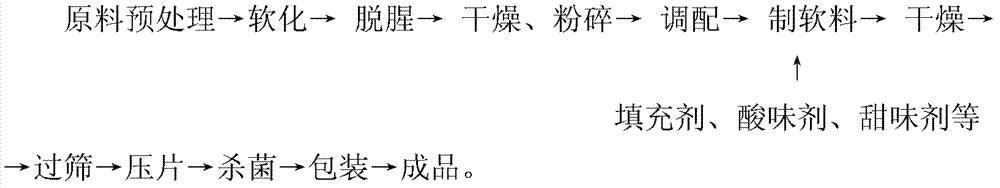

Image

Examples

Embodiment 1

[0046] Embodiment 1 A kind of preparation method of fishbone calcium milk tablet, comprises the steps:

[0047] (1) Raw material pretreatment: cleaning the gillless fish skulls and fish vertebrae left after the freshwater fish are harvested;

[0048] (2) softening: put the cleaned fish bones into a pressure vessel, and pressurize them at 0.10 MPa for 55 minutes; wash the fish bones with water;

[0049] (3) Deodorization: the softened fish bones are cooled to room temperature, and the cooled fish bones are soaked in 35°C and 2% yeast aqueous solution at a mass ratio of 1:2 for 60 minutes, and washed with water. clean fish bones;

[0050] (4) Drying and crushing: the fish bones after deodorization are placed in a drying oven at 100°C, dried by air for 50 minutes, then crushed, and passed through an 80-mesh sieve to obtain fish bone meal;

[0051] (5) Deployment: Mix fishbone powder, milk powder, aspartame, citric acid and β-cyclodextrin through a 80-mesh sieve to form a mixtur...

Embodiment 2

[0055] Embodiment 2 A kind of preparation method of fishbone calcium milk tablet comprises the following steps:

[0056] (1) Raw material pretreatment: clean the gillless fish skulls left after freshwater fish are harvested;

[0057] (2) softening: put the cleaned fish bones into a pressure vessel, pressurize at 0.09MPa for 60 minutes; wash the fish bones with water;

[0058] (3) Deodorization: cool the softened fish bones to room temperature, soak the cooled fish bones in 35°C and 3% yeast aqueous solution at a mass ratio of 1:3 for 40 minutes, and wash with water clean fish bones;

[0059] (4) Drying and crushing: the fish bones after deodorization are placed in a 90°C drying oven, air-dried for 55 minutes, then crushed, and passed through an 80-mesh sieve to obtain fish bone meal;

[0060] (5) Deployment: Mix fishbone powder, milk powder, aspartame, citric acid and β-cyclodextrin passing through an 80-mesh sieve to form a mixture in a mass ratio of 45:35:0.8:4.0:0.2;

[...

Embodiment 3

[0064] Embodiment 3 A kind of preparation method of fishbone calcium milk tablet, comprises the steps:

[0065] (1) Raw material pretreatment: clean the remaining fish backbone after the freshwater fish is harvested;

[0066] (2) softening: put the cleaned fish bones into a pressure vessel, pressurize at 0.11MPa for 50 minutes; wash the fish bones with water;

[0067] (3) Deodorization: cool the softened fish bones to room temperature, soak the cooled fish bones in 35°C and 2% yeast aqueous solution at a mass ratio of 1:3 for 50 minutes, and wash with water clean fish bones;

[0068] (4) Drying and pulverization: the fish bones after deodorization are placed in a drying oven at 110° C., air-dried for 45 minutes, then pulverized, and passed through an 80-mesh sieve to obtain fish bone meal;

[0069](5) Deployment: Mix fishbone powder, milk powder, aspartame, citric acid and β-cyclodextrin passing through an 80-mesh sieve to form a mixture in a mass ratio of 50:40:0.8:4.0:0.2;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com