A kind of miniaturization soybean milk machine and the method for making soybean milk

A soymilk maker and soymilk technology, which is applied in the field of food processing, can solve the problems of occupying space for consumers, large packaging capacity, and bulky soymilk maker, and achieve the effects of miniaturization, saving raw materials and transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

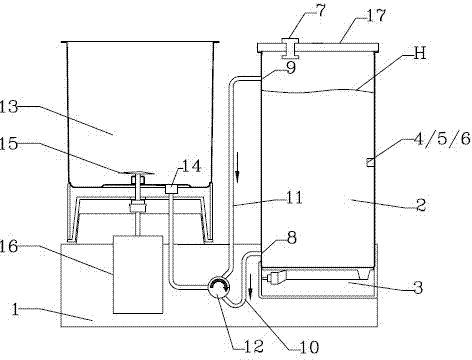

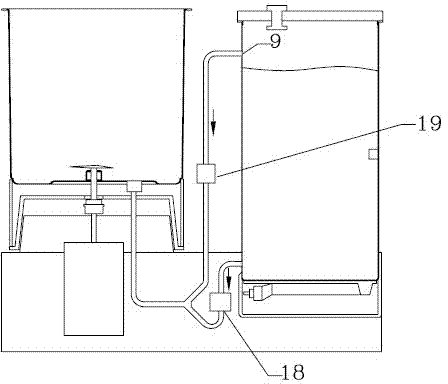

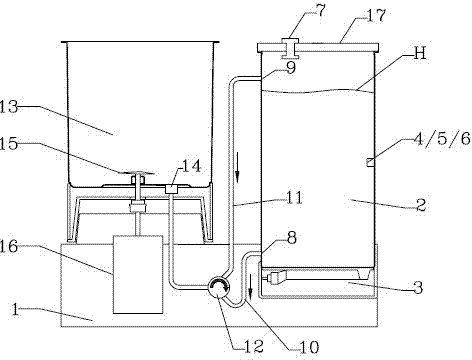

[0021] The soymilk maker and the soymilk making method of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0022] as attached figure 1 As shown, the soya-bean milk machine comprises a machine base 1, and one side of the machine base 1 is provided with a water tank 2, and the other side is provided with a cooking cup 13, and the bottom of the water tank 2 is provided with a heating plate 3 (wherein the water tank 2 and the heating plate 3 The structure can be replaced by a boiler, and then a water source can be connected externally to the boiler), and the water level detector 4 and a temperature sensor 5 or a pressure sensor 6 are arranged on the inner wall of the water tank 2, and these parts are all connected with the control device of the soybean milk machine (belonging to The passing parts of the soybean milk machine (not shown in the figure) are connected and provide detection signals to the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com