High chromium crushing wall and assembly for cone sand making machine

A crushing wall and sand making machine technology, applied in the direction of grain processing, etc., can solve the problems that the crushing wall and the crushing wall assembly cannot be manufactured, there is no way to slow the release of the crushing wall, and the service life is short, so as to solve the problem of being vulnerable to impact Effects of breakage, reduced usage cost, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

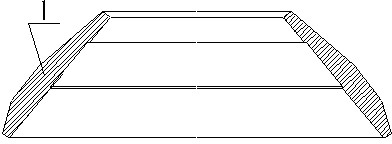

[0012] Embodiment 1: with reference to attached figure 1 . A special high-chromium crushing wall for a conical sand making machine, which includes a crushing wall assembly. The material of the crushing wall 1 is high-chromium white wear-resistant cast iron, and its chromium content is equal to or greater than 9% and equal to or less than 32%. That is, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 30, and including two integers between decimal points.

Embodiment 2

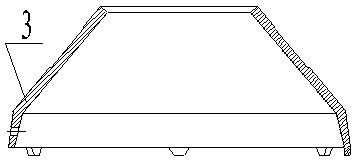

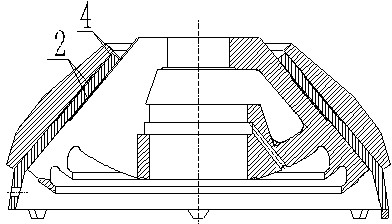

[0013] Embodiment 2: with reference to attached Figure 1-2 . A special high chromium crushing wall assembly for a conical sand making machine, which includes a crushing wall and a crushing wall backing plate, and the gap filling layer between the high chromium white wear-resistant cast iron crushing wall 1 and the crushing wall backing plate 3 is Zinc alloy layer 2. A plurality of watering grooves 4 for pouring zinc alloy are formed on the matching surface of the broken wall 1 and the backing plate 3 of the broken wall. The broken wall backing plate 3 is made of high manganese steel. A plurality of pouring grooves 4 for pouring zinc alloy are formed on the matching surface of the crushing wall backing plate 3 and the high chromium white cast iron crushing wall 1 .

Embodiment 3

[0014] Embodiment 3: On the basis of Embodiments 1 and 2, the gap filling layer between the broken wall backing plate 3 and the moving cone 5 is a zinc alloy layer 2 . A plurality of watering grooves 4 for watering zinc alloy are formed on the matching surface of the broken wall backing plate 3 and the moving cone 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com