Coal mill startup control method, system and coal mill startup equipment

A technology for starting equipment and coal mills, which is applied to the starters of single multi-phase induction motors, motor generators/starters, grain processing, etc., and can solve the problems of abnormal operation of motor equipment, impact of power grid and motor equipment, and impact on power grid Equipment life and other issues to achieve the effect of protecting safe operation, preventing failures, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

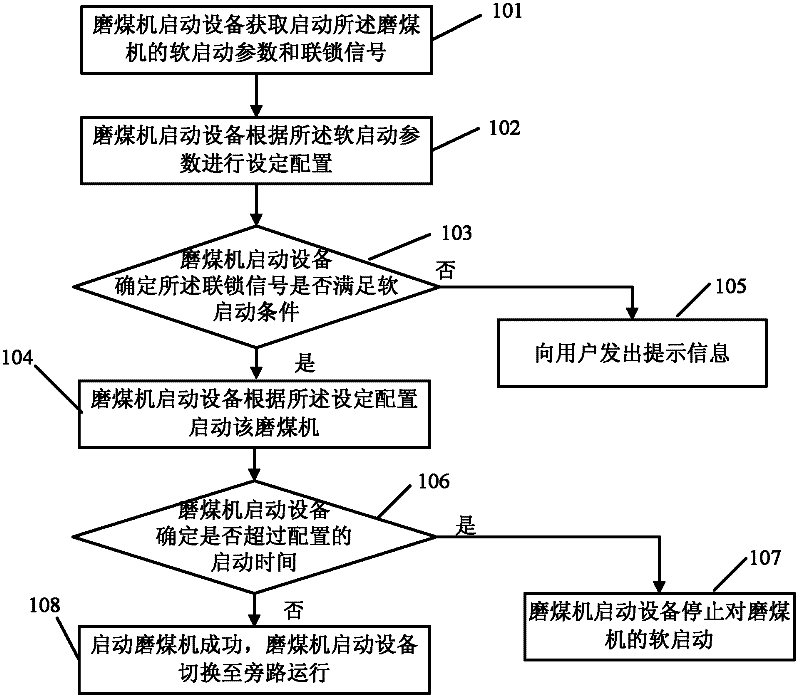

[0040] This embodiment provides a starting control method of a coal mill, such as figure 1 As shown, the method includes:

[0041] Step 101, before starting the coal mill, the coal mill starting equipment obtains the soft start parameters and interlocking signals for starting the coal mill;

[0042] Further, the acquisition of soft start parameters for starting the coal mill can be achieved in the following manner:

[0043] 1. The starting equipment of the coal mill receives the soft start parameters input by the user through the human-computer interaction interface;

[0044] Second, if the user does not input the soft start parameters, the coal mill starting equipment can use the default soft start parameters set at the factory as the obtained soft start parameters.

[0045] Further, the above-mentioned acquisition of the interlocking signal mainly refers to receiving the interlocking signal from the coal mill to be started, and if there is a connected remote control termin...

Embodiment 2

[0075] In order to facilitate the implementation of the method in the first embodiment above. This embodiment provides a coal mill starting device 50, such as Figure 5 As shown, the device includes: an interaction module 51 , a signal acquisition module 52 , a control module 53 and a soft start module 54 .

[0076] Among them, the interaction module 51 is used to obtain the soft start parameters for starting the coal mill; the signal acquisition module 52 is used to obtain the interlock signal for starting the coal mill; the control module 53 is used to obtain the parameters according to the interaction module 51. The soft-start parameters obtained are configured, and it is determined whether the interlock signal obtained by the signal acquisition module 52 meets the soft-start condition; the soft-start module 54 is used for when the control module 53 determines that the soft-start condition is met, according to the set The configuration of the control module 53 starts the m...

Embodiment 3

[0099] This embodiment provides a starting control system of a coal mill, the system includes a coal mill and a coal mill starting device, the specific embodiment of the coal mill starting device can be as described in the second embodiment above.

[0100] In addition, the system may also include: a remote control terminal connected with the coal mill starting equipment. The remote control terminal can remotely control the starting of the coal mill by controlling the starting equipment of the coal mill.

[0101] The coal mill starting system provided in this embodiment can not only reduce the impact on the power grid and the motor of the coal mill when starting the coal mill through soft start, protect the normal operation of the power grid and the motor, but also can The start-up of the coal mill is controlled by means of remote control, which is convenient for remote operation and has high usability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com