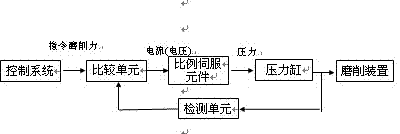

A Belt Grinding Device with Programmable Grinding Force Control

A technology of abrasive belt grinding and grinding force, which is applied in the direction of abrasive belt grinders, grinding/polishing equipment, grinding machines, etc., to achieve a smooth transition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

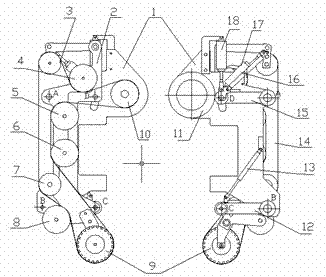

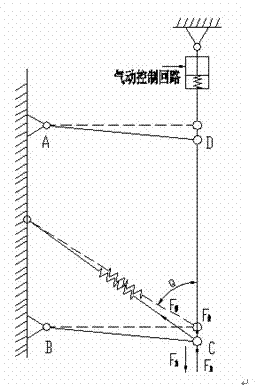

[0024] The abrasive belt grinding device of the present invention comprises a driving motor 11, a base plate 1, a moving plate 2, a grinding wheel train and an abrasive belt 14, a grinding force control device, a pressure cylinder 18, a compensating spring 13 and an abrasive belt tensioning mechanism; The grinding wheel system includes a driving wheel 10, a tensioning wheel 3, a contact wheel 9 and several guide wheels; the driving motor 11 and the driving wheel 10 are fixed on the base plate 1, and the contact wheel 9 and the tensioning wheel 3 are fixed on the moving plate 2; The plate 2 and the base plate 1 are connected through the hinge of a parallel four-bar linkage mechanism composed of equal-length upper and lower links; the pressure cylinder 18 is fixed above the base plate 1 of the grinding device, and a section of the compensation spring 13 is fixedly connected to the base plate 1. One section is fixedly connected to the moving plate 2; the grinding force control dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com