Identifiable environmentally-friendly scale and corrosion inhibitor

An environment-friendly, scale and corrosion inhibitor technology, applied in scale removal and water softening, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the difficulty of chemical concentration and poor scale and corrosion inhibition performance , Natural and biological ecological disasters and other problems, to achieve the effect of inhibiting the growth of bacteria and algae, reducing biological corrosion, and reducing erosion and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

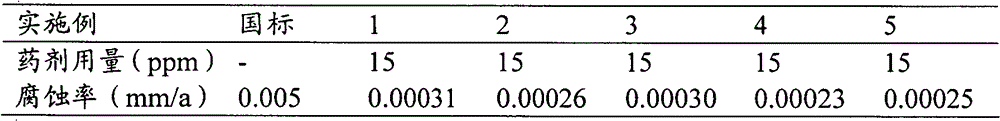

Embodiment 1

[0034] 1. Preparation of polymers containing fluorescent groups

[0035] Take the following amount of raw materials:

[0036] Maleic anhydride 29%;

[0037] Acrylic 15%;

[0038] Acrylonitrile 2%;

[0039] Hydroxyacrylate 4%;

[0040] 8-Hydroxyquinoline-5-sulfonic acid 0.5%.

[0041] Add maleic anhydride and water to the reactor, and start to heat up; then mix the rest of the reaction materials and pump them into the elevated tank; when the temperature of the reactor reaches 100°C, add the materials in the elevated tank to the reactor at a constant speed, and complete the addition within 2 hours. A polymer containing a fluorescent group is obtained.

[0042] 2. Label the preparation of environmentally friendly scale and corrosion inhibitors

[0043] Ingredients in the following parts by weight:

[0044] 20 parts of polymers containing fluorescent groups;

[0045] 40 parts of carboxylate polymers;

[0046] 2 parts of azole substances;

[0047] Compound amine substance...

Embodiment 2

[0052] 1. Preparation of polymers containing fluorescent groups

[0053] Take the following amount of raw materials:

[0054] Maleic anhydride 62%;

[0055] Acrylic 24%;

[0056] Acrylonitrile 6%;

[0057] Hydroxyacrylate 7%;

[0058] Ph-Hydroxybenzoic Acid 1%.

[0059] Add maleic anhydride and water to the reactor, and start to heat up; then mix the rest of the reaction materials and pump them into the high-level tank; when the temperature of the reactor reaches 100°C, add the materials in the high-level tank to the reactor at a uniform speed, and complete the addition in 3 hours. A polymer containing a fluorescent group is obtained.

[0060] 2. Label the preparation of environmentally friendly scale and corrosion inhibitors

[0061] Ingredients in the following parts by weight:

[0062] 25 parts of polymers containing fluorescent groups;

[0063] 30 parts of carboxylate polymers;

[0064] 2 parts of azole substances;

[0065] Compound amine substances 2 parts;

[...

Embodiment 3

[0070]1. Preparation of polymers containing fluorescent groups

[0071] Take the following amount of raw materials:

[0072] Maleic anhydride 32%;

[0073] Acrylic 20%;

[0074] Acrylonitrile 5%;

[0075] Hydroxyacrylate 6%;

[0076] 5-aminopyrazine-2-carboxylic acid 0.8%.

[0077] Add maleic anhydride and water to the reactor, and start to heat up; then mix the rest of the reaction materials and pump them into the elevated tank; when the temperature of the reactor reaches 100°C, add the materials in the elevated tank to the reactor at a constant speed, and complete the addition within 2.5 hours. A polymer containing a fluorescent group is obtained.

[0078] 2. Label the preparation of environmentally friendly scale and corrosion inhibitors

[0079] Ingredients in the following parts by weight:

[0080] 30 parts of polymers containing fluorescent groups;

[0081] 50 parts of carboxylate polymers;

[0082] 3 parts of azole substances;

[0083] 3 parts of compound amin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com