Oil Molecular Distiller

A molecular distillation and oil technology, applied in the direction of oil/fat refining, fat production, etc., can solve the problems of waste of energy, unsatisfactory deacidification effect, high cost, etc., and achieve the goal of reducing plant construction costs, good deacidification effect, and cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

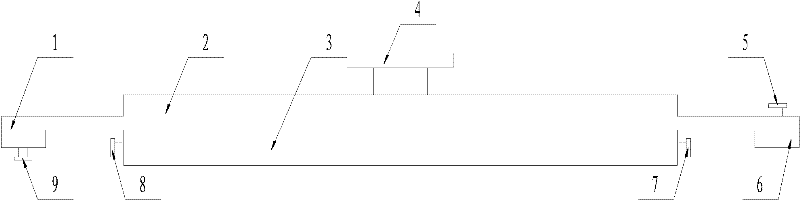

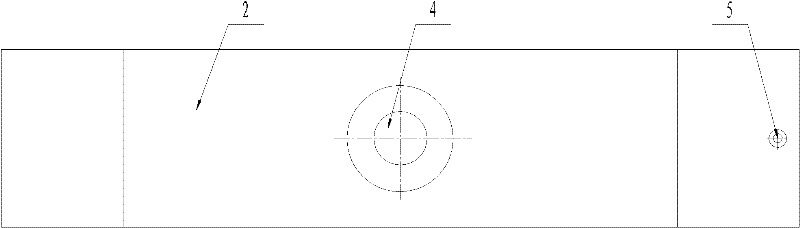

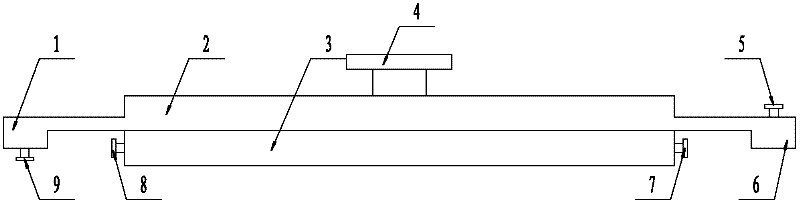

[0010] The present invention will be further described below in conjunction with the accompanying drawings:

[0011] A grease molecular distiller, comprising an oil chamber 2 and a heat-conducting oil chamber 3, the oil chamber 2 is provided with a chamber A 6 and a chamber B 1, the crude oil inlet 5 is located on the upper part of the chamber A 6, and the product oil outlet 9 It is located at the lower part of the chamber B 1; the heat-conducting oil chamber 3 is provided with a heat-conducting oil inlet 8 and a heat-conducting oil outlet 7.

[0012] When the present invention is installed, the inlet end of the crude oil is raised, so that the whole device is inclined at an included angle of 30 degrees. The vacuum port 4 is connected to the vacuum system; the crude oil inlet 5 is connected to the crude oil pump to supply oil to the equipment; the product oil outlet 9 is connected to the next deodorization process; the heat transfer oil inlet 8 is connected to the heat transfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com