Modularized mfg. process factory building for liquid crystal display

A liquid crystal display, modular technology, applied in the direction of instruments, industrial buildings, optics, etc., to achieve the effect of improving the safety of moving machines, not compressing the construction period, and increasing the speed of moving machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention provides a process-oriented modular factory building for liquid crystal displays.

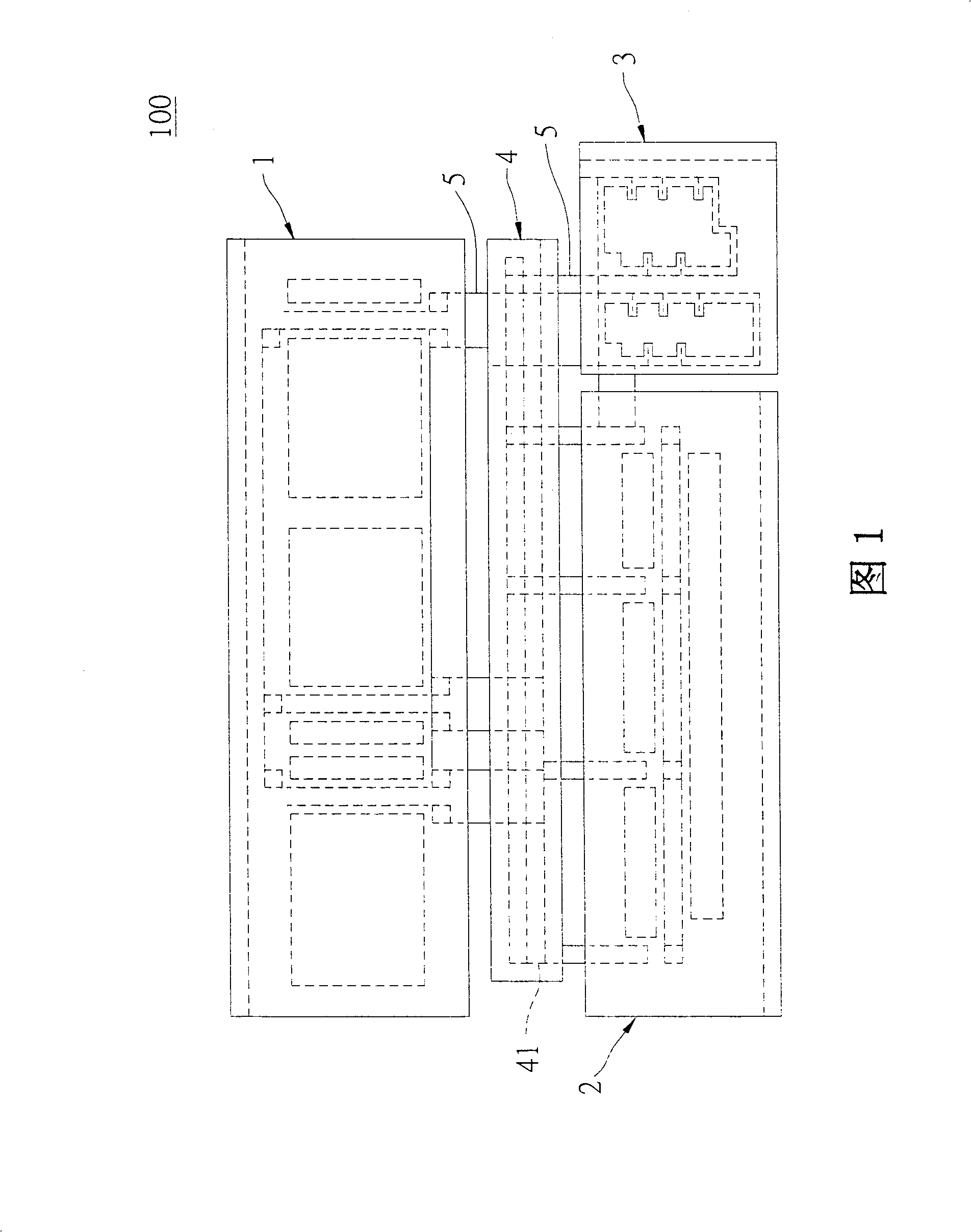

[0044] Please refer to FIG. 1 , which is an embodiment of the manufacturing process (Array) of thin film transistors used in the manufacture of liquid crystal displays in the plant, which is described as follows.

[0045] The workshop 100 for manufacturing liquid crystal displays such as TFT-LCD (Thin Film Field Effect Transistor Liquid Crystal Display) implements manufacturing processes including film formation, yellowing, etching and stripping.

[0046] Among them, the film-forming process is a high-calorie production process, which requires low cleanliness (class 10000), and is easily polluted by organic substances or acidic substances in terms of purity. In other words, it is a "pollution sensitive".

[0047] The production process of yellow light is easily affected by micro-vibration and temperature / humidity (sensitive to micro-vibration and temperature / humidit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com