Process for preparing biological diesel oil by utilizing canal mud

A technology of biodiesel and process method, applied in the field of energy, can solve problems such as high cost, occupying farmland, and high sales price, and achieve the effect of reducing the construction capital, saving cultivated land, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

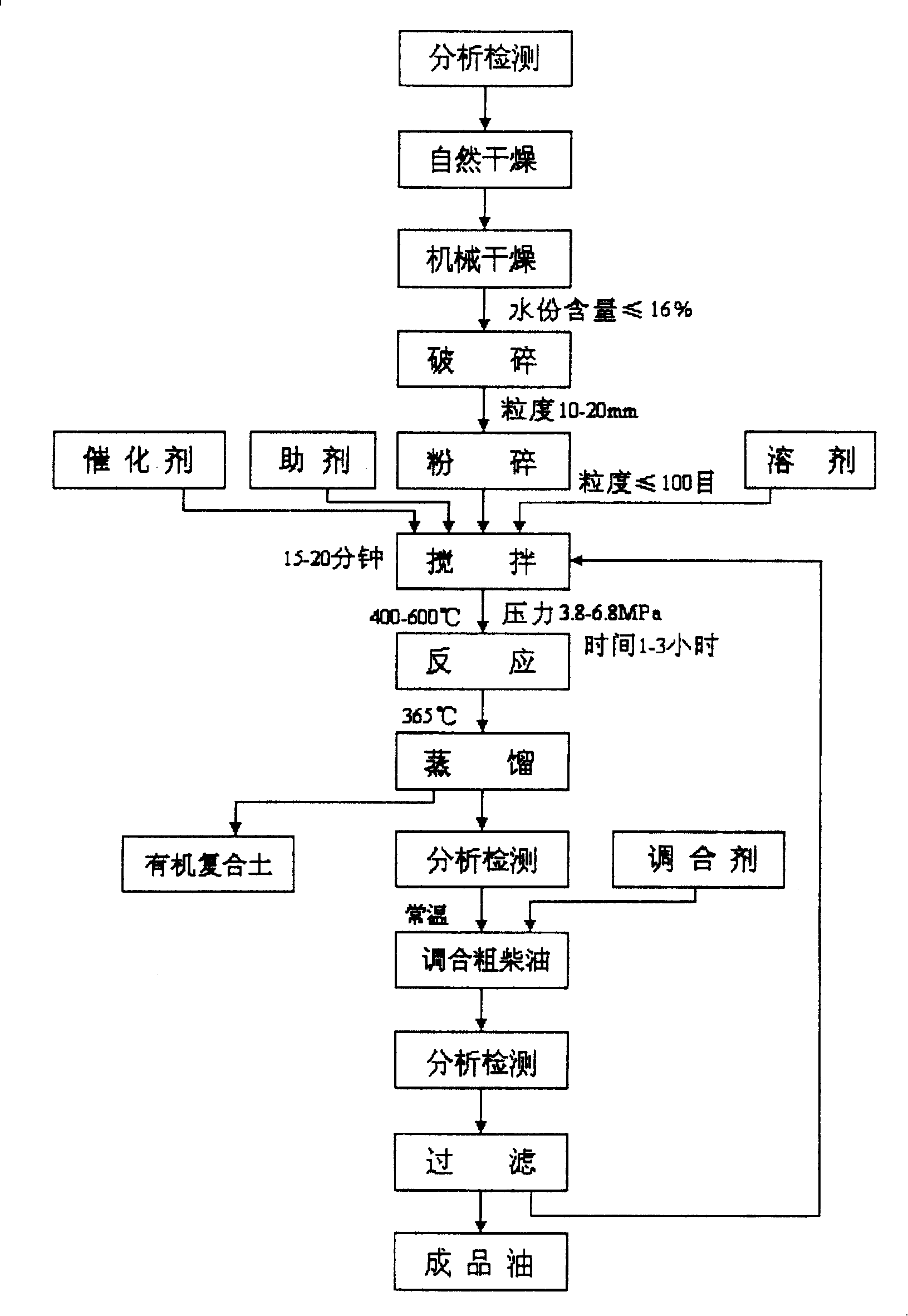

[0020] The process method of the present invention is composed of natural drying, mechanical drying, crushing, crushing, stirring, reaction, distillation, blending gas oil, detection, and filtration; the formula components and percentage content of raw materials: river mud 70.5, solvent 20, additive 8.5, catalyst 1; the river mud is the silt of Dianchi Lake in Kunming, or the river mud of the Pearl River and Shenzhen River, in which the organic component is 60%; the solvent is rapeseed oil or soybean oil; the auxiliary agent is methanol or sixteen Alcohol; the specific process method is that the river mud is first analyzed and tested, and the river mud whose components meet the index requirements is used as a raw material and transferred to the next step of the process; first, it is naturally dried, and the river mud is exposed to sunlight and weathering. When a large number of cracks appear, it can be transferred to the next step. Enter the next process; after that, carry out ...

Embodiment 2

[0024] River mud is used as raw material to produce biodiesel. The river mud originates from Taihu Lake and its watershed. According to the material component formula and weight percentage (%) provided by the present invention, various materials are prepared, according to river mud 63.5, solvent 30.0, auxiliary agent 5.5, catalyst 1, weighing river mud Mud 635kg, solvent 300kg, auxiliary agent 55kg, catalyst 10kg; the solvent is peanut oil or castor oil, the auxiliary agent is cetyl alcohol, the catalyst is aluminum chloride, after mixing, enter the agitator, and after fully stirring for 10 minutes, transfer to the reaction Operation, the reaction kettle was heated to 500 degrees, the pressure was 5.3MPa, and the time was 2 hours; the technical parameters of other procedures were all the same as in Example 1.

Embodiment 3

[0026] Use river mud as raw material to produce biodiesel. The river mud adopts the underwater sediment of Haihe River. Raw material formula provided by the present invention and content (weight %) ratio thereof, river mud 56.5, solvent 40.0, auxiliary agent 2.5, catalyst 1; Weigh each component, river mud 565kg, solvent corn oil 400kg, auxiliary agent cetyl alcohol 25kg, catalyst aluminum chloride 10kg; Stirring time is 20 minutes, and 600 degree of temperature of reaction, reaction pressure 6.8MPa, the reaction times is 3 hours; The technical parameters of other operations and processing method are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com