Carding machine deflector

A technology of diversion device and carding machine, which is applied in the direction of deburring device, textile and paper making, fiber treatment, etc. It can solve the problems of hair particles, reduce the operation rate and production rate of carding machine, and is not conducive to short-hair carding. Achieve the effects of reducing hair particles, improving operation rate and production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

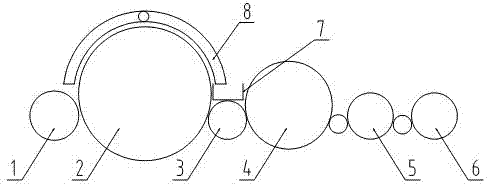

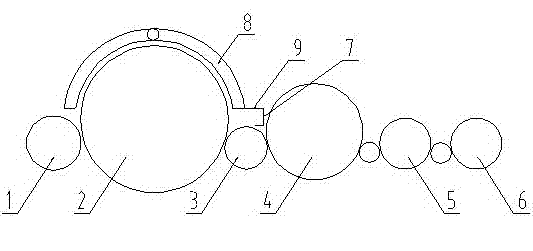

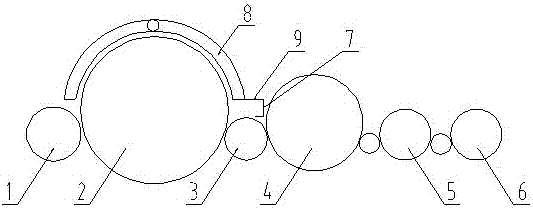

[0019] See figure 2 , The present invention relates to a flow guiding device for a carding machine, which comprises a large cylinder 2 and a two-breasted cylinder 4, and a flow deflector 8 is arranged above the large cylinder 2 and the large cylinder 2 and the second-breasted cylinder The opening roller 3 is arranged between the opening roller 3, and the trash removal groove 7 is provided above the opening roller 3. The front half of the trash removal groove 7 is cut, and the top of the trash removal groove 7 is provided with a windshield 9 which is The wind hood 9 is connected with the deflector 8.

[0020] When the carding machine is working, the airflow generated in the large cylinder 2 is blocked by the windshield 9 and then changes direction. It is cut from the trash slot 7 and is guided to the bottom of the carding machine through the opening roller 3, which is beneficial to the carding of short hairs. , Make the wool net better, reduce the wool particles, improve the run...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com