Rear stable tail wagging mechanism of excavator

A technology of roadheader and post-stabilization, which is applied to slitting machinery, earth-moving drilling and mining, etc., can solve the problem of inability to realize fine-tuning of the tail of the roadheader, and achieve the effects of flexible action, good stability and large contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

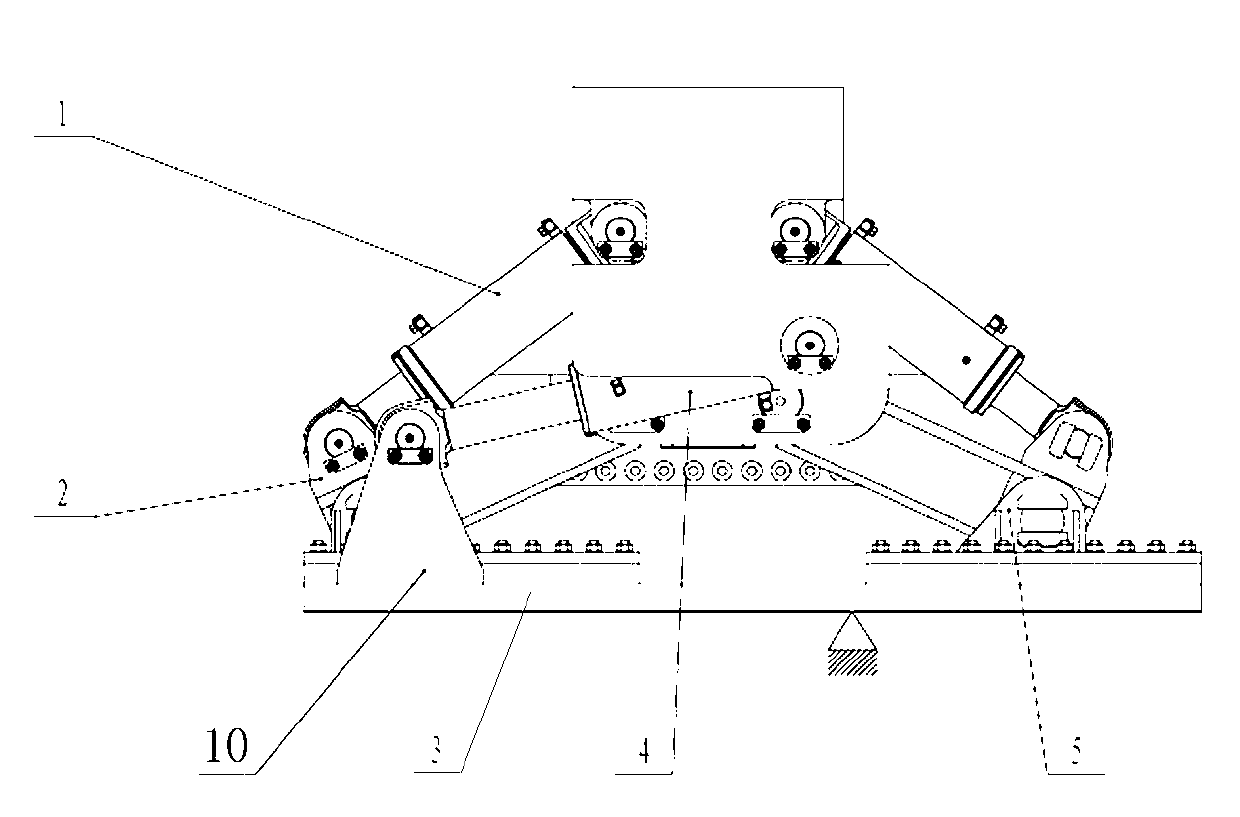

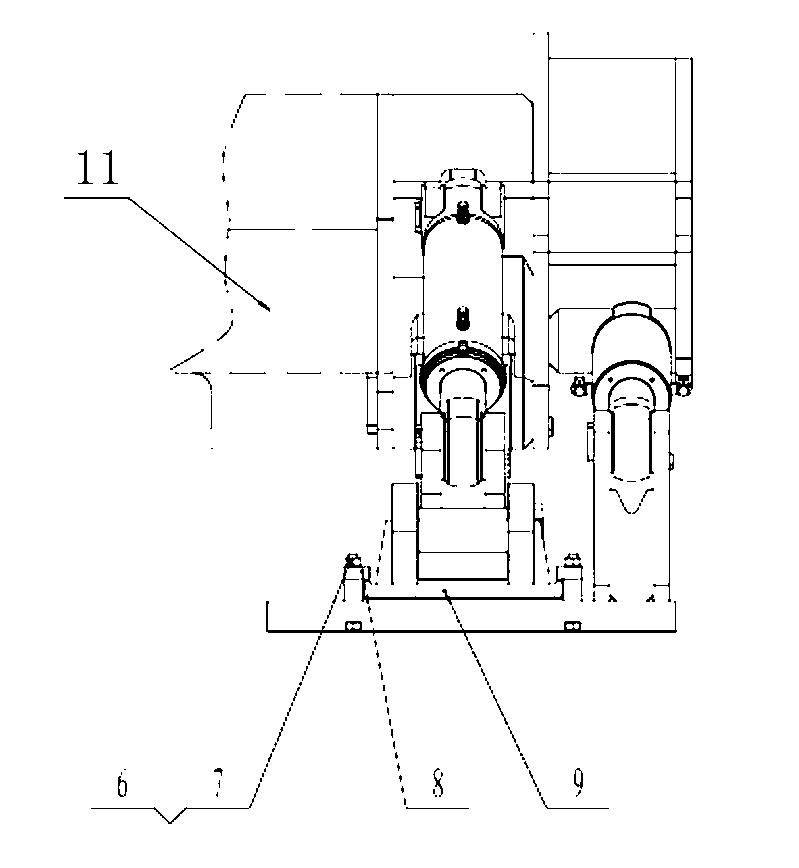

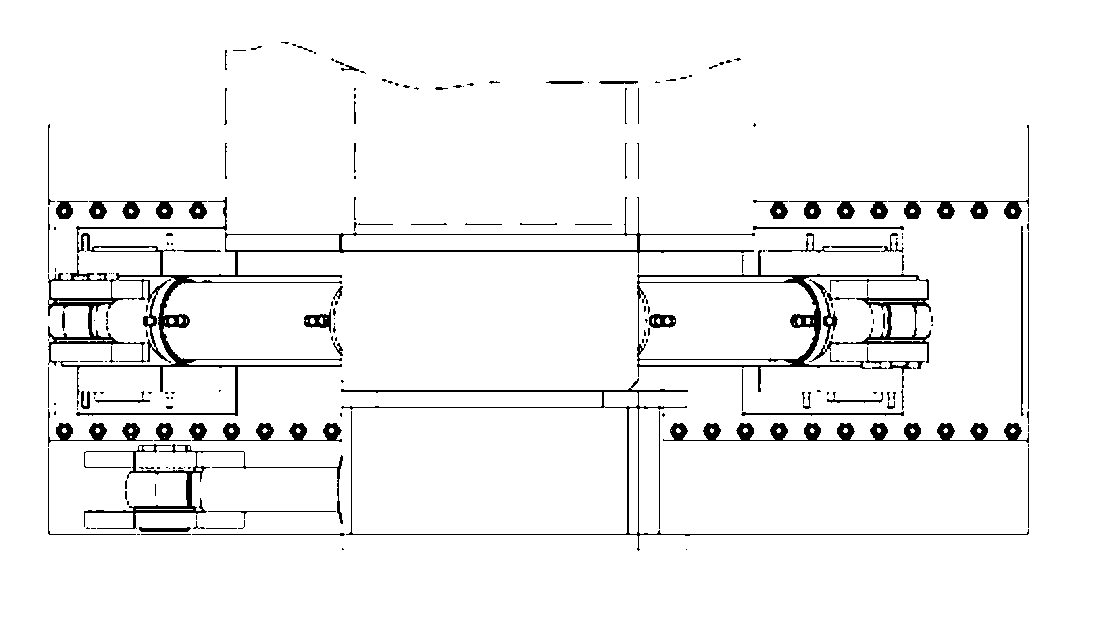

[0014] The rear stabilizing swing tail mechanism of the roadheader includes two rear support cylinders 1 connected to the tail of the roadheader body 11, and the piston rod end of the rear support cylinder 1 is hingedly connected with the rear support leg 2, which is characterized in that the two rear support legs 2 are respectively Installed on the left sliding shoe 9 and the right sliding shoe 5, the left and right sliding shoes are supported on the support base plate 3 and can move relative to the support base plate 3, the support base plate 3 is provided with a support base 10, the support base 10 and the swing oil cylinder 4 The end of the piston rod is hinged, and the cylinder barrel of the swing cylinder 4 is hinged with the tail of the boring machine body 11 . Two pressing plates 8 are respectively arranged on the positions correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com