An open discontinuous vane pump

A vane pump and vane technology, applied in the field of open discontinuous vane pump impeller, can solve the problems of increased vane wear, affecting the normal flow of liquid, affecting the stability and life of the pump, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

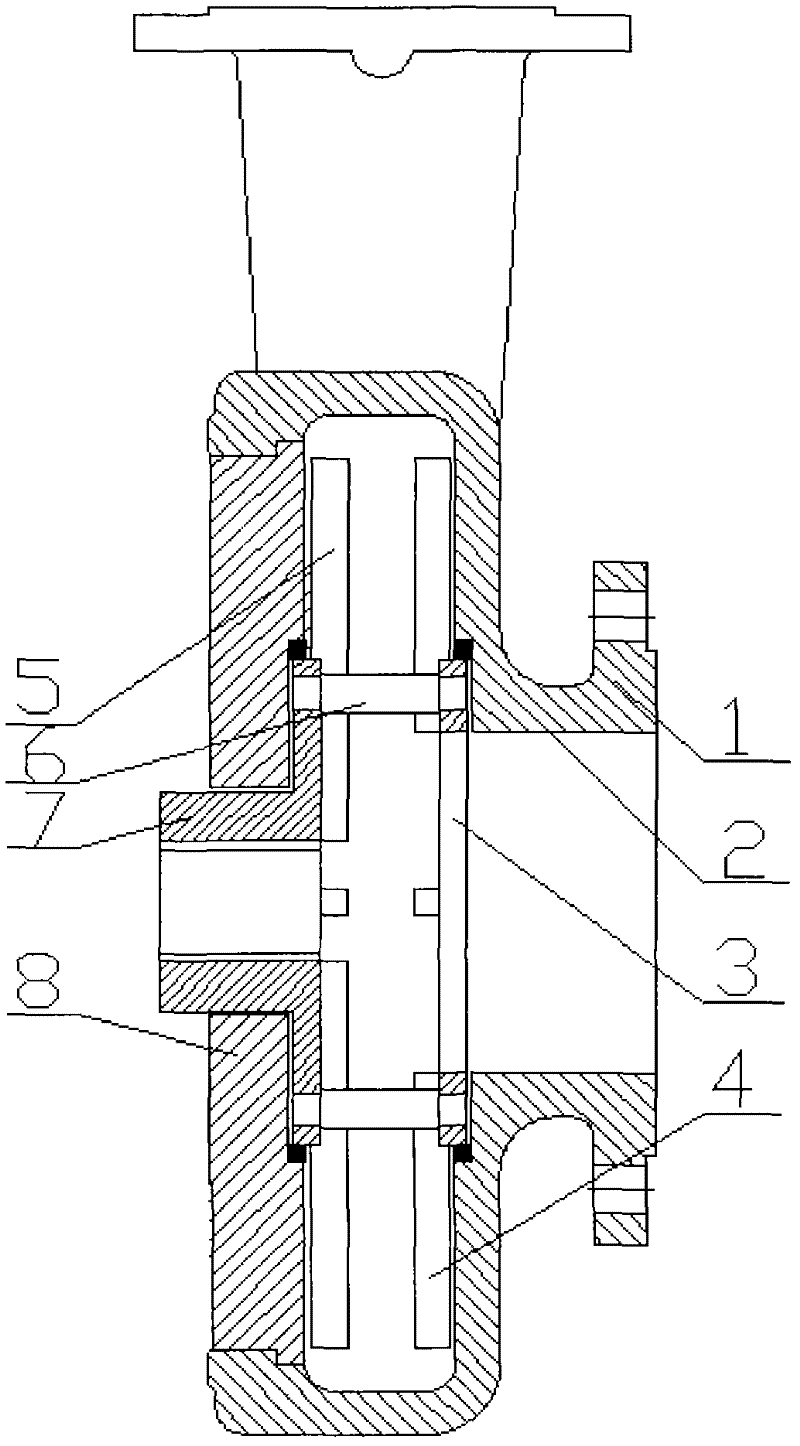

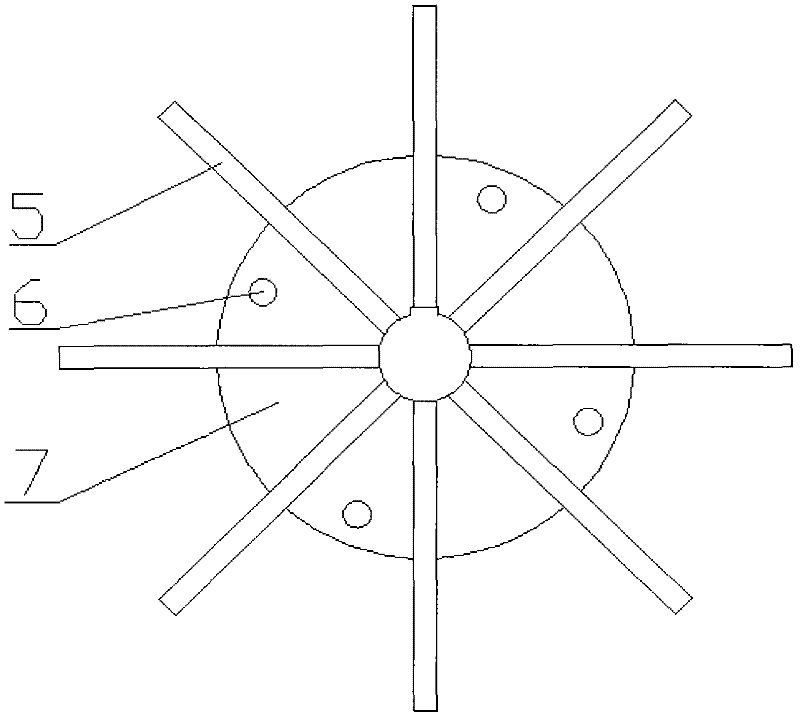

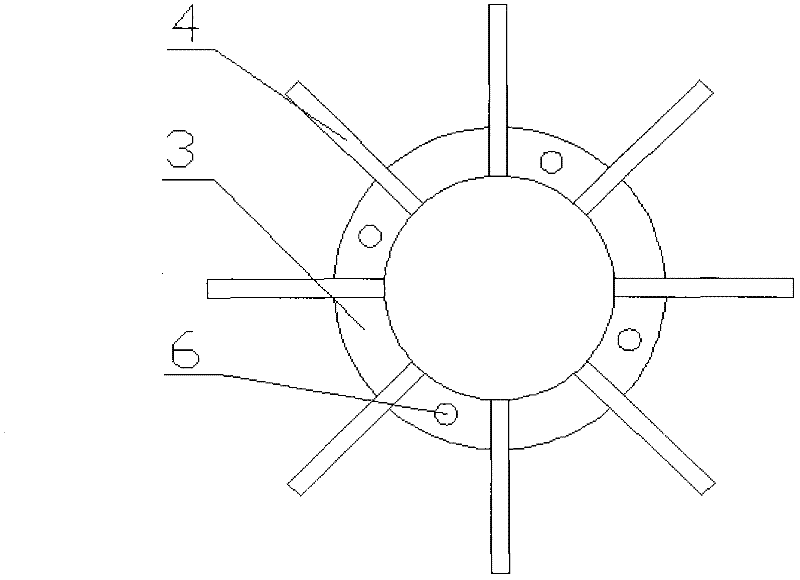

[0017] refer to figure 1 , This example includes the pump casing 1, the mouth ring 2, the driven ring 3, the driven vane 4, the driving vane 5, the connecting arm 6, the driving disc 7 and the rear pump cover 8. The drive disc rotates at high speed driven by the drive shaft, the connection between the drive disc 7 and the driven ring 3 is realized through the connection arm 6 to drive the driven ring 3 to rotate together, and the driven blade 4 is consolidated with the driven ring 3, the active vane 5 is fixed on the drive disc 7. The driving disc 7 is in clearance fit with the mouth ring on the rear pump cover 8 , and the driven ring 3 is in clearance fit with the mouth ring 2 on the pump casing 1 . The height of the driving vane 4 and the driven vane 5 is recommended to be less than 1 / 4 of the width of the pump chamber, and the distance between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com