steering shaft

A technology of steering transmission shaft and shaft, applied in the direction of rotating motion shaft, etc., can solve the problems of transmission and inability to realize torque, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

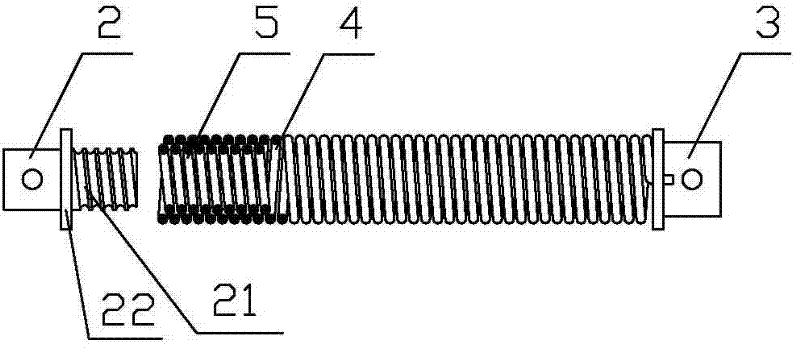

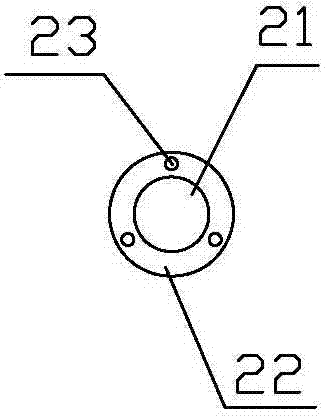

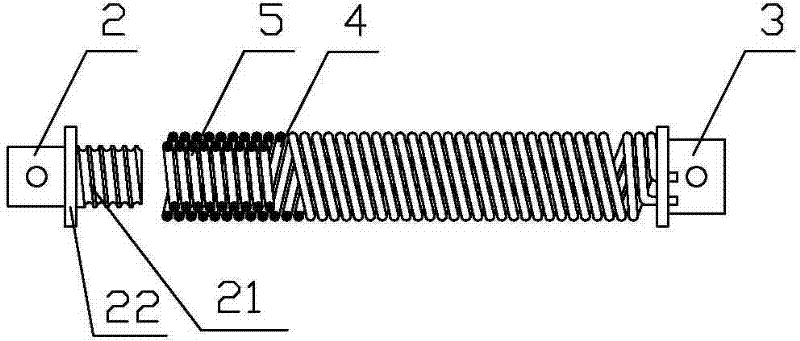

[0012] As shown in the figure, the steering transmission shaft according to the present invention includes a shaft and connecting pieces 2 and 3 connected to both ends of the shaft. The structure of the connecting pieces 2 and 3 can be adopted as required figure 2 The shown cylinder may also adopt a columnar structure such as a quadrangular prism, a pentagonal prism, or a hexagonal prism. The shaft includes an outer rod 4 and an inner rod 5, the outer rod 4 and the inner rod 5 are coil springs, the inner rod 5 is coaxially inserted in the inner cavity of the outer rod 4, in order to achieve a better use effect, The outer diameter of the inner rod 5 should be the same as or close to the inner diameter of the outer rod 4 . The helical directions of the inner rod 5 and the outer rod 4 are opposite, that is, one of them is a left-handed spring, and the other is a right-handed spring. The inner rod 5 and the outer rod 4 can adopt a monofilament spring, that is, a spring wound by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com