Testing machine for testing the durability of materials in a high-pressure hydrogen environment

A technology of high-pressure hydrogen and testing machine, which is applied in the application of stable tension/pressure to test the strength of materials, analyze materials, and measuring devices. It can solve the problems of distortion of measurement results and difficulty in accurate measurement, and achieve the effect of avoiding interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

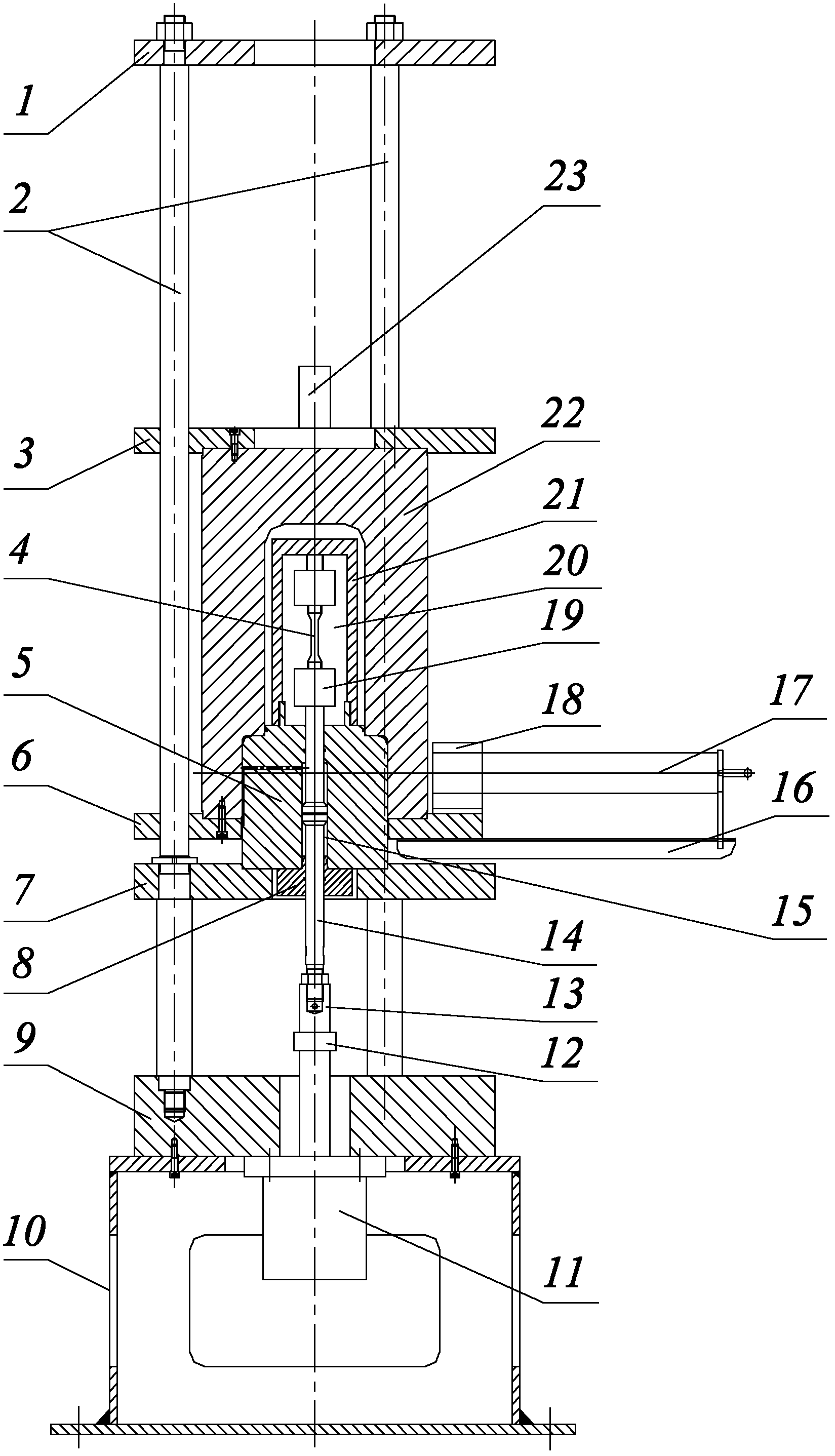

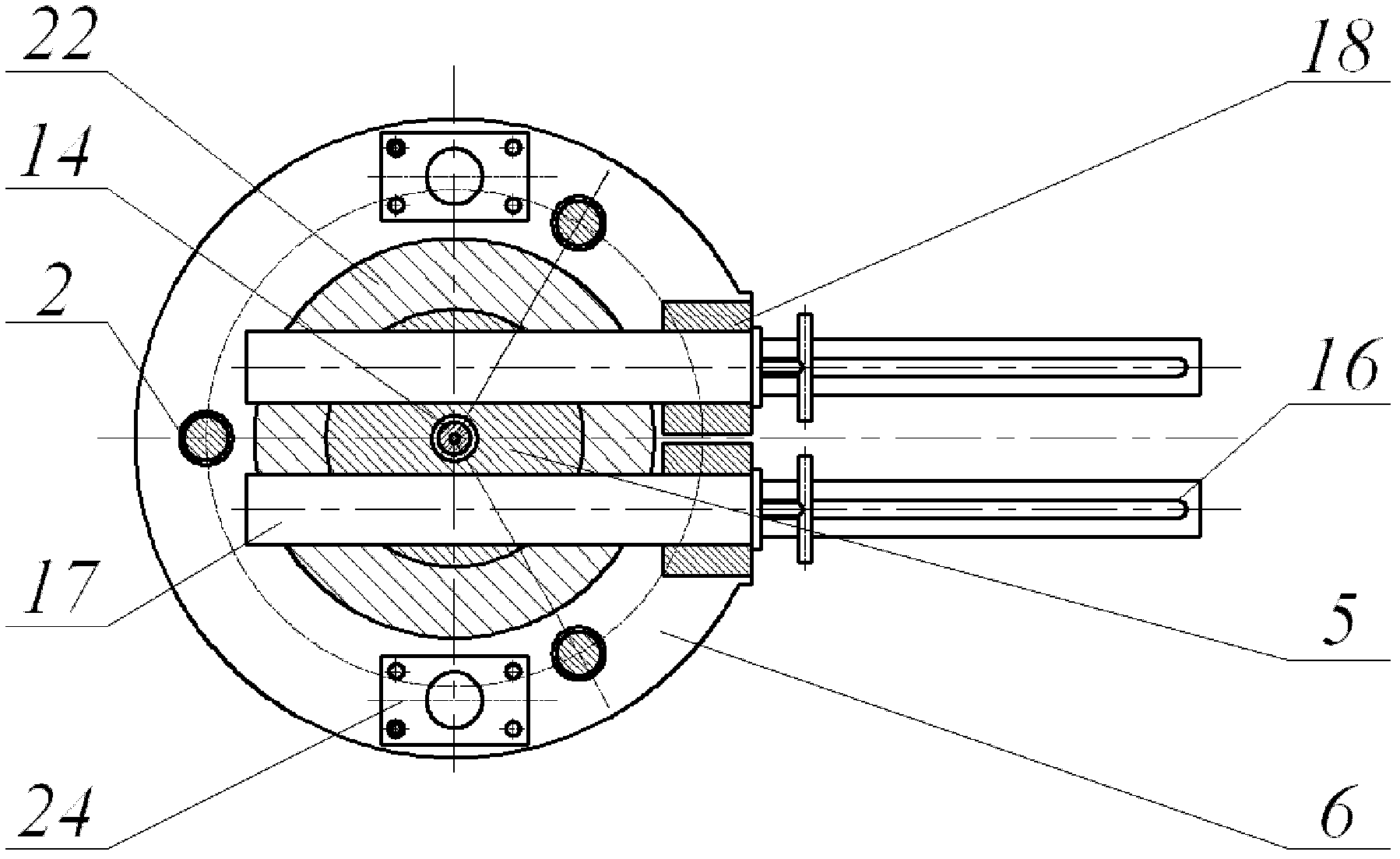

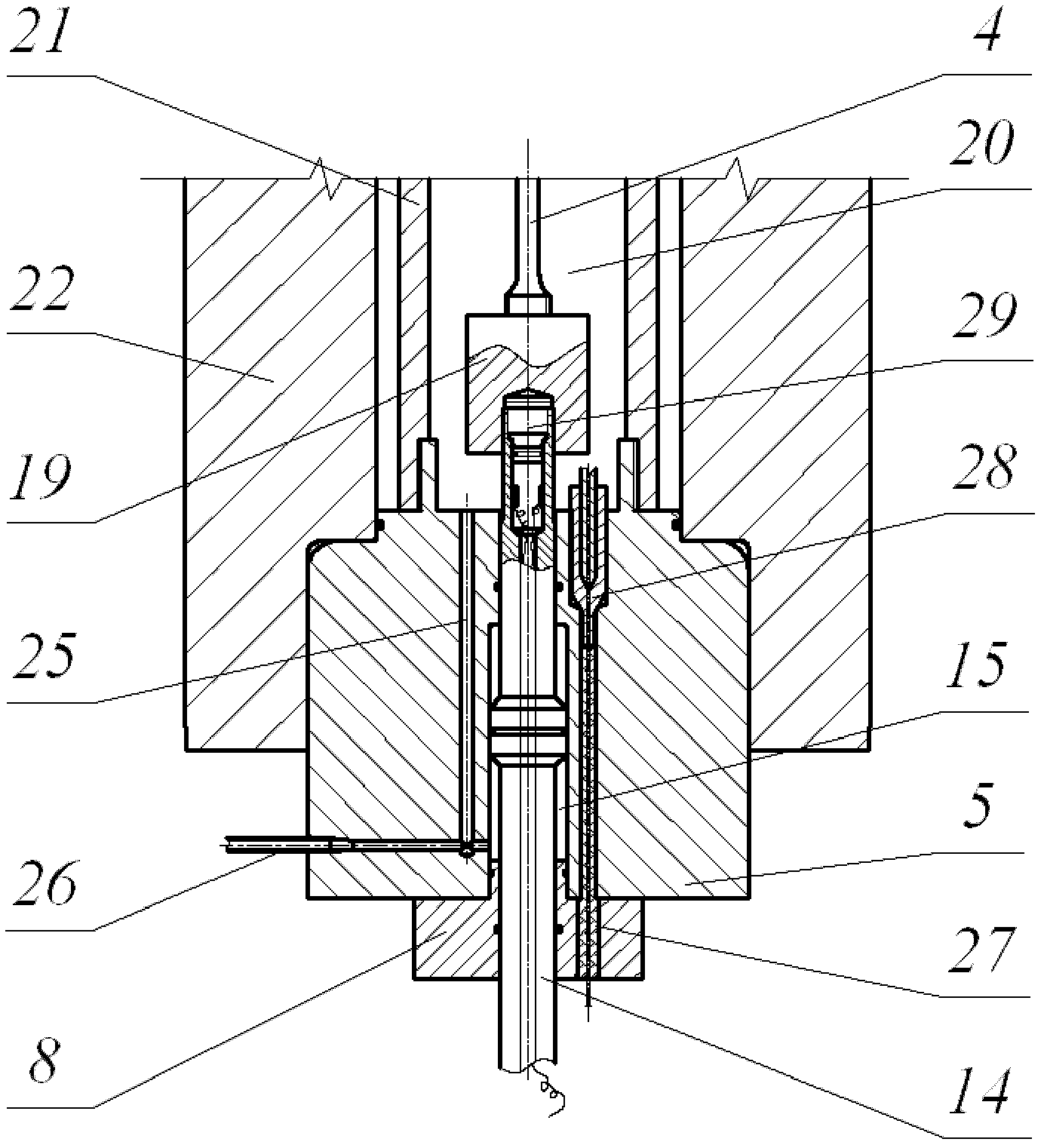

[0022] This embodiment provides a material durability testing machine in a high-pressure hydrogen environment. The testing machine includes a high pressure test chamber 20 composed of a box body 22 and a sealing seat 5 , a balance chamber 15 composed of a loading rod 14 and a sealing seat 5 and a balance chamber sealing bottom cover 8 , a sample load measuring device, and a box body lifting device. After the box body 22 is matched with the sealing seat 5, the pin 17 is inserted into the pin hole to limit the relative movement of the box body 22 and the sealing seat 5, so as to realize the joint bearing and sealing of the two. One end of the loading rod 14 is connected to the tested sample 4 through the sample holder 19, and the other end is connected to the power output end of the testing machine, which can realize the loading of the sample. Pull out the pin 17, activate the box body lifting device, and move the box body 22 up, so that the sample 4, the bracket and the fixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com