Mechanical trimming device and trimming method

A mechanical trimming and mechanical technology, applied in the direction of valve devices, mechanical equipment, valve operation/release devices, etc., can solve the problems of space requirement, low thread surface roughness, expensive, etc., and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

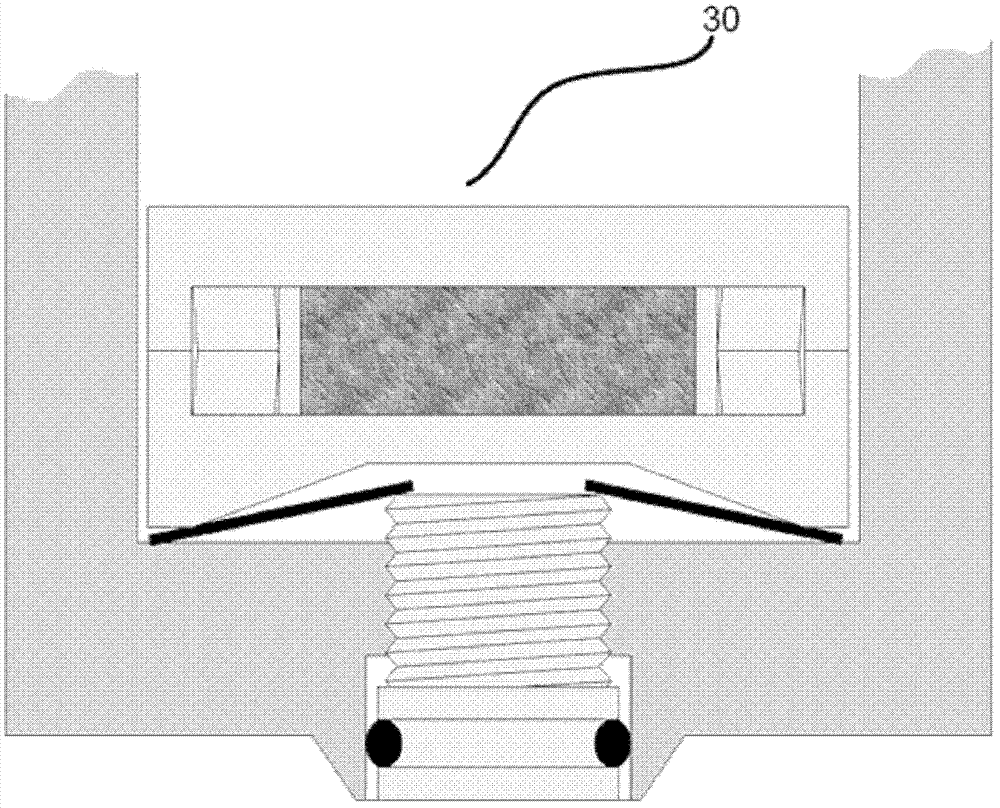

[0042] Other embodiments may also include situations where very small length adjustments are required, eg other types of actuator units.

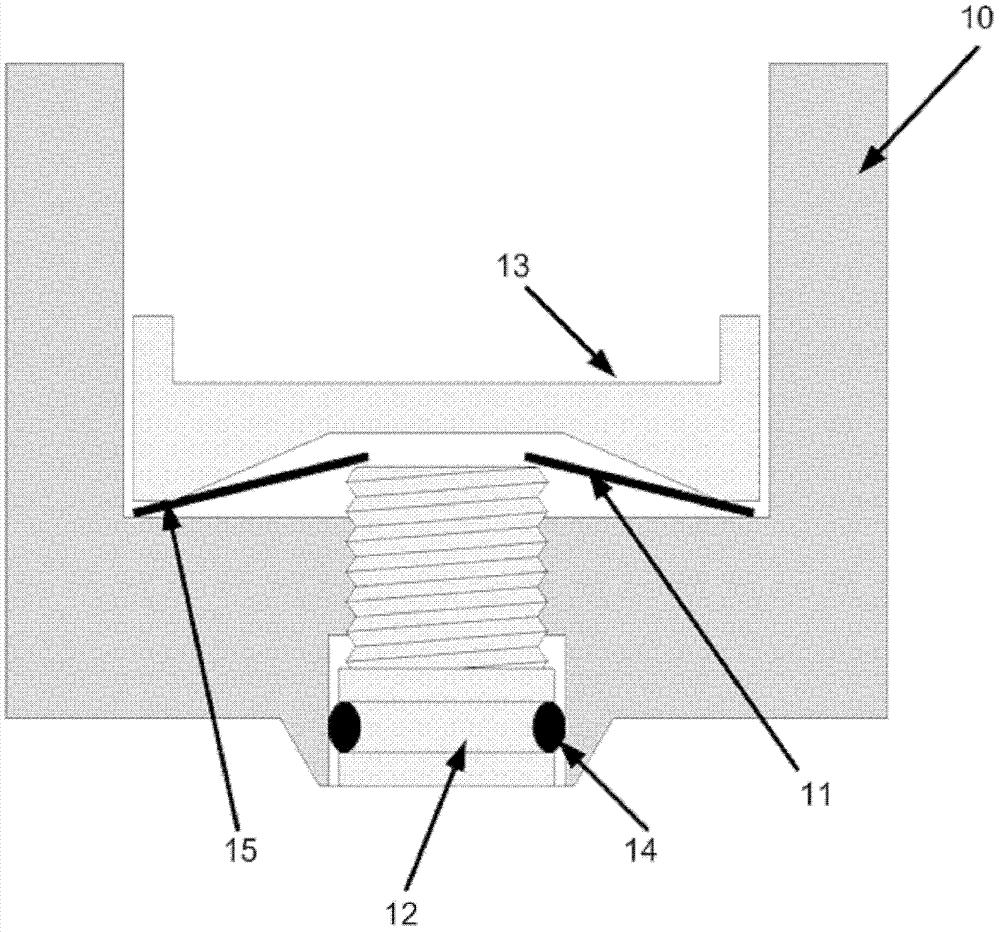

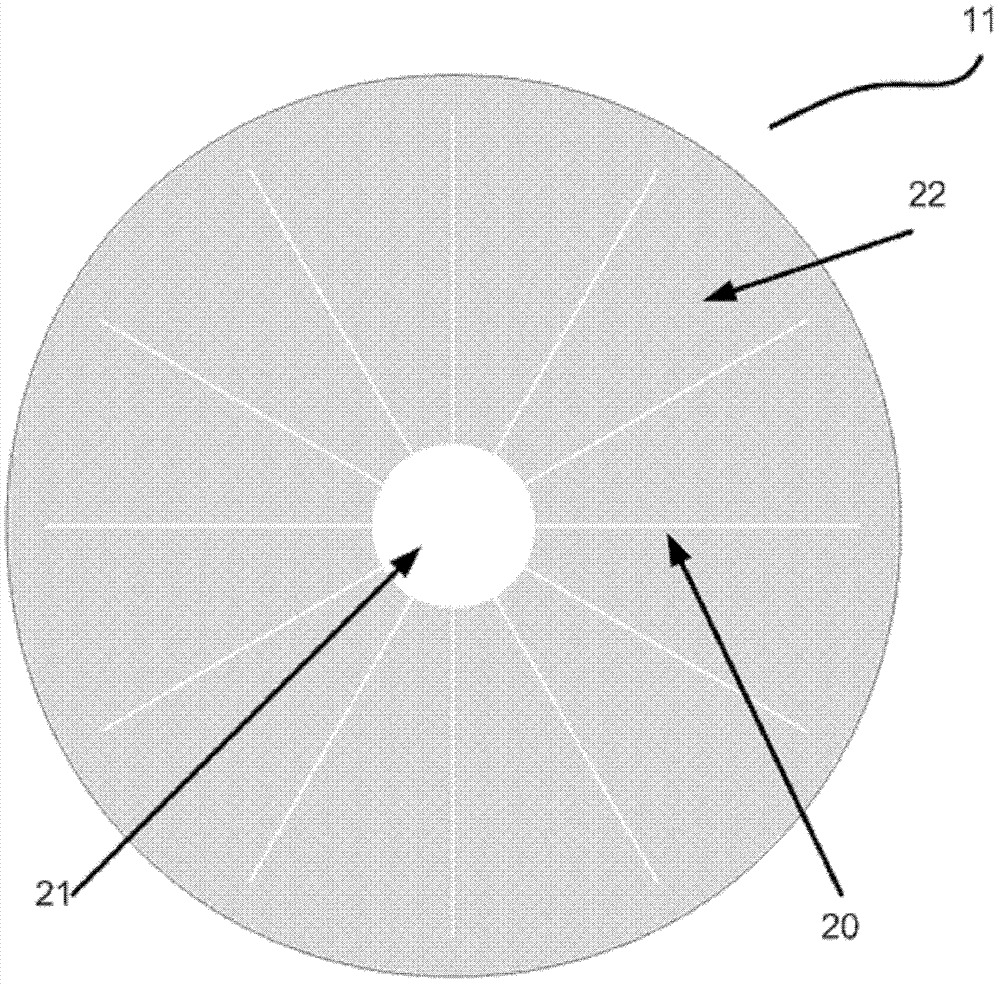

[0043] In another aspect, the present invention also provides a method for dressing in a direction normal to the surface of a mechanical dressing device, the method comprising adjusting a screw to lift the center of the disc-like member so that the disc-like member operates as a lever , the lever includes a first distribution contact point and a second distribution contact point, the first distribution contact point is in contact with the edge of the cavity of the second body, and the second distribution contact point is in the cavity of the disc-shaped member The outer edge of the cavity is in contact with the surface of the first body, the first body is a movable body, and the second body moves relative to the first body. Further, the method uses the above-mentioned mechanical trimming device to mechanically trim the stroke of the piezoel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com