Modular combined rubber track

A rubber crawler and rubber belt technology, which is applied in the field of machinery, can solve the problems of large pavement damage, high noise, and low adaptability to complex road surfaces, and achieve the effects of preventing accumulation, reducing operating noise, and improving passability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

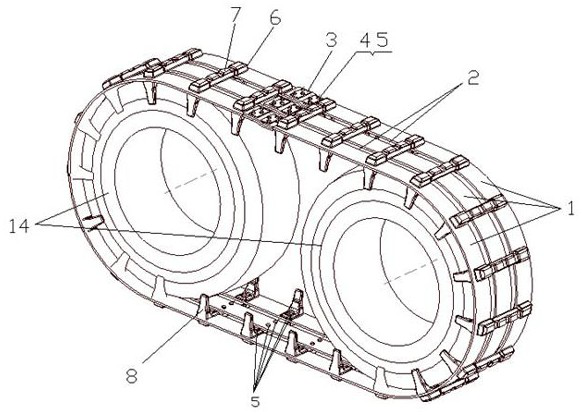

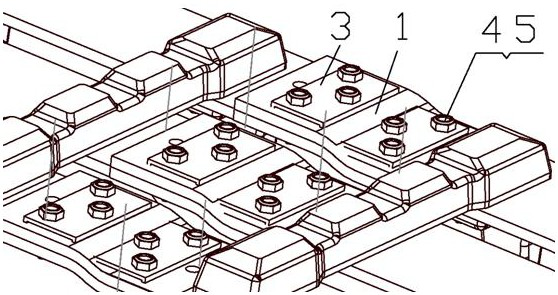

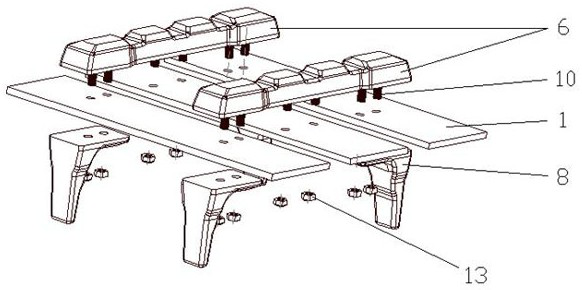

[0023] like Figure 1-Figure 7 As shown, a modular combination rubber track of the present invention includes three rubber belts 1 arranged at intervals in parallel. The intervals between each form a mud escape groove 2. On the outer surface of the rubber belt 1, there are more than two pattern blocks 6 arranged in parallel along the length direction of the rubber belt 1. Any pattern block 6 is connected to three rubber belts 1. The length direction of the pattern block 6 is parallel to the width direction of the rubber belt 1, and more than two projections 7 are arranged at intervals along the length direction of the pattern block 6, and the inner surface of the rubber belt 1 located on the outside is parallel to the circumferential direction. More than two first gear teeth 8 are arranged at intervals, and more than two second gear teeth are arranged at intervals in parallel along its circumference on the inner surface of the rubber belt 1 located on the inner side. The numbe...

Embodiment approach

[0039] 1. The rubber of the pattern block 6 and the skeleton 9 are vulcanized and formed through a mold and a flat press.

[0040] 2. The rubber of the retaining tooth 8, the fastening plate 11, and the vertical plate 12 are vulcanized and formed by a mold and a flat press, and are ready for use.

[0041] 3. After the rubber belt 1 is vulcanized and molded, holes are drilled according to the customer's size requirements for installing the second bolt 10 .

[0042] 4. After the tire 14 is inserted, the rubber belt 1 is overlapped and connected, and fixed by the backing plate 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com