Electric assembly

A technology for electrical components and sockets, applied in electrical components, battery pack components, circuits, etc., to achieve the effects of reduced contact resistance, reliable contact, maintenance and installation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

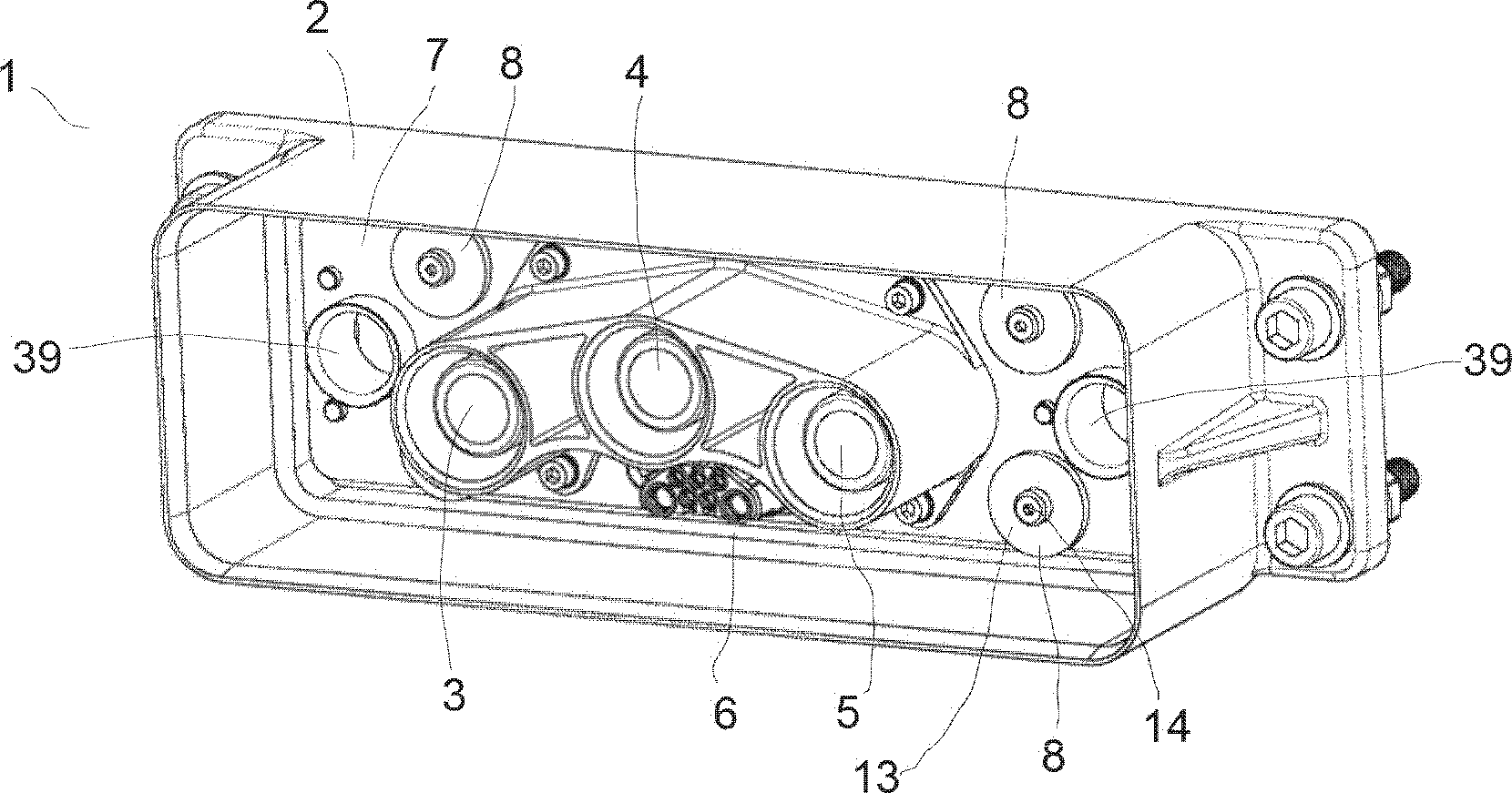

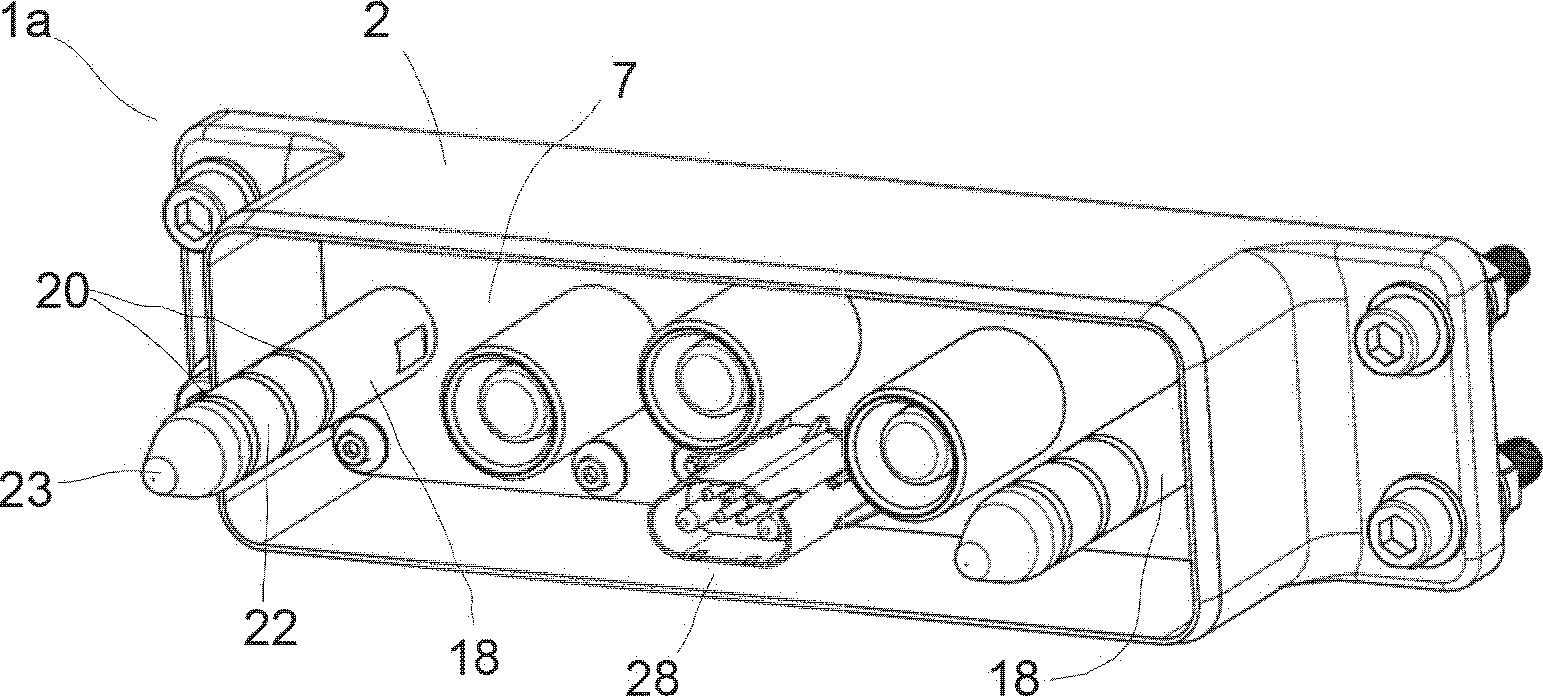

[0089] Refer to the attached Figures 1 to 11 Examples of the present invention will be described.

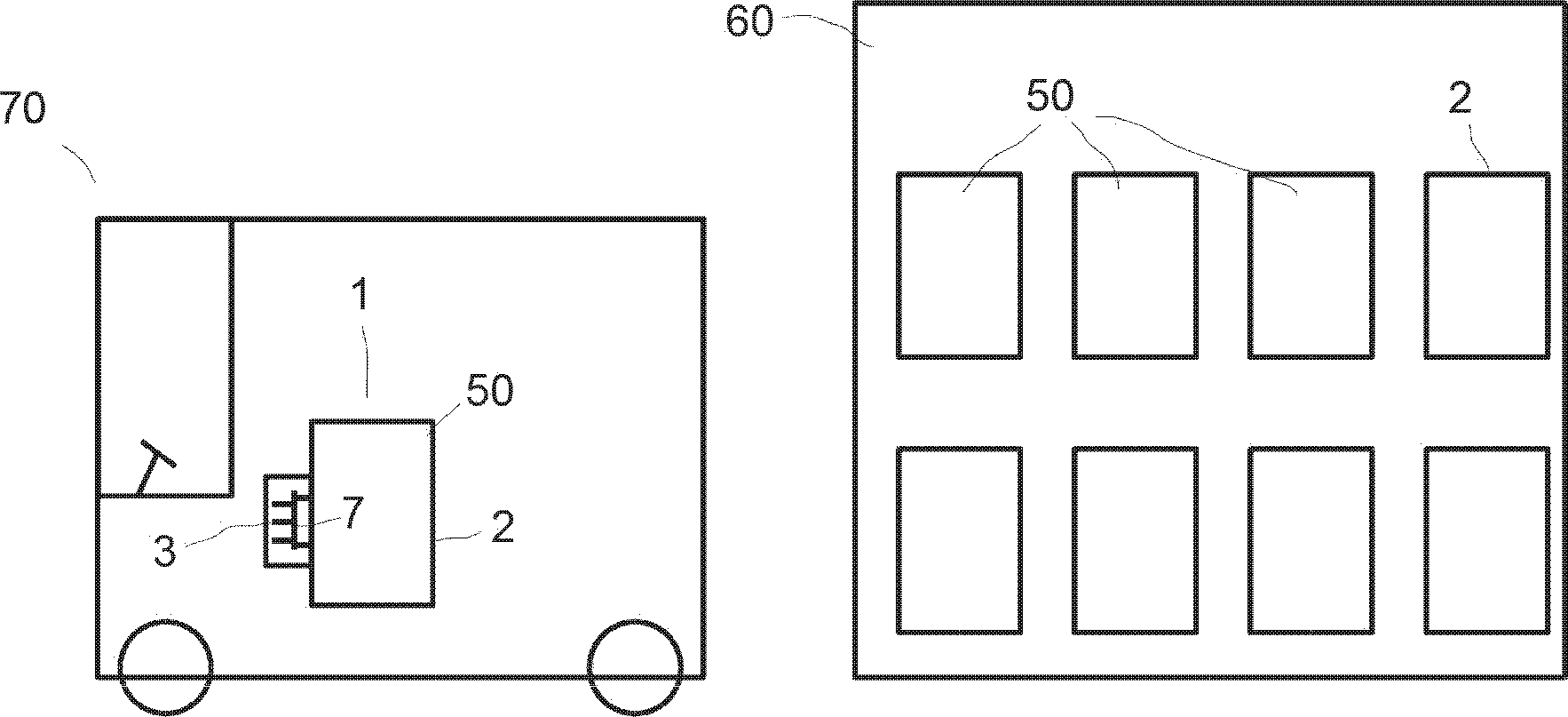

[0090] figure 1 is a schematic diagram showing a vehicle 70 and a charging station 60 . The vehicle 70 has a battery pack 50 which is replaceably provided on the vehicle 70 . A plurality of battery packs 50 may be mounted on the vehicle as necessary.

[0091] The battery pack 50 is here the electrical assembly 1 , which has a housing 2 and a plug-in portion 3 on the plug-in socket 7 .

[0092] In addition to using the electrical assembly 1 according to the invention on a vehicle, it can also be used on a stationary or other mobile device or device.

[0093] In this embodiment, the weight of the battery pack 50 as the electrical component 1 is as high as 100, 150 or even 200 kg. To replace the battery pack 50, a forklift (not shown) is used, which removes the battery pack 50 from the vehicle 70 and transports it to the charging station 60, which is configured, for example,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com