Injection-molded product and method of making the same

A technology of injection molding and manufacturing method, used in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve problems such as high cost, falling off, shell scratches, etc. The effect of the simple method of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

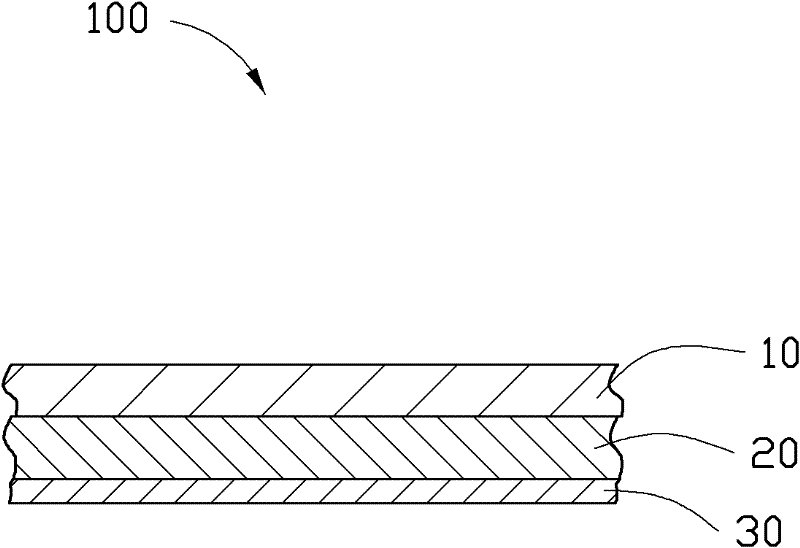

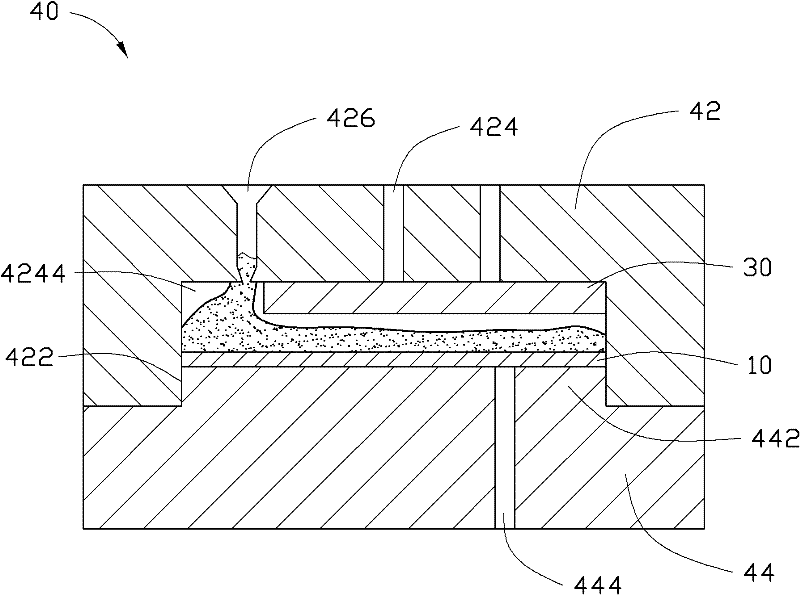

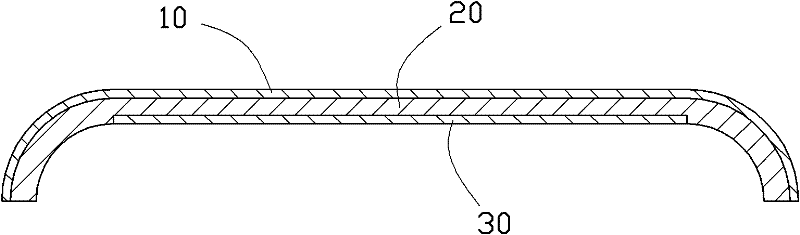

[0035] see figure 1 , a preferred embodiment of the injection molding product of the present invention is a mobile phone casing 100 . The mobile phone casing 100 includes a first surface layer 10 , namely the outer layer, a middle layer 20 and a second surface layer 30 , namely the inner layer.

[0036] The first surface layer 10 is a soft material layer, which can be a decorative layer such as leather, fabric, film, etc., and has both high texture and high wear resistance. Such as genuine leather, leather such as PU or PVC, various textiles or cloths such as cotton or polyester, or IML films pasted with adhesives and printed with patterns. The first surface layer 10 has a shape consistent with the outer surface of the part to be decorated.

[0037] Described middle layer is plastic layer, and this plastic layer 20 constitutes the main component part of described mobile phone housing 100, and it is made of injection molding resin material, can select as: polyvinyl chloride, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com