battery module

A battery module, battery technology, applied in secondary batteries, battery/battery traction, circuits, etc., can solve problems such as high energy overhead, adverse effects, easy damage, etc., and achieve high efficiency, rapid cooling, and good heat exchange. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

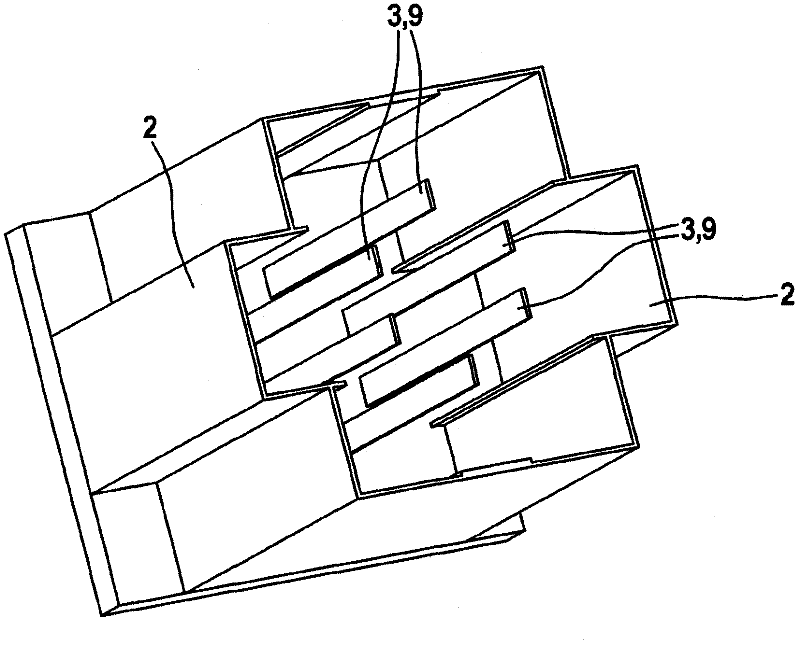

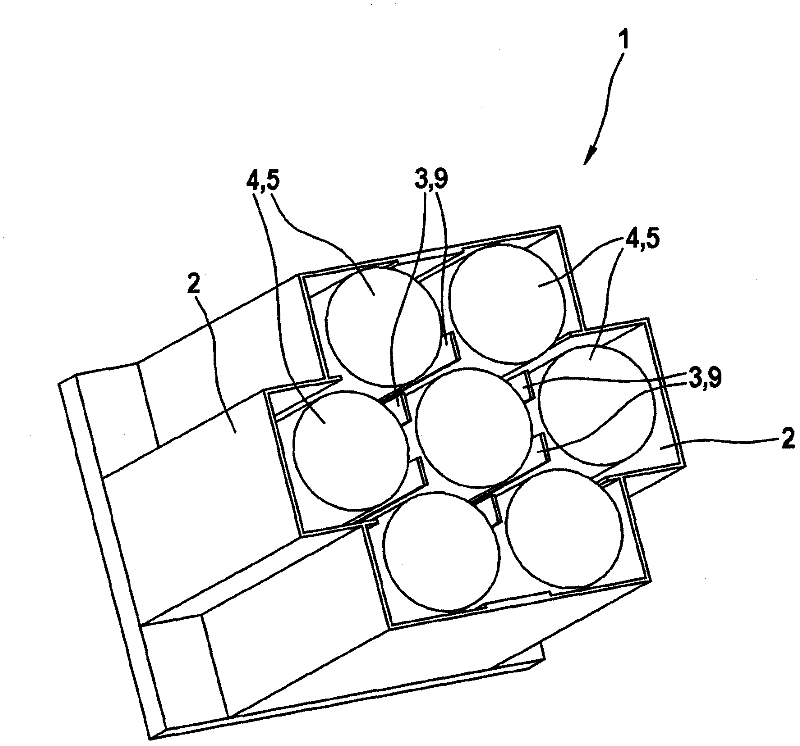

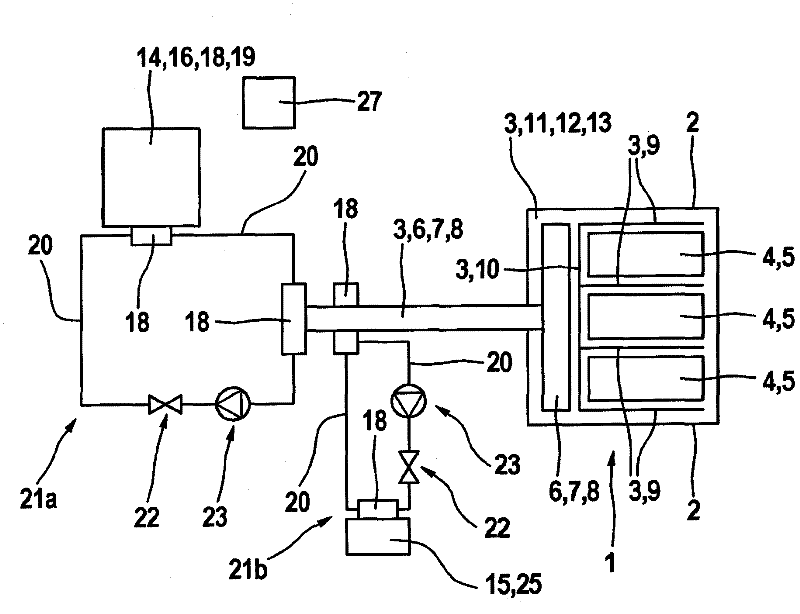

[0027] exist figure 1 A perspective view of a housing 2 of a battery module 1 for accommodating a battery 4 is shown in . exist figure 1 The upper wall of the housing 2 is not shown. The housing 2 consists of plastic and fins 9 made of copper are arranged inside the housing. Between the fins 9 and the housing 2 there is a battery 4 configured as a lithium-ion battery 5 ( figure 2 ). exist figure 1 and 2 Electrical lines for conducting current or supplying current to battery 4 are not shown. The cavities left between the cells 4 in the housing 2 are filled with a heat-conducting liquid 11, such as oil 12, especially silicone oil 13 ( image 3 ). The fins 9 and the silicone oil 13 have a high thermal conductivity, so that the heat dissipated on the surface of the cells 4 can be dissipated well and only small temperature differences occur between the cells 4 of the battery module 1 . The fins 9 and the silicone oil 13 are means 3 for temperature regulation, i.e. cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com