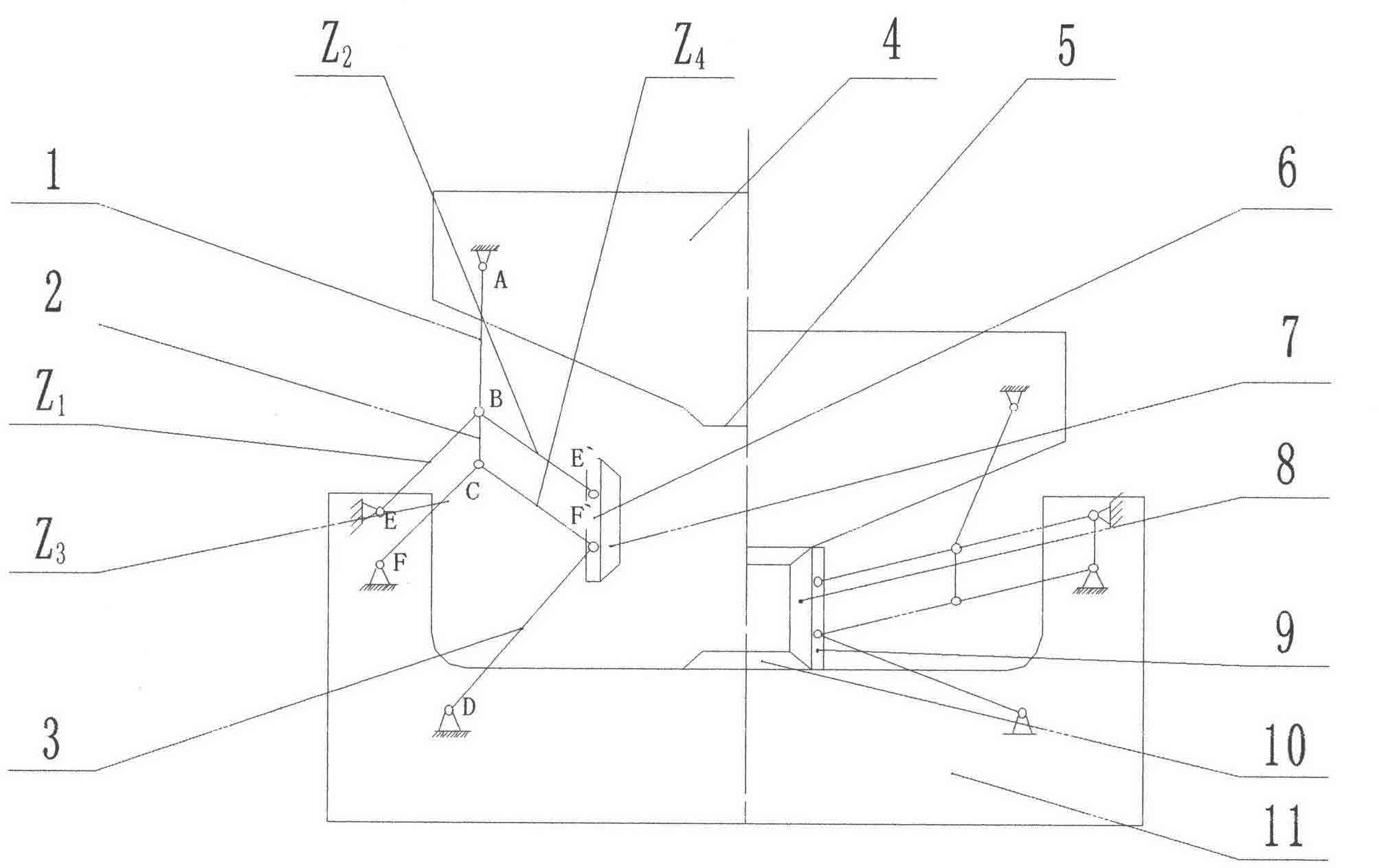

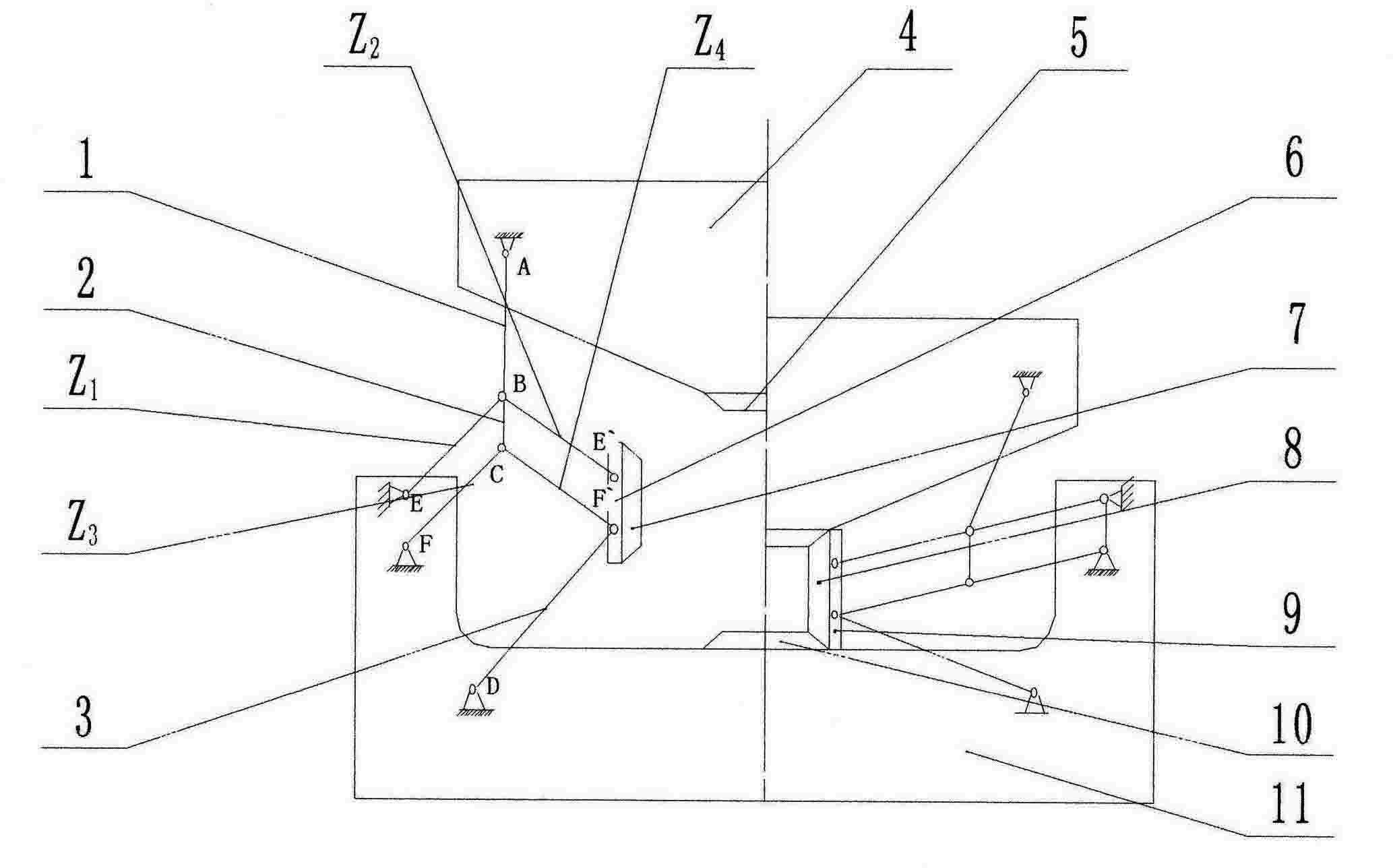

Double-toggle rod type four-hammer forging device

A technology of double toggle levers and four hammer heads, which is applied in the driving device of hammer, forging/pressing/hammer device, hammer, etc., can solve the problems of harsh working surface lubrication requirements, high friction force, and difficulty in sealing the lubricant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] like figure 1 As shown, the device is installed on the hydraulic press, the lower anvil 11 is fixedly connected with the workbench, and the upper anvil 4 is fixedly connected with the movable beam. When the hydraulic press is started, the movable crossbeam drives the upper anvil 11 and the upper hammer head 5 to apply downward pressure, and drives the left and right double toggle mechanisms to push the left and right sliders 6, 9 and the left and right hammer heads 7, 8 to extrude and forge toward the center of the billet. , forming four hammerheads up, down, left, and right to simultaneously extrude and forge toward the center of the billet. The billet can only be deformed in the axial direction due to the effect of extrusion forging, and then the movable beam is lifted upwards to drive the upper anvil and the upper hammer to be lifted upwards. The left and right side sliders and side hammer heads are pulled apart by the left and right double toggle mechanisms, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com