Ultrasonic inner sheet manufacturing machine

A technology of ultrasonic wave and manufacturing machine, which is applied in the fields of atlas and printing, etc. It can solve the problems of low qualified rate of finished products, easy deformation, high energy consumption, etc., and achieve the effects of stable quality, beautiful products, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

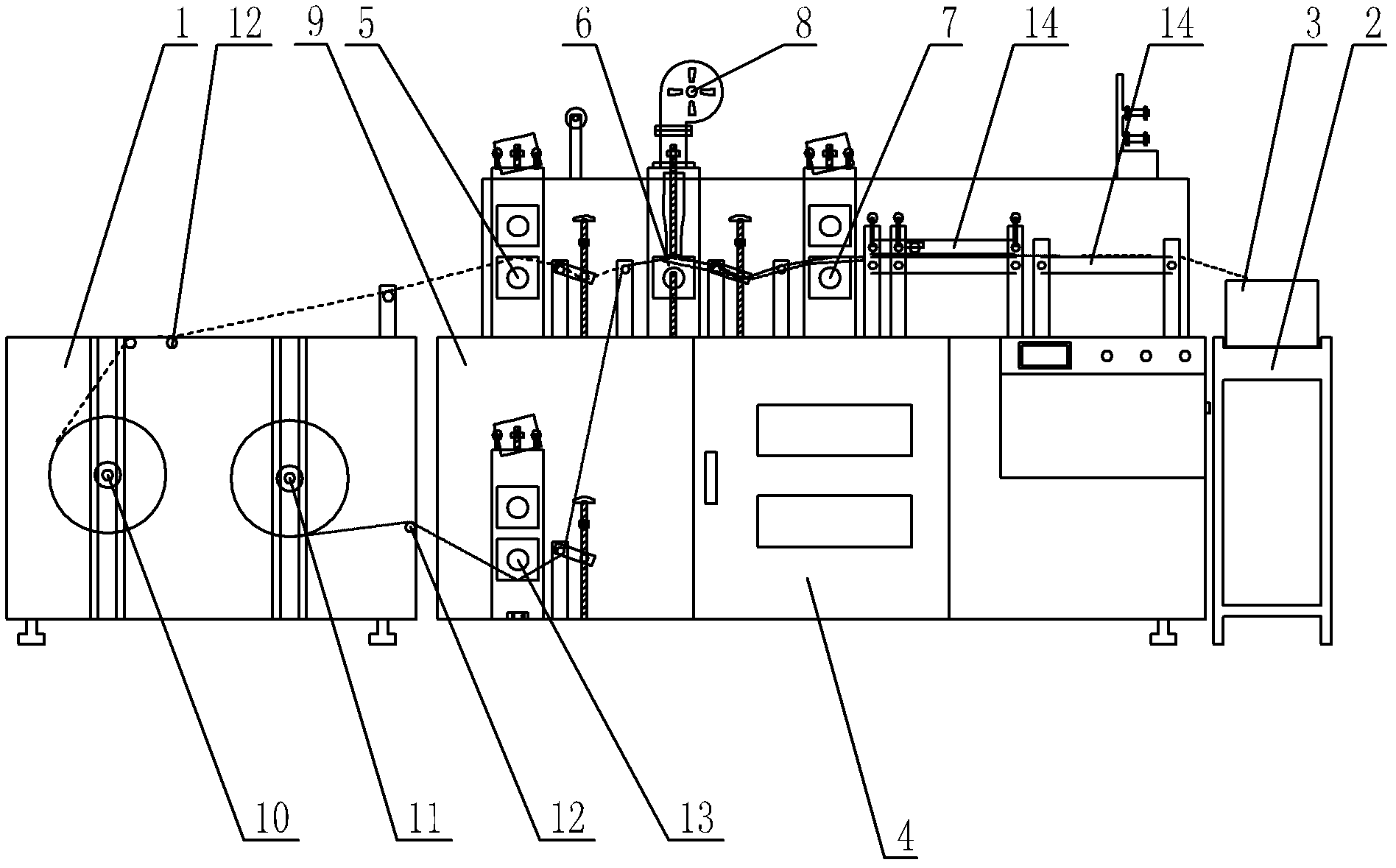

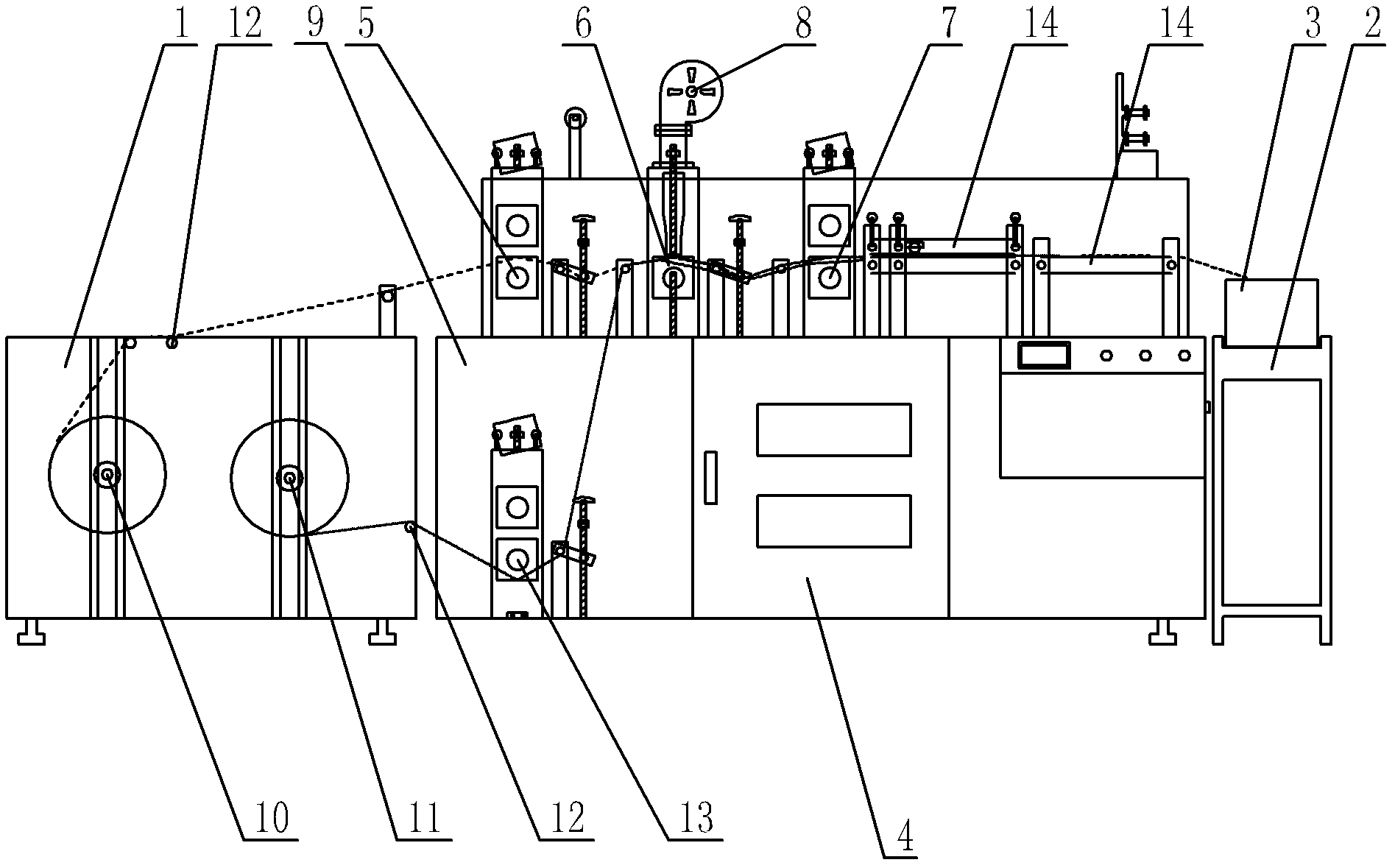

[0010] The present invention will be further described below in conjunction with specific drawings.

[0011] As shown in the figure: the ultrasonic inner page manufacturing machine includes a feeding mechanism 1, a finished product receiving and conveying table 2, a receiving box 3, an ultrasonic chassis 4, the first opening inner knife mold 5, an ultrasonic welding mold 6, a finished product outer knife mold 7, and cooling Fan 8, working platform 9, first feeding roller 10, second feeding roller 11, material breaking monitor 12, second opening inner knife mold 13, conveyor belt 14, etc.

[0012] The present invention includes a feeding mechanism 1, a working platform 9 and a finished product receiving and conveying platform 2. The feeding mechanism 1 includes a first feeding drum 10, a second feeding drum 11 and a material breaking monitor 12. On the working platform 9, the first opening inner knife mold 5, the ultrasonic welding mold 6 and the finished outer knife mold 7 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com