A crane frame

A frame and crane technology, which is applied in the field of new crane frames, can solve problems such as hidden dangers of safety and easy deformation in collision, and achieve the effects of preventing deformation, increasing the space of the frame, and strengthening the structure of the fuel tank.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

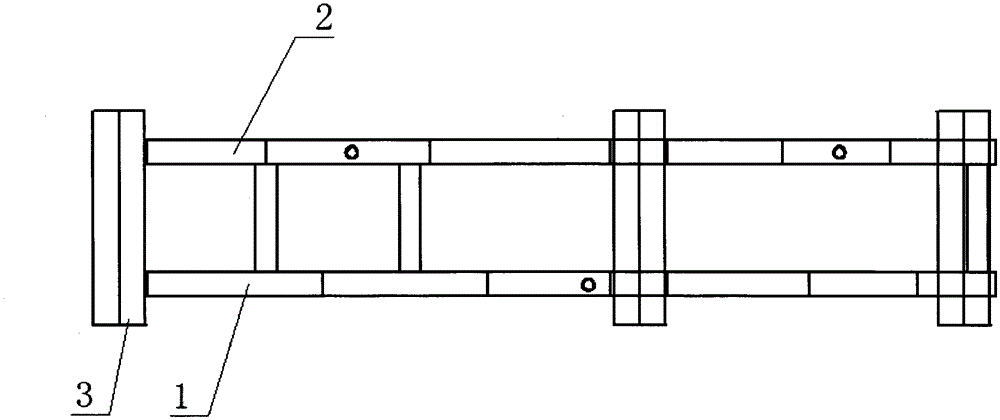

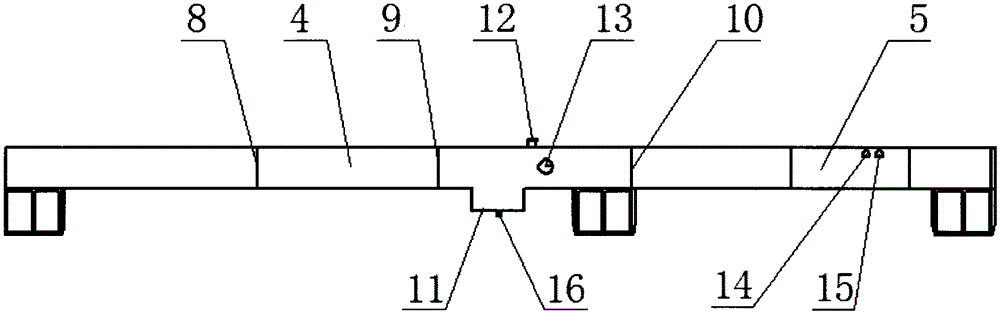

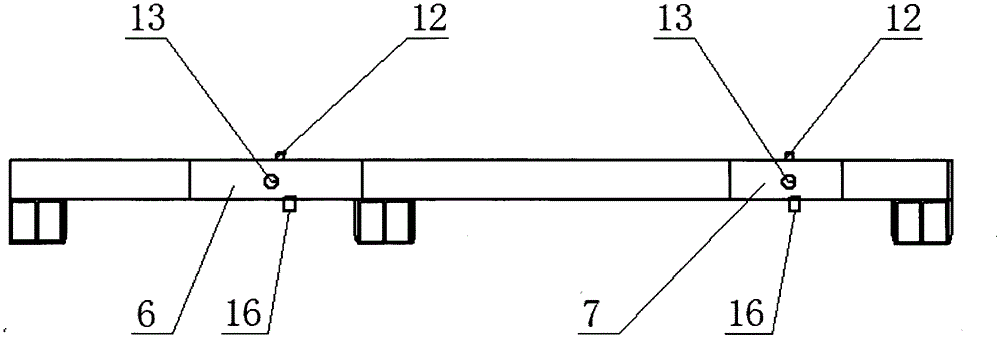

[0013] Such as figure 1 , figure 2 , image 3 Shown, a kind of crane frame, comprises girder and outrigger rod steel sleeve 3, and girder A1 of vehicle frame is provided with fuel tank 4 and gas tank 5, and girder B2 is provided with whole vehicle hydraulic oil tank 6 and steering gear booster fuel tank 7; The fuel tank 4 part of the girder A1 is provided with three afterburner support plates 8, 9, 10, and there is a round hole at the bottom of the middle afterburner support plate 9, and a protruding box body 11 is provided at the bottom of the fuel tank 4, protruding from the box body There is an oil outlet pipe 16 at the bottom, and a fuel nozzle 12 and an oil quantity indicator 13 are arranged outside the fuel tank 4; an air inlet 14 and an air outlet 15 are arranged outside the air tank 5; the vehicle hydraulic oil tank 6 on the beam B2 and the steering gear assist The fuel tank 7 is respectively provided with a fuel nozzle 12, an oil outlet pipe 16 and an oil level ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com