Rapid dismounting type supporting structure for coiled paper roll

A support structure, disassembly technology, applied in the field of support structure, can solve the problems of long time consumption of wire rod paper, affecting packaging efficiency, excessive release of packaging paper, etc., so as to improve replacement efficiency, avoid excessive release, and ensure packaging effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing.

[0034] In order to better show the structure of each part, some elements that cover other parts, such as handles and positioning tubes, are omitted from some figures.

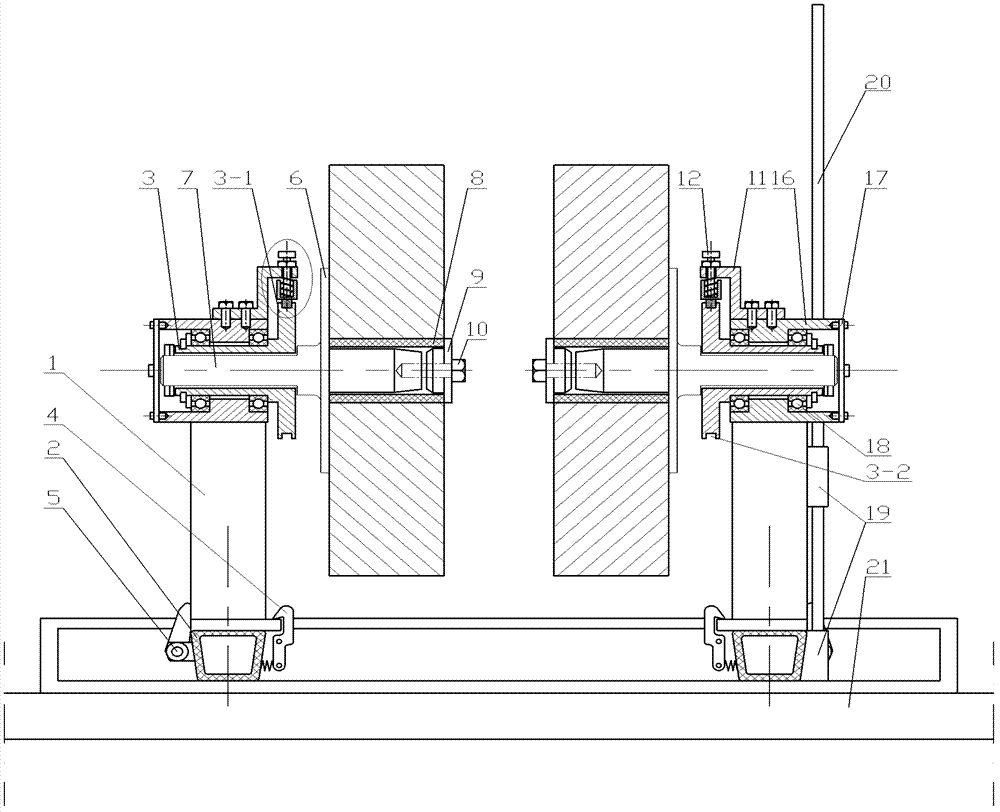

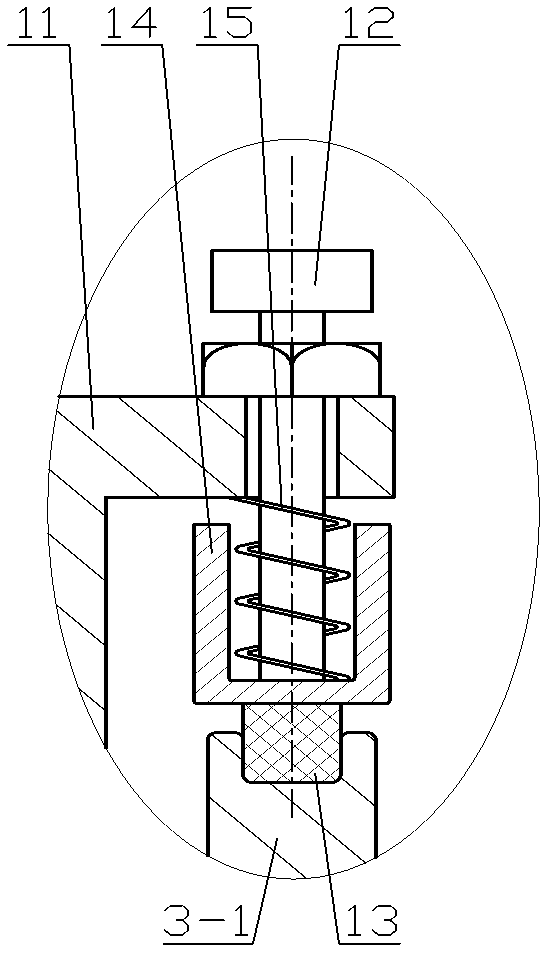

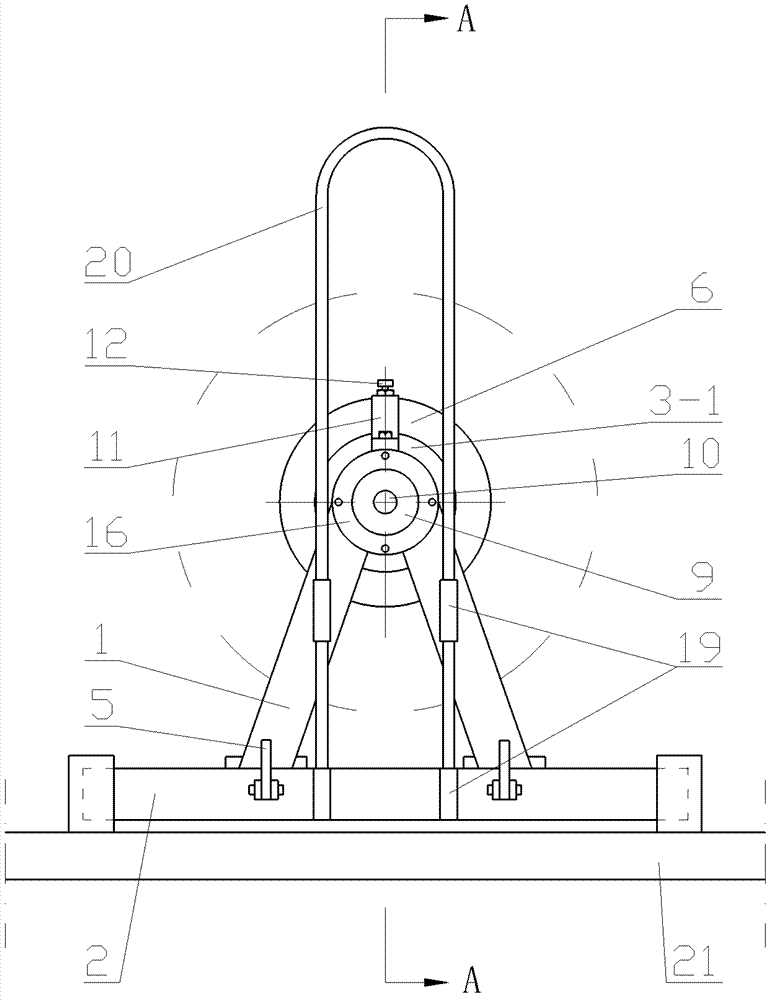

[0035] Figure 1-6 Among them, a vertical bracket 1 is arranged on the horizontal base 2, and one side of the bottom of the bracket 1 is hinged on the horizontal base 2 through a pair of hinges 5, and the side and the horizontal base 2 are locked by a self-locking buckle 4, and the bracket 1 can be Flip around the hinge 5, from the vertical state to the horizontal state, respectively arrange the positioning tube 19 on the bracket 1 and the horizontal base 2 inside each pair of hinges 5, the lower end of the elongated handle 20 moves through the inner hole of the positioning tube 19, and the handle 20 can be inserted / extracted from the positioning tube 19.

[0036] The top of the bracket 1 is fixed with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com