Transporting device for machining workpiece

A technology for transportation devices and workpieces, which is applied in the directions of manual conveying devices, transportation and packaging, mechanical conveyors, etc., can solve the problem of high transfer costs of machined workpieces, reduce the cost of mechanical equipment and power, and overcome the problems of large horse-drawn carts, The effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

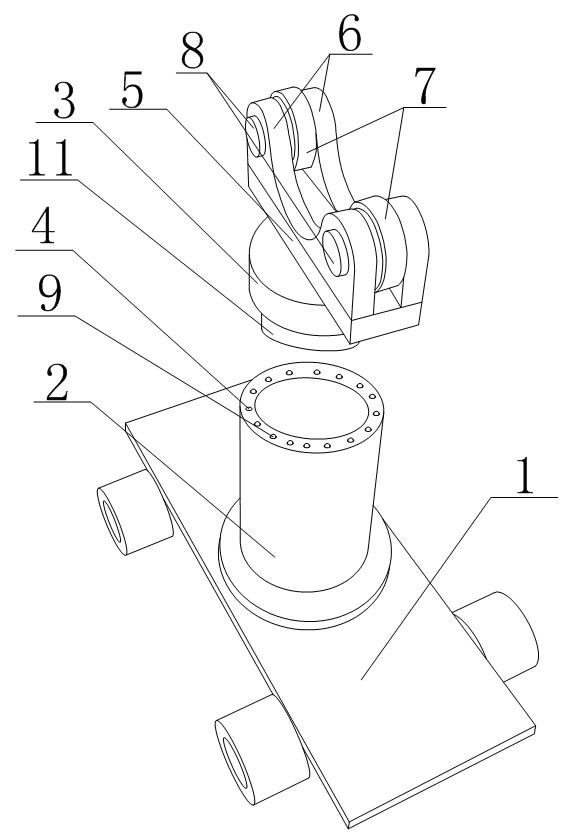

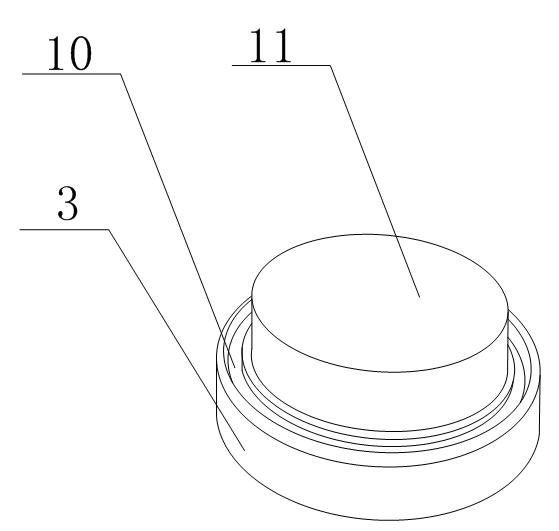

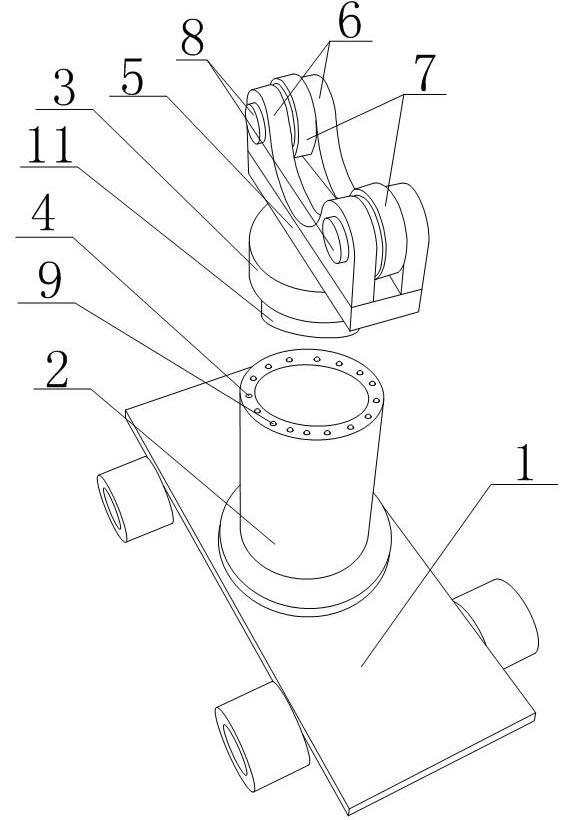

[0019] Such as figure 1 As shown, a transport device for machining workpieces of the present invention includes a transport vehicle 1, the transport vehicle includes a vehicle body and wheels, a support column 2 is arranged on the vehicle body, the support column 2 is a hollow cylinder, and the support column 2 Several circular grooves are arranged on the side wall of the top, and the grooves surround the top of the support column 2 to form a ring shape, and balls 9 are placed in the grooves; The lower part is provided with a guide column 11 matching the inner diameter of the support column 2, and an annular groove 10 surrounding the guide column 11 is provided on the rotating platform 3. The annular groove 10 is located on the ball 9, and the width of the annular groove 10 is the same as that of the ball. 9 matches the diameter, the sum of the depth of the annular groove 10 and the depth of the groove where the ball 9 is placed is less than or equal to the diameter of the bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com