Novel diesel engine cylinder cover

A cylinder head and diesel engine technology, applied in the direction of cylinder heads, cylinders, mechanical equipment, etc., can solve the problems of inability to meet the requirements of high power density diesel engines, poor reliability, large volume, etc., to improve water flow speed and cooling effect, light weight , good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

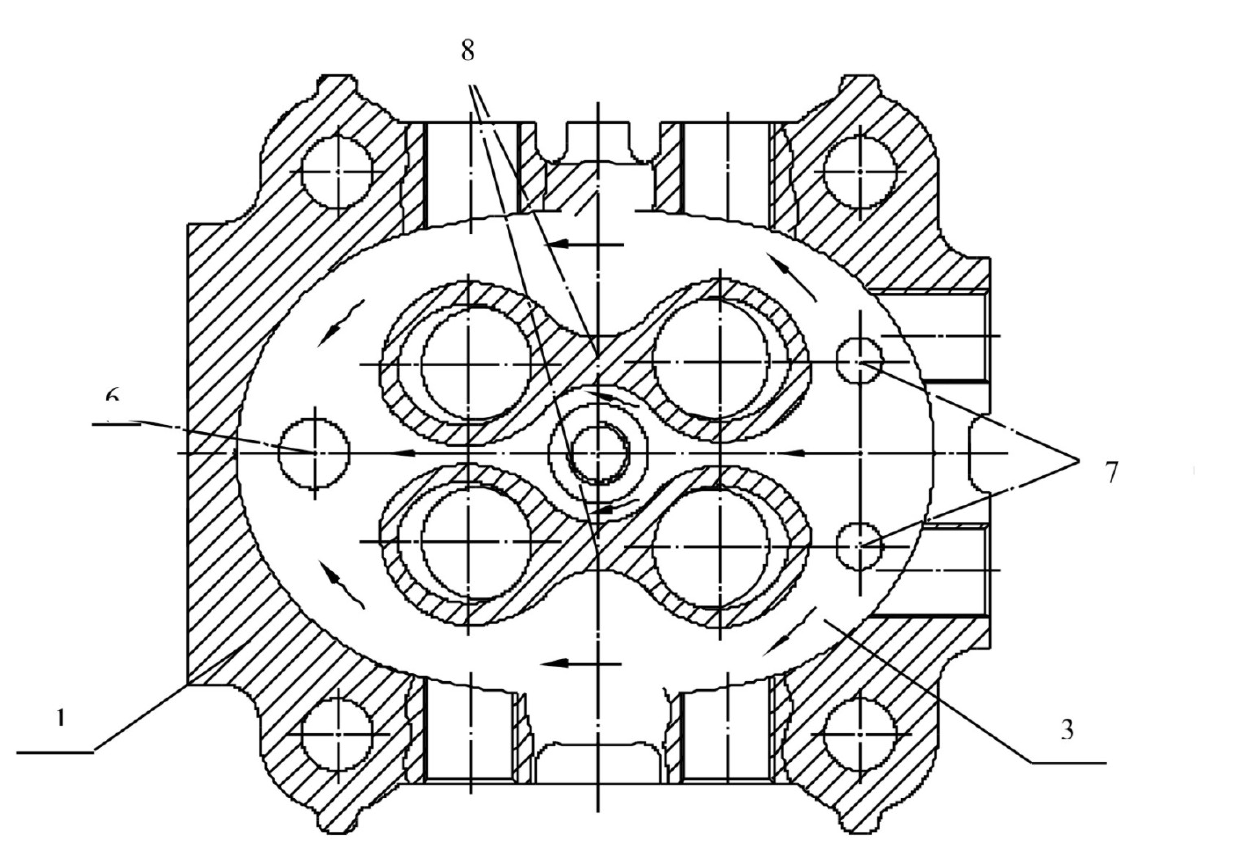

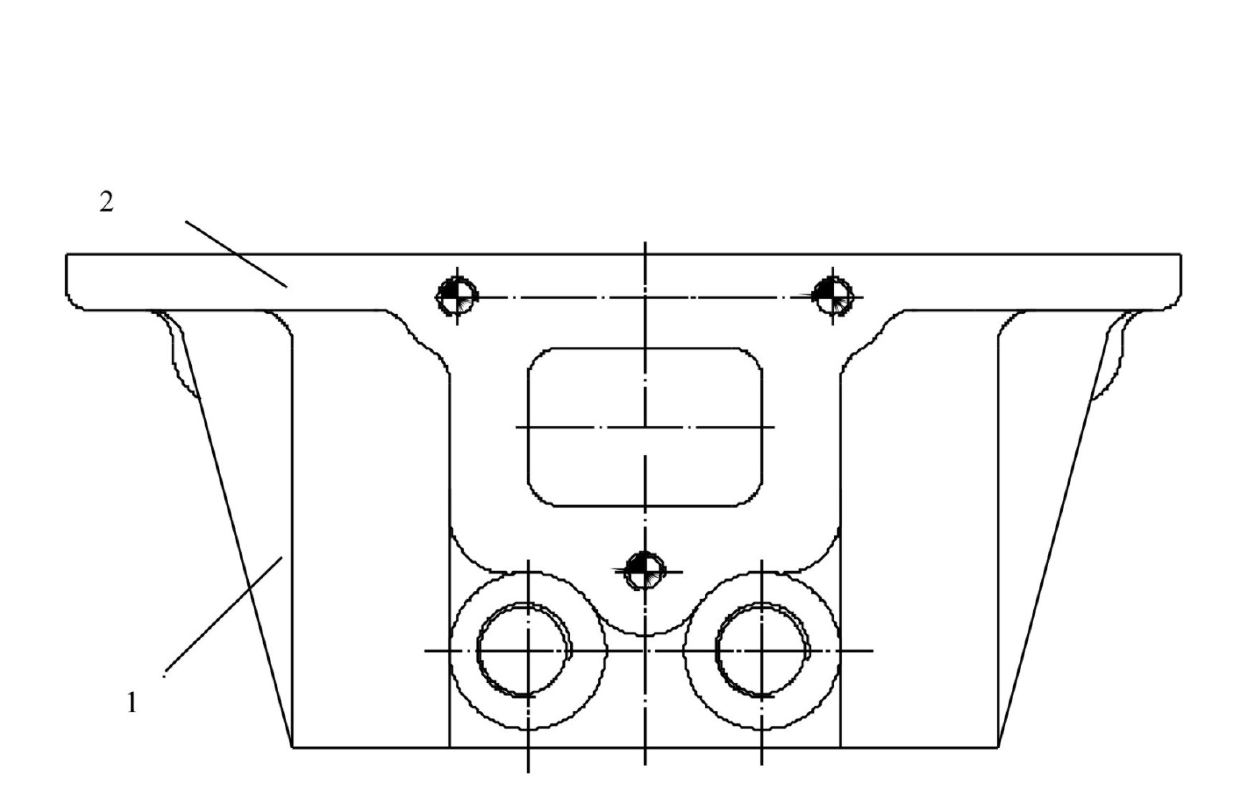

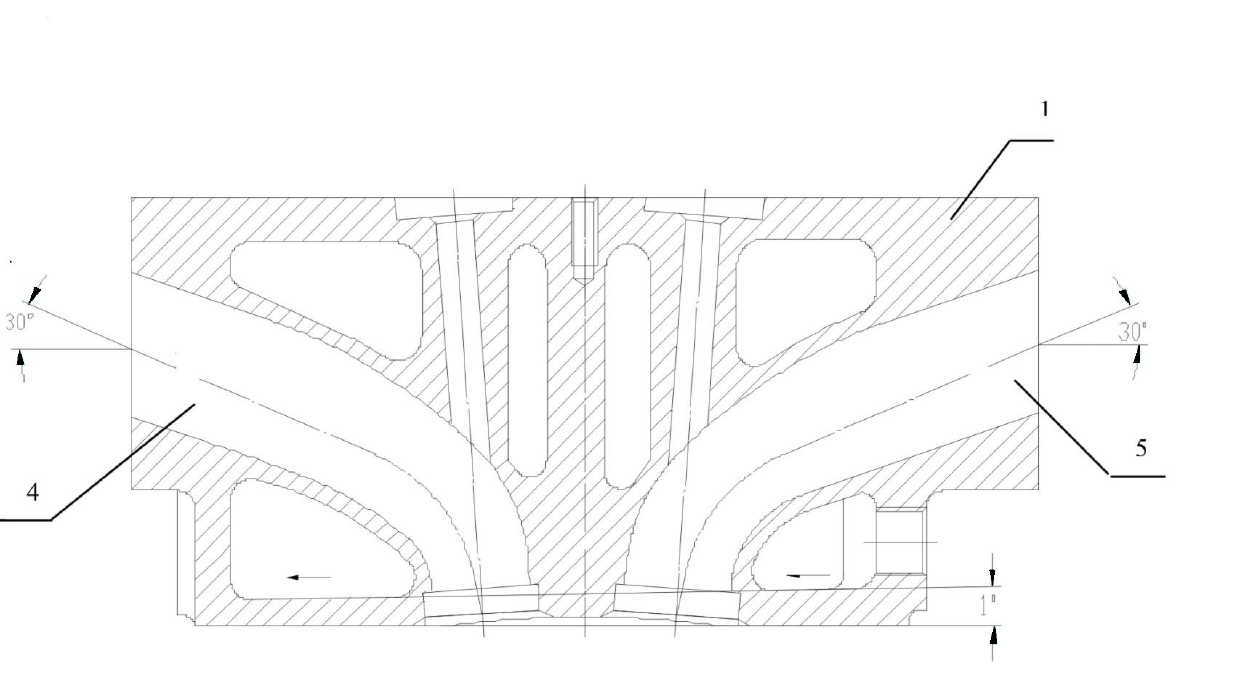

[0013] A new type of diesel engine cylinder head, which includes a cylinder head body 1, a gas distribution top plate 2, such as figure 1 , figure 2 , image 3 As shown, the gas distribution top plate 2 is arranged on the cylinder head body 1, and its shape is a trapezoidal cube, which not only ensures the arrangement of the gas distribution mechanism in the form of oblique valves, but also effectively reduces the volume and quality of the cylinder head. The water cavity 3 is arranged in the cylinder head body 1, and the bearing column 8 is arranged in the water cavity 3. The water cavity is an inclined water cavity without a middle partition, and the air inlet channel 4 and the exhaust channel are arranged on the cylinder head body. 5. The cylinder head adopts a slanted four-valve structure. The intake port 4 and the exhaust port 5 are low-resistance straight air channels that are raised 30° upwards and connected in parallel, which reduces resistance, improves the flow coef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com