Device used for filtering, dehumidificating and mixing smoke

A flue gas and mixing chamber technology, which is used in the field of flue gas filtration, dehumidification and mixing devices, can solve the problems of huge sampling and analysis workload, long sampling duration, and large pipeline section.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

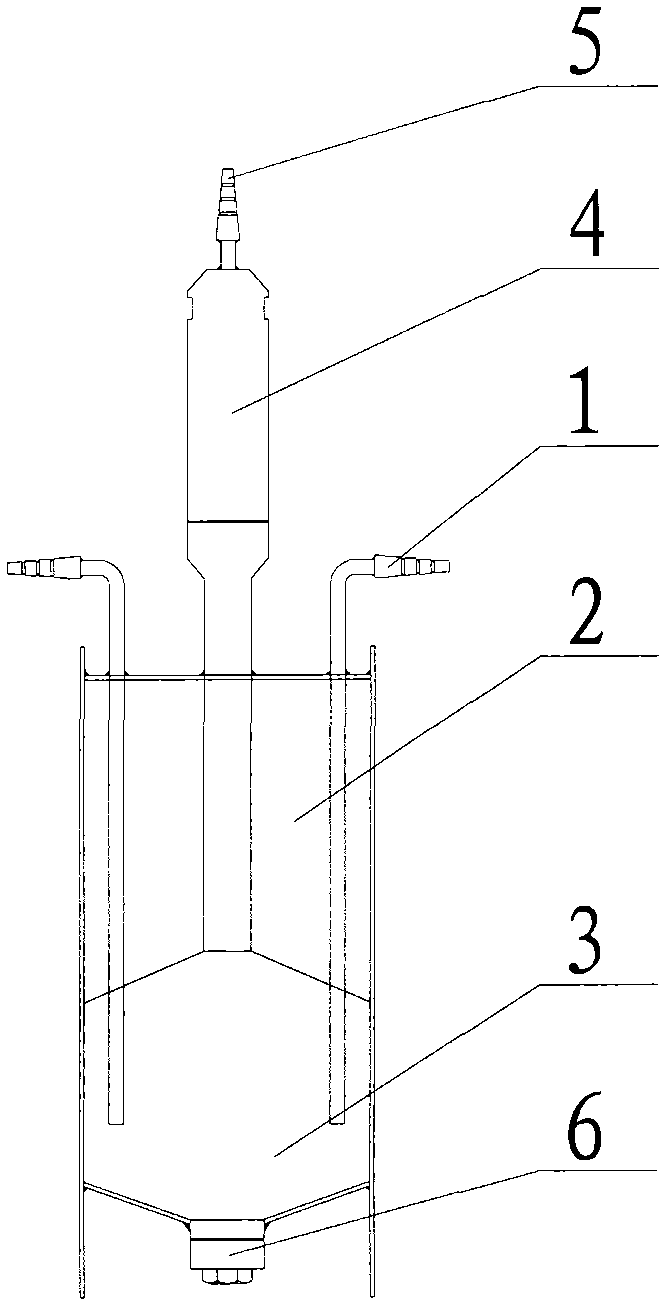

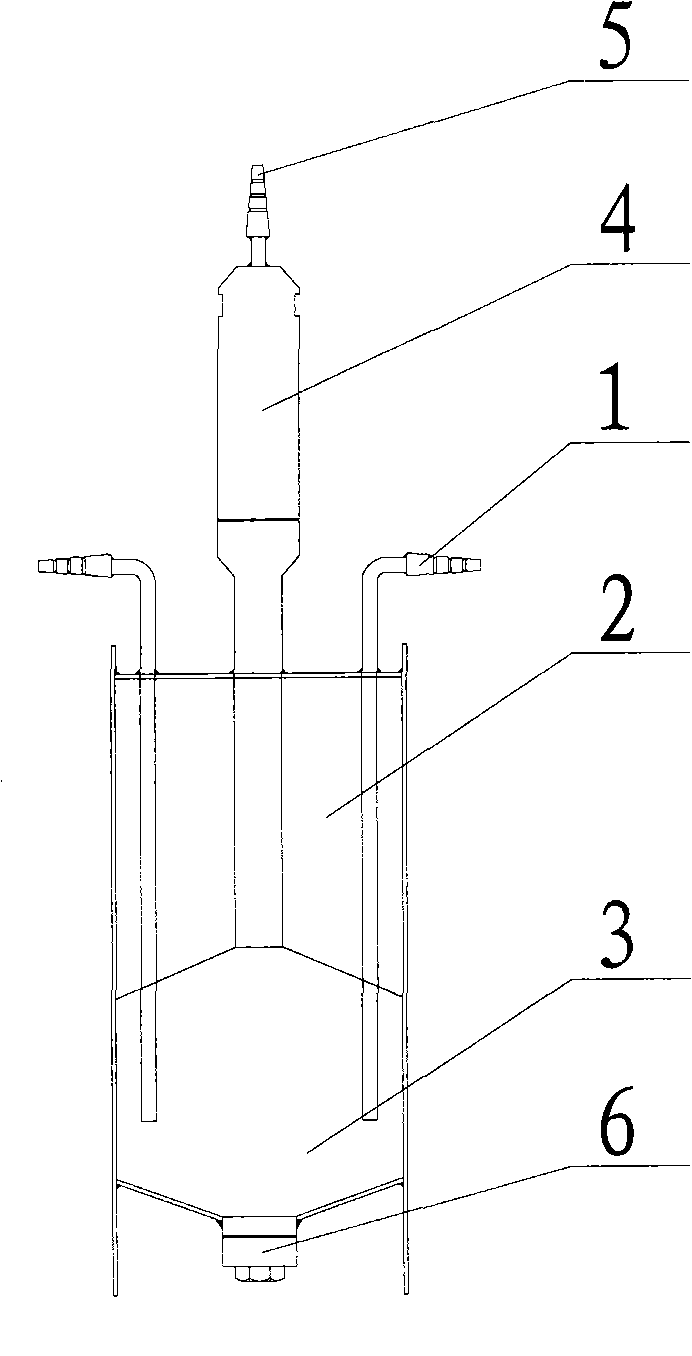

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0011] like figure 1 As shown, the device is composed of the following six main parts: flue gas introduction pipe 1, dehumidification chamber 2, mixing chamber 3, filter chamber 4, flue gas outlet pipe 5, and ash discharge port 6. The overall device is in the shape of a cylinder, and the device is divided into the upper part as the dehumidification chamber 2; the lower part as the mixing chamber 3, and a water collecting partition is set between the two. A flue gas introduction pipe 1 and a flue gas extraction pipe 5 are installed in the mixing chamber 3 to pass through the dehumidification chamber 2 and lead to the outside. The flue gas introduction pipe 1 is arranged circularly along the circumference of the cylinder, and the flue gas extraction pipe 5 is located in the center of the cylinder. The lower part of the flue gas outlet pipe 5 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com