Stator of vertical shaft aerogenerator

A wind turbine, vertical axis technology, applied in the shape/pattern/structure of winding conductors, magnetic circuit shape/pattern/structure, magnetic circuit static parts, etc., can solve the waste of resources, low utilization efficiency, wind turbines The problem of insufficient machining precision between the magnet and the coil can improve the power generation efficiency and save the material consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

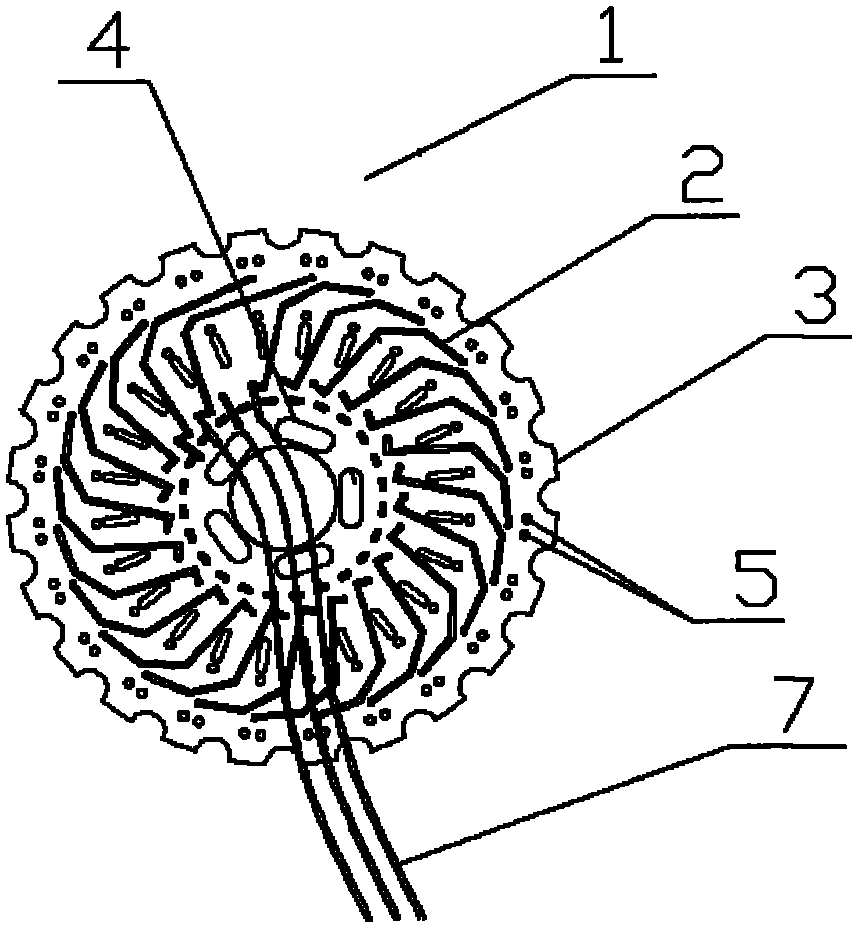

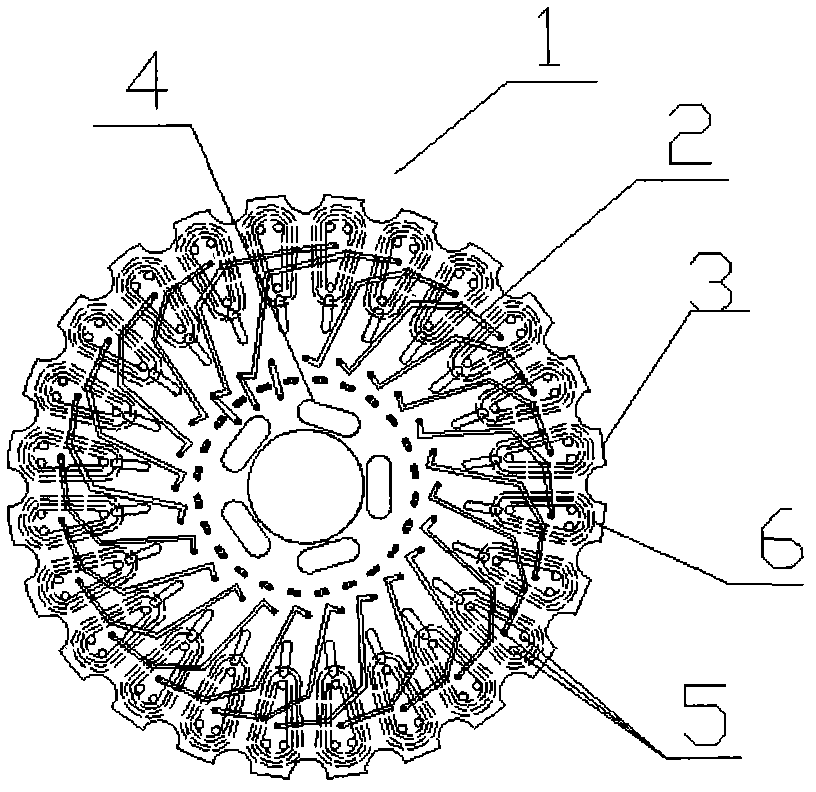

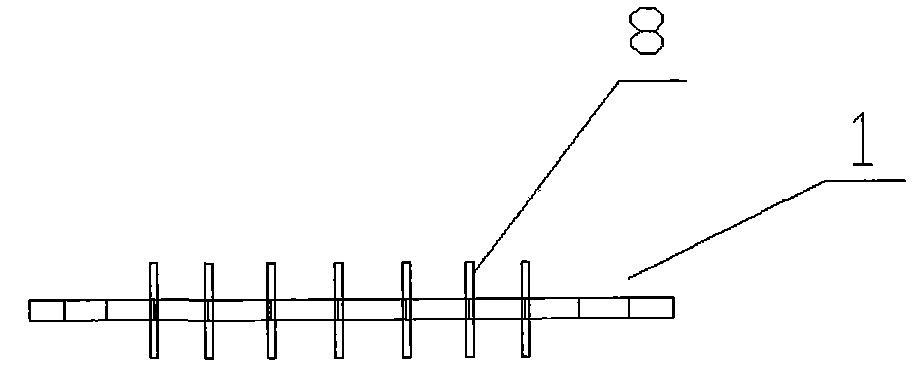

[0025] The stator 1 of the vertical axis wind power generator according to the present invention includes a plurality of coils 6 and a circuit board 9 inserted with the stator shaft 10, the coils 6 are distributed on the front and back sides of the circuit board 9, and the Corresponding coils 6 on the front and back sides are connected by double-sided wires 2, and the plurality of coils 6 are electrically connected in an angular shape. The stator shaft 10 has a central shaft hole, and three lead wires 7 of the coil 6 welded on the circuit board 9 pass through the central shaft hole so as to output power; the coil 6, the circuit board 9, and the stator shaft 10 are The resin cures as one. In the stator of the vertical axis wind power generator according to the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com