TFT array inspection method and TFT array inspection apparatus

An inspection method and array technology, applied in the direction of measuring devices, identification devices, electronic circuit testing, etc., to achieve the effect of improving the defect detection rate, eliminating the influence of pixel voltage, and prolonging the voltage holding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

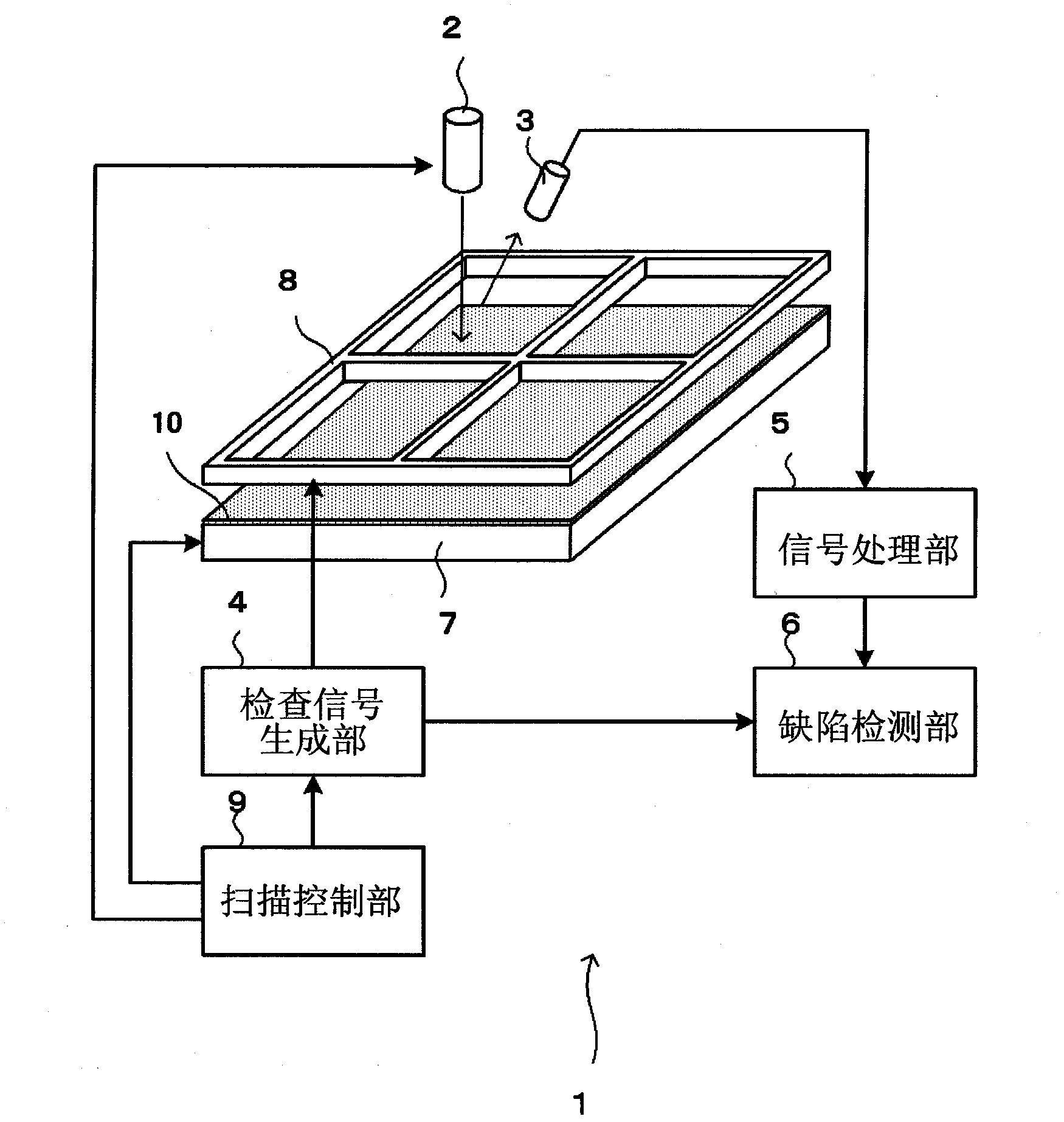

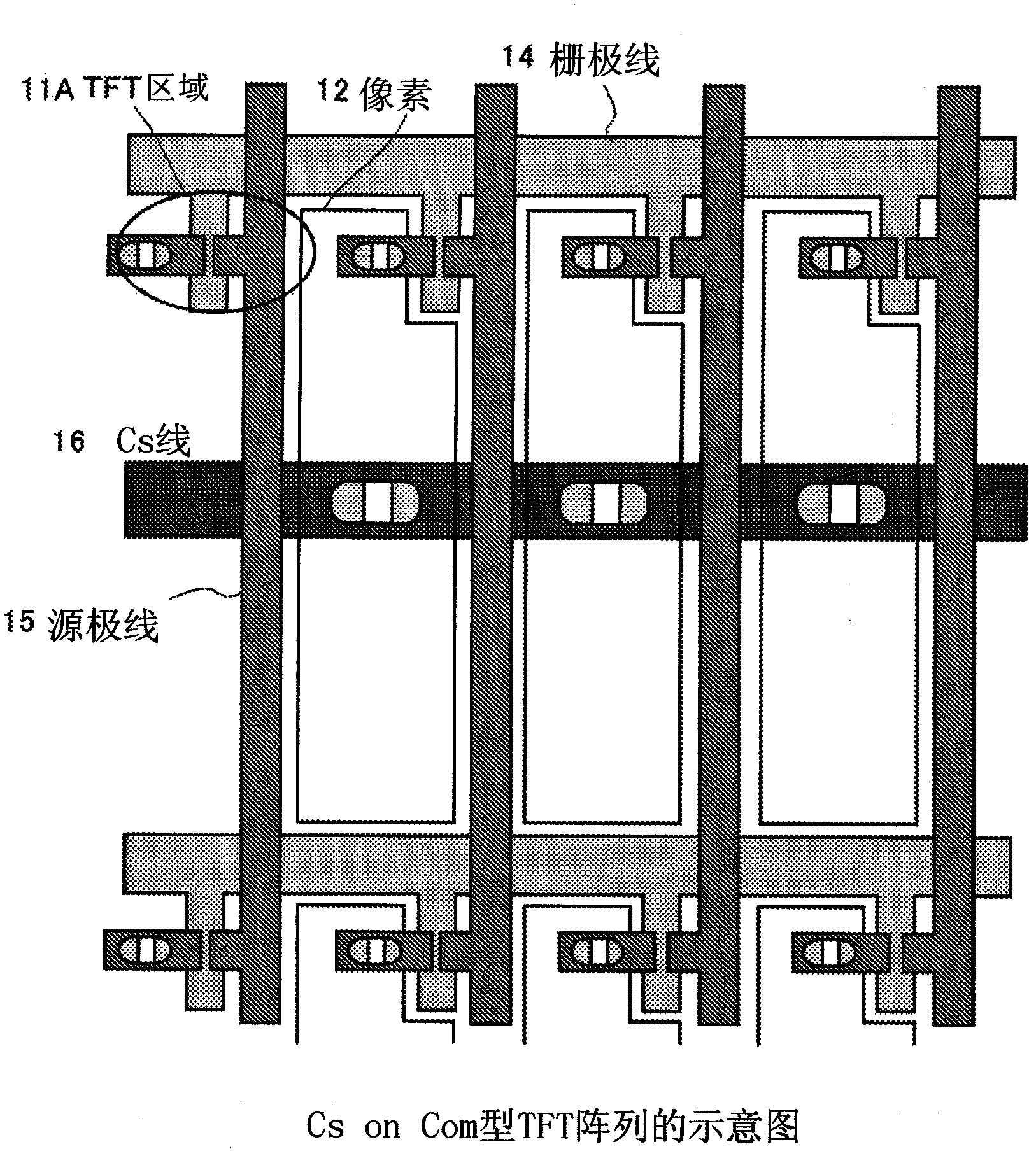

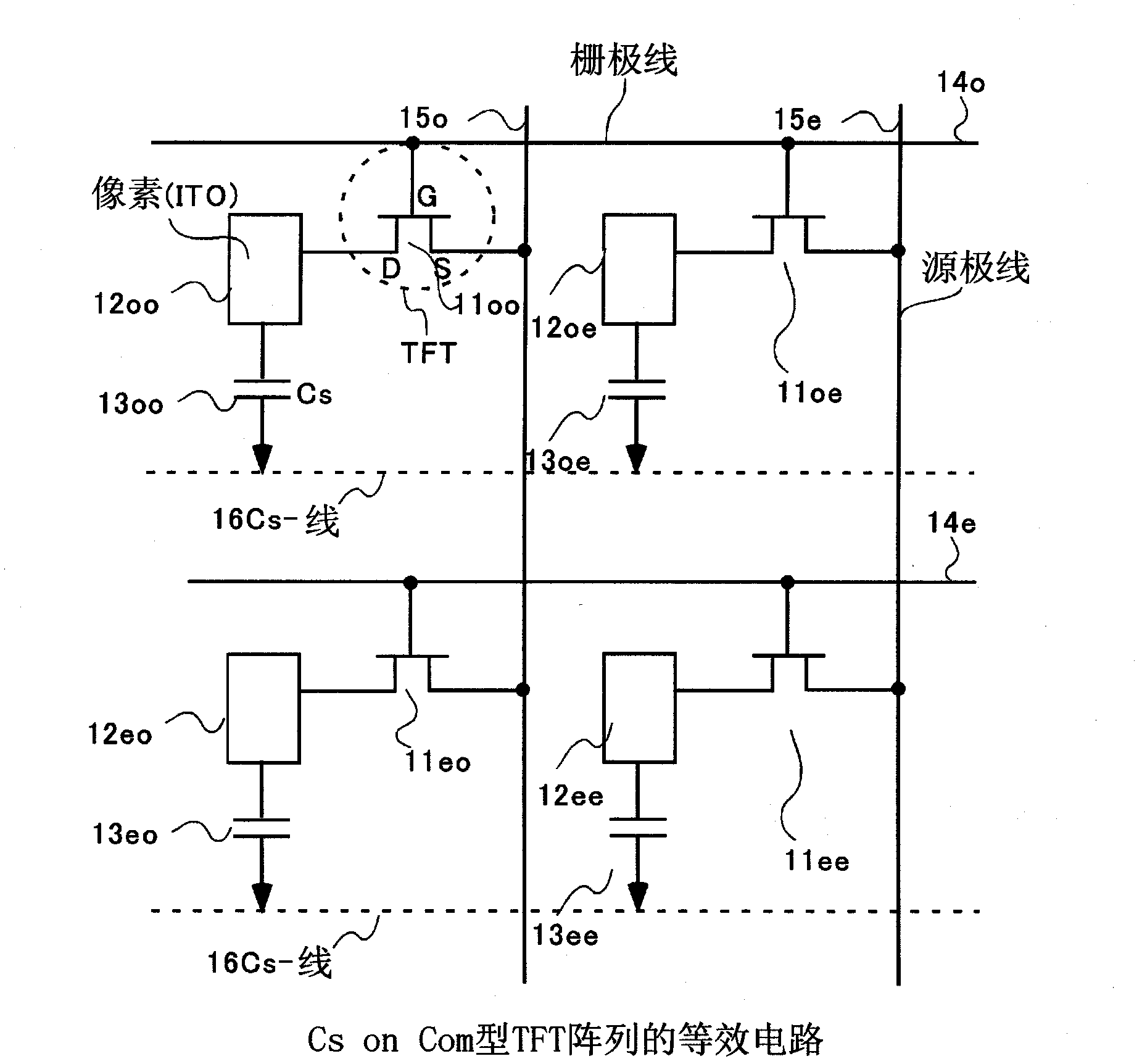

[0080] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. Next, use figure 1 A structural example of a TFT substrate inspection device of the present invention will be described, using Figure 7 to Figure 18 The inspection method of the TFT substrate of the present invention will be described. Figure 7 to Figure 9 It is a diagram for explaining a first inspection method in which one gate period is set as a positive voltage holding time in a Cs on Com type TFT array in which pixels are connected to a common line. Figure 10 to Figure 12 It is a diagram for explaining the second inspection method in which one gate period is set as a negative voltage holding time in a Cs on Com type TFT array in which pixels are connected to a common line. Figure 13 to Figure 15 It is a diagram for explaining a third inspection method in which one gate period is set as a positive voltage holding time in a Cs on Gate type TFT array in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com