Motor with transmission function

A technology of electric motors and functions, applied in the field of electric motors, can solve the problems of poor vehicle performance, high speed, low efficiency, etc., and achieve the effect of good energy efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

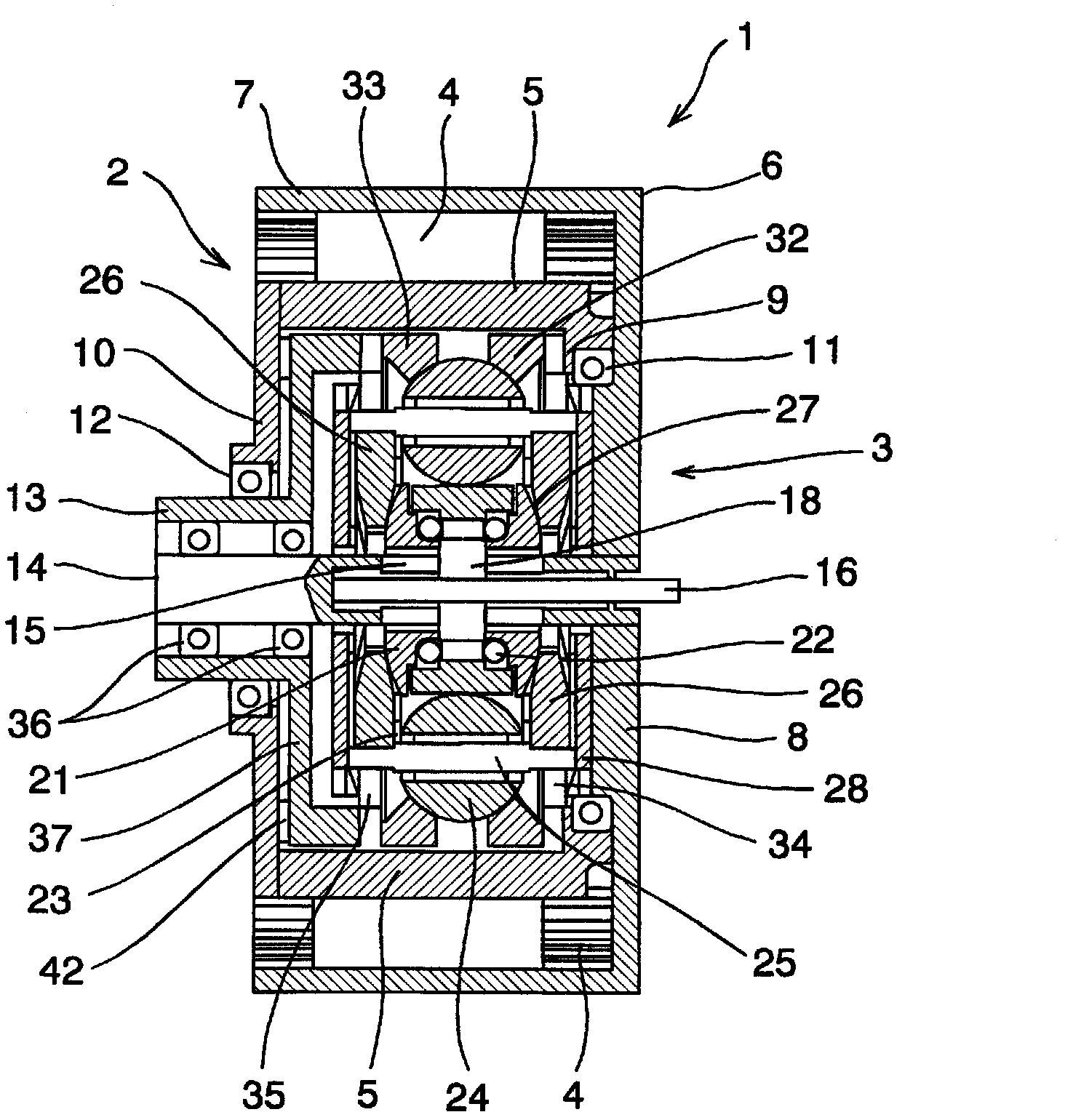

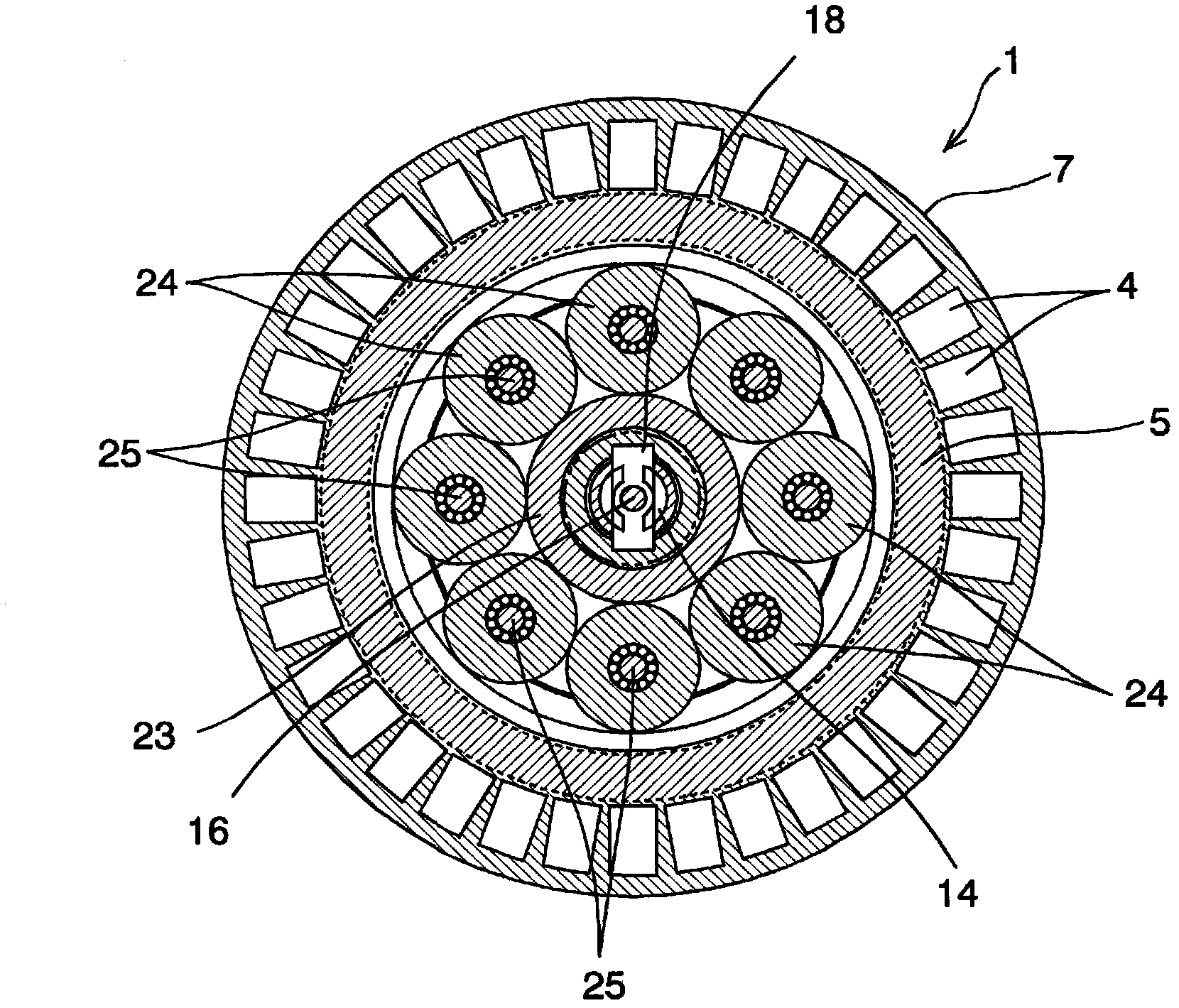

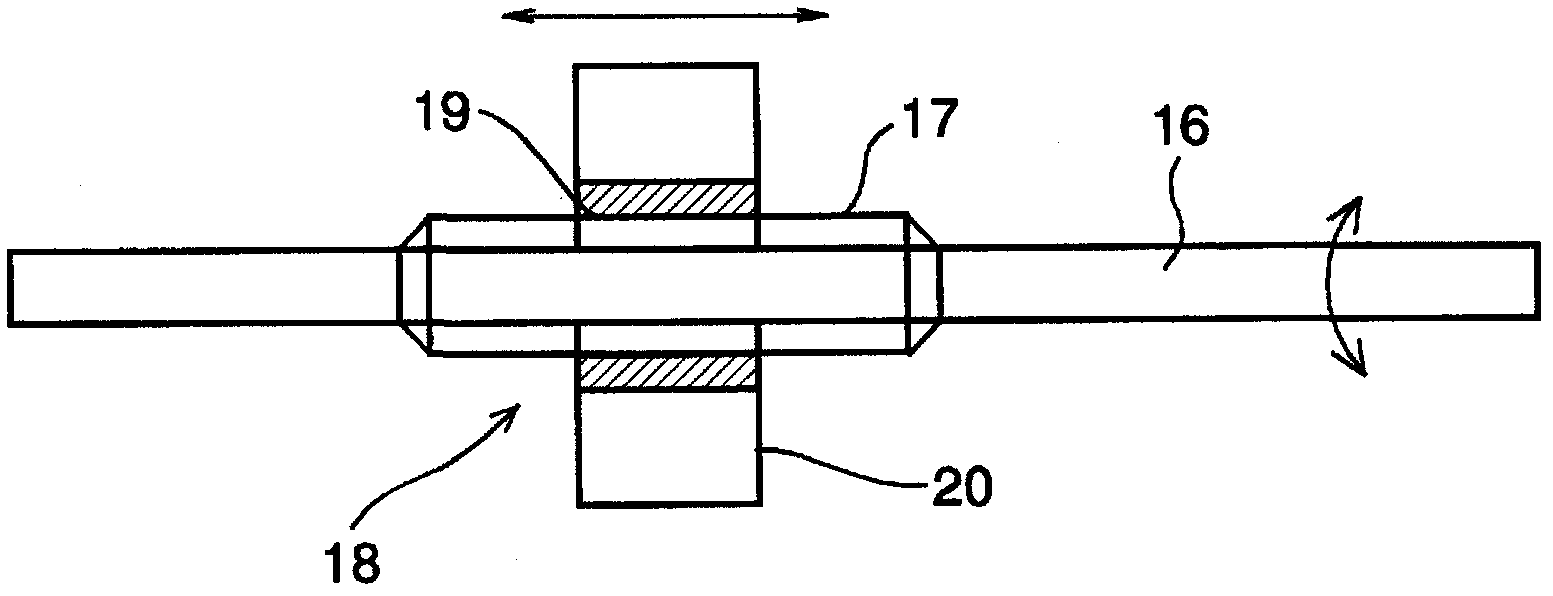

[0035] Next, the present invention will be described more specifically. figure 1 and figure 2 This shows an example of the electric motor 1 according to the present invention, and the electric motor 1 shown here is configured such that the continuously variable transmission mechanism 3 is disposed on the inner peripheral portion of the electric motor unit 2 . When describing the structure of the motor unit 2 , the motor unit 2 includes a stator coil 4 and a rotor 5 disposed on the inner peripheral side of the stator coil 4 . The stator coil 4 is configured by arranging a plurality of coils wound around an iron core in a cylindrical shape, and is fixed to the inner peripheral surface of the cylindrical portion 7 of the outer casing 6 . The outer casing 6 is a cylindrical member having a bottom, and the plate-shaped portion opposite to the bottom is an end plate portion 8 , and the cylindrical portion 7 is integrated with the outer peripheral portion of the disk-shaped end pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com