ultrasonic transducer

An ultrasonic transducer and ultrasonic vibration technology, applied in ultrasonic/sonic/infrasonic diagnosis, ultrasonic diagnosis, infrasonic diagnosis, etc., can solve the deformation of the rear mass block, affect the stress distribution of the crystal pile, and the stress distribution of piezoelectric elements and electrodes. Uniformity and other issues to achieve large compression range, improve efficiency, and reduce heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The specific embodiments described here are only used to explain the present invention, and are not used to limit the protection scope of the present invention.

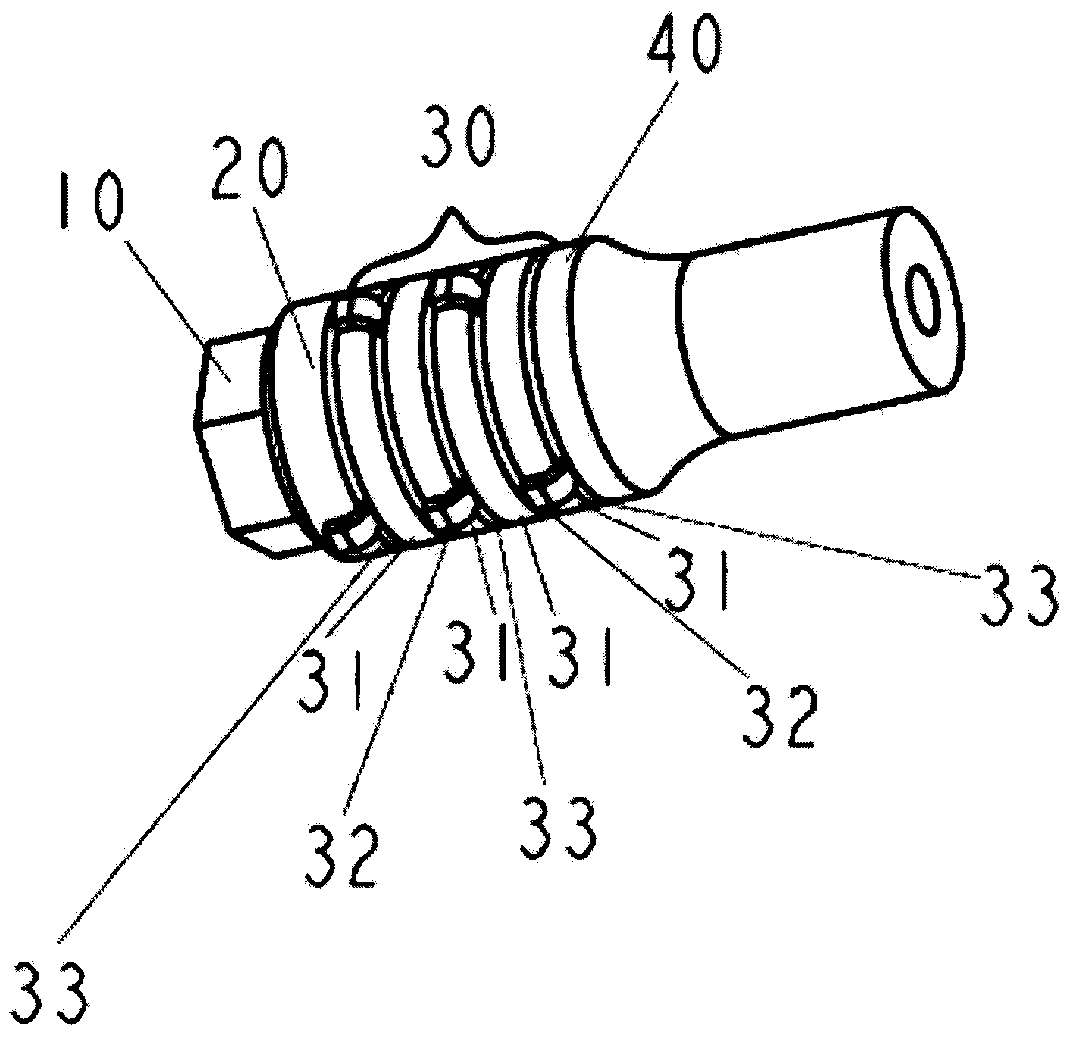

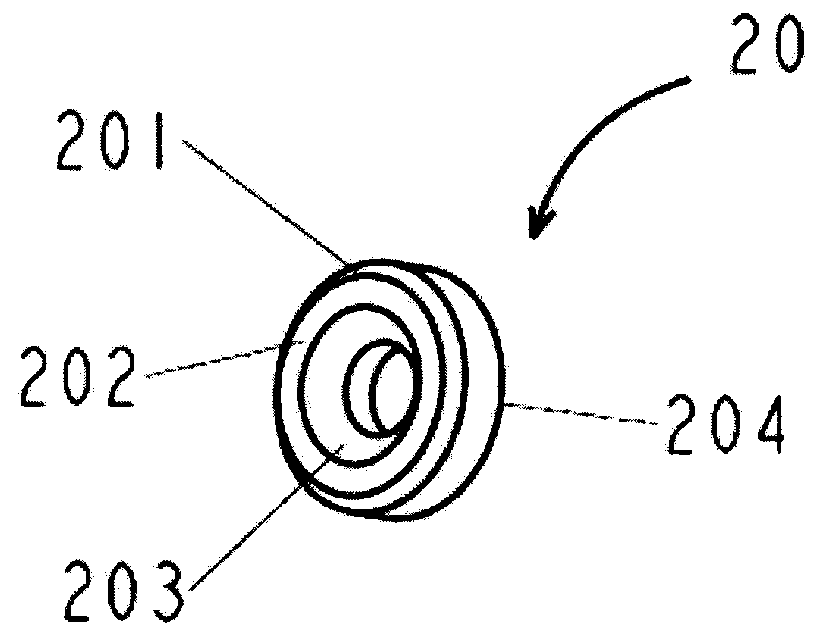

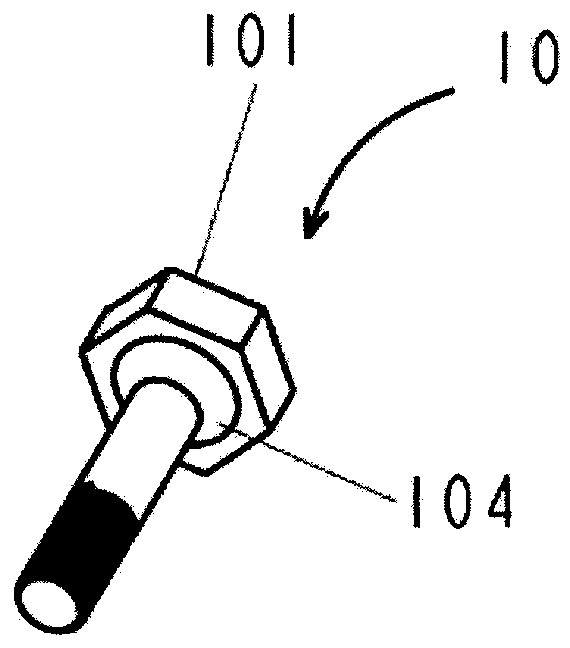

[0049] refer to image 3 A schematic diagram of an ultrasound transducer according to a specific embodiment of the invention is shown. The ultrasonic transducer of the present invention comprises: installation device 4, and installation device 4 is connected with a compressing device; Connection mode can be screw connection, also can adopt other connection modes such as spring connection, welding to replace; Crystal stack 3, be arranged on Between the installation device 4 and the compression device, the crystal stack 3 includes a plurality of electrodes stacked alternately with positive and negative electrodes, and a piezoelectric element 31 is arranged between two adjacent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com