Welding harmful gas emission device

A technology for discharging devices and harmful gases, applied in auxiliary devices, welding equipment, removing smoke and dust, etc., can solve the problems of affecting the operator's sight, the gas flow is not fixed, and welding cannot be performed at the same time, so as to achieve the effect of a good working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments, structures, and effects of the present invention will be described in detail below with reference to the accompanying drawings.

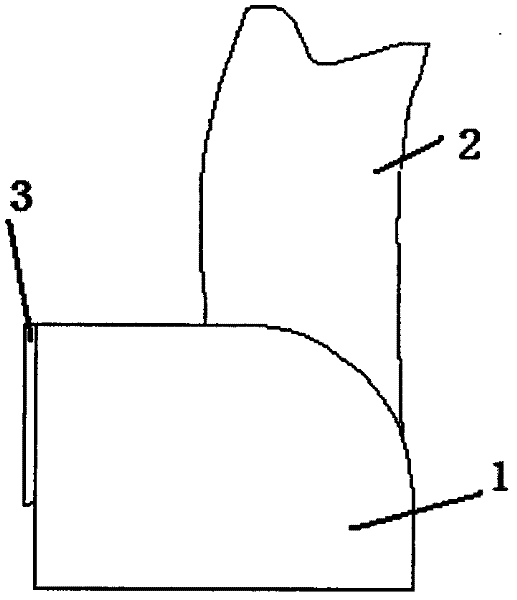

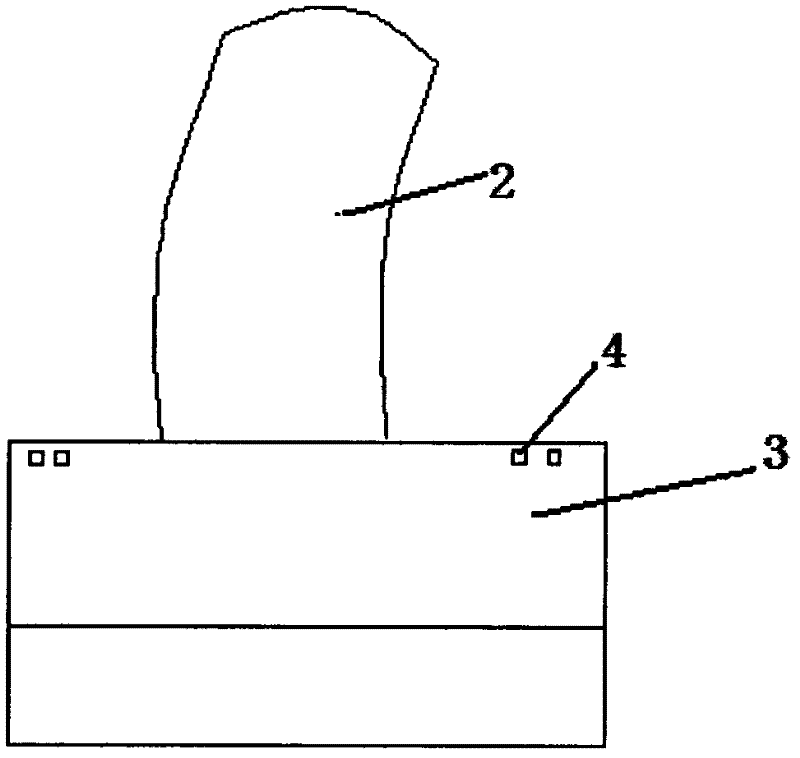

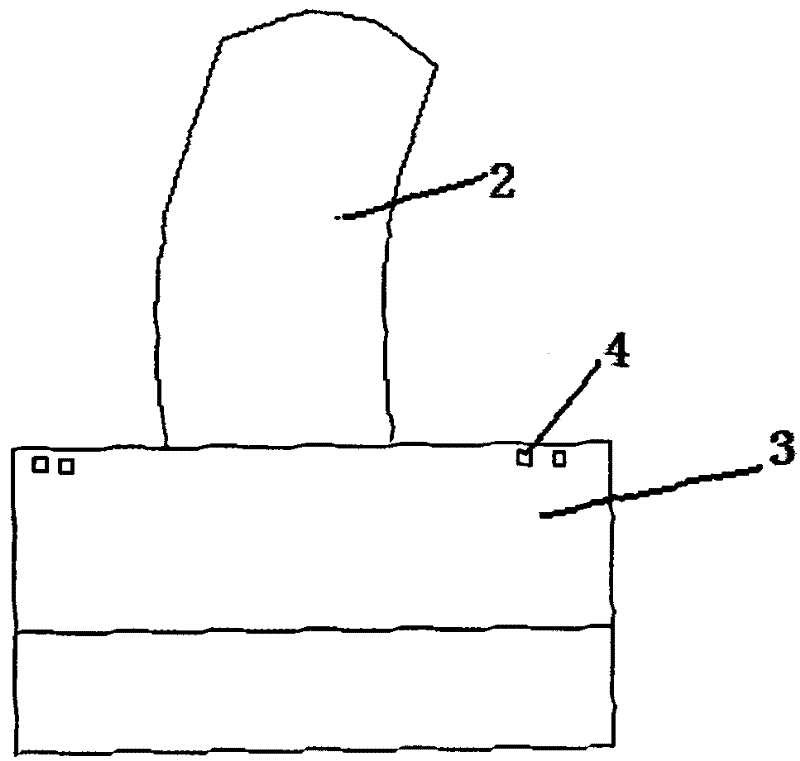

[0015] Such as figure 1 and figure 2 As shown, the baffle plate 3 of transparent material is connected with the upper edge of the opening side of the gas shield 1 through the hinge 4, wherein the lower edge of the baffle plate 3 has a certain distance from the lower edge of the opening side, which is convenient for welding. Put it into the gas mask 1 for welding. Before welding, turn up the baffle 3, put the products to be welded and welding tools into the gas hood 1, and then turn down the baffle 3 so that the gas generated during welding will not flow from the side of the opening. flow out. When welding, the exhaust fan is turned on, so that the harmful gas produced is exhausted through the exhaust pipe 2 installed on the top of the gas shield 1 by the exhaust fan. The gas cover 1 is arc-shaped, which is beneficial for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com