Heavy-duty self-driven omnidirectional wheel and design method thereof

An omnidirectional wheel, self-driven technology, applied in the direction of wheels, transportation and packaging, vehicle parts, etc., can solve the problems of low efficiency, large working space, large turning radius, etc., and achieve flexible and stable movement, strong bearing capacity, and flexible movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

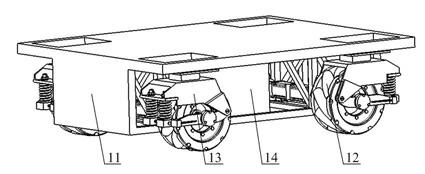

[0063] The following is a preferred embodiment of the omnidirectional mobile platform for transporting self-driven omnidirectional wheels and aircraft parts of the present invention in conjunction with the accompanying drawings of the description.

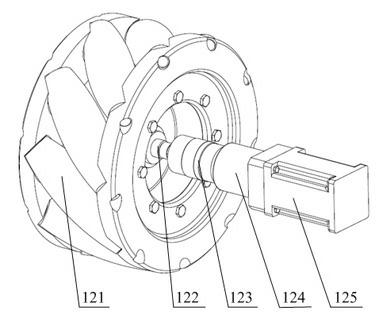

[0064] Such as figure 2 As shown, the self-driving omni wheel includes an omni wheel body 121 , a transmission shaft 122 , a coupling 123 , a reducer 124 and a motor 125 . The output shaft of the motor 125 is connected with the input end of the reducer 124, the output shaft of the reducer 124 is connected with the transmission shaft 122 through the coupling 123, the transmission shaft 122 is connected with the omnidirectional wheel body 121, and the omnidirectional wheel body is on the transmission shaft The axial position is fixed by the shaft shoulder and the nut.

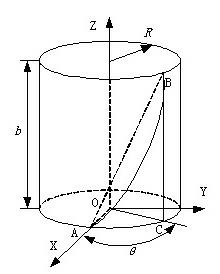

[0065] suppose image 3 The cylinder in is an omnidirectional wheel, and the coordinate system is established with the direction of the wheel axis as the Z axis. R ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com