Intelligent carrying mechanical jaw for electric vehicle parts

A technology of intelligent handling and electric vehicles, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low picking, handling and stacking efficiency, heavy wheel weight, dangerous safety accidents, etc., and achieves high grasping efficiency and high degree of automation. , the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

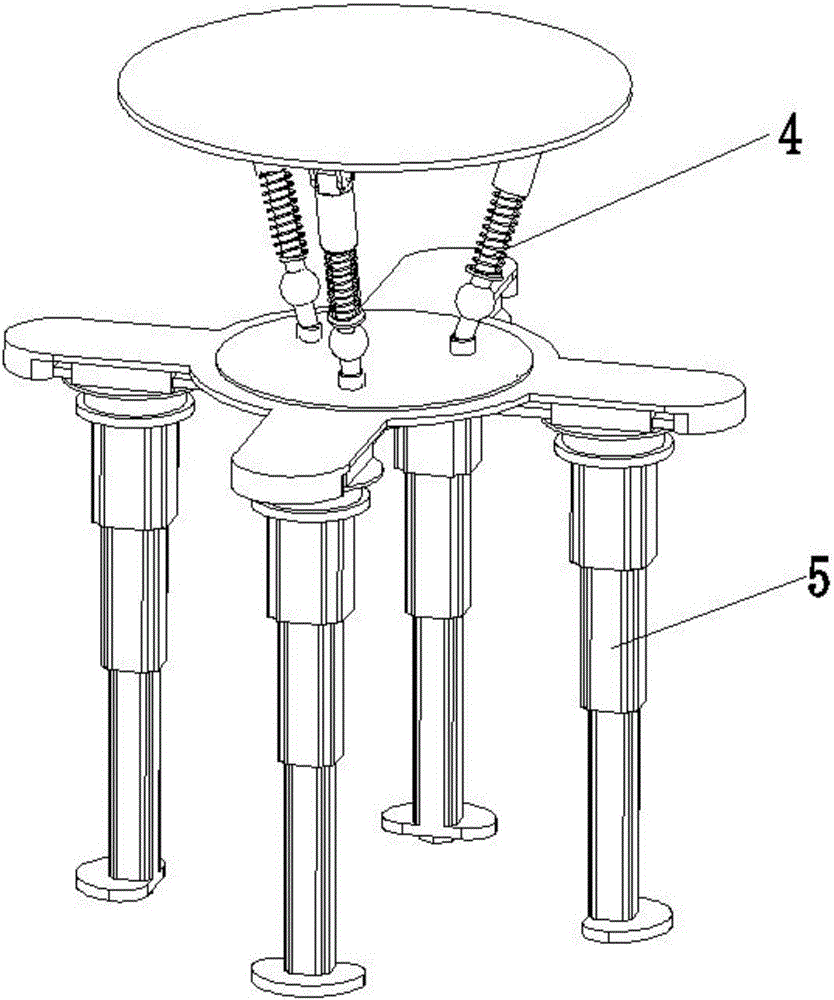

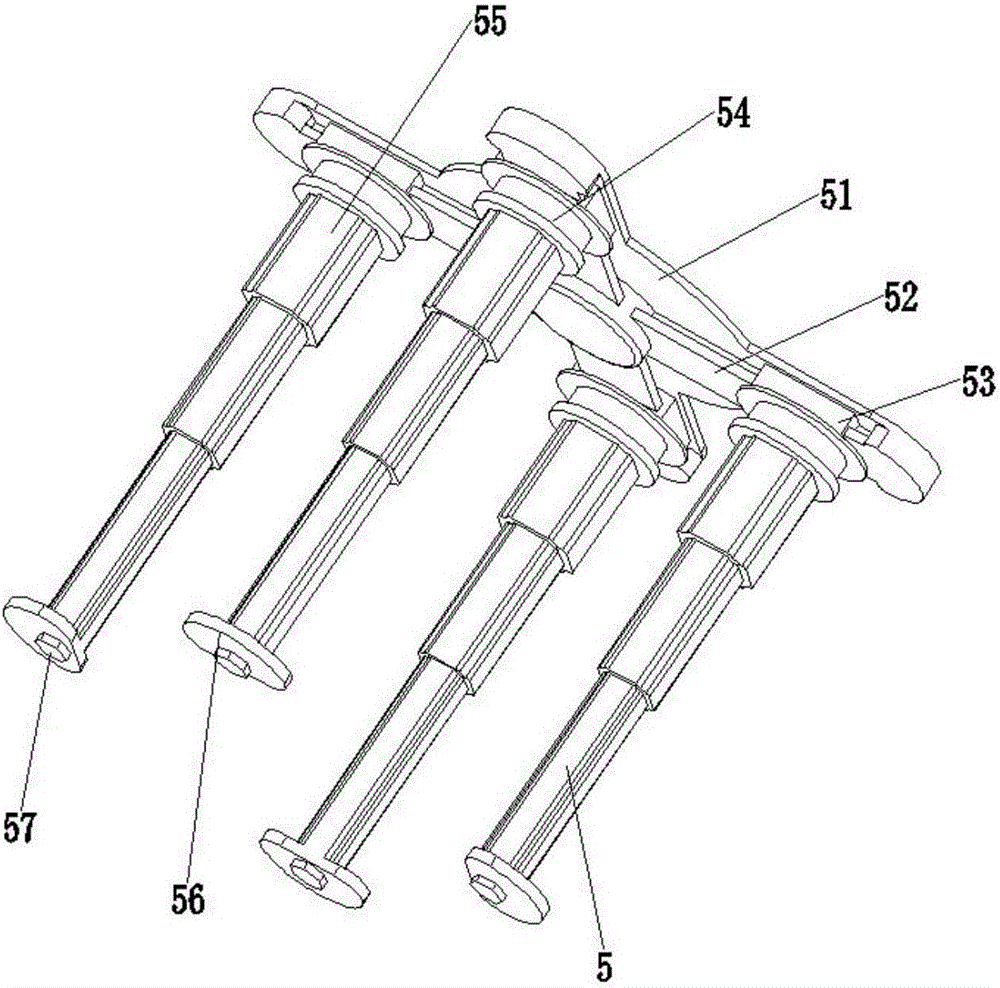

[0018] like Figure 1 to Figure 3 As shown, a mechanical claw for intelligent handling of electric vehicle parts includes a three-degree-of-freedom parallel mechanism 4 and a palletizing manipulator 5; the three-degree-of-freedom parallel mechanism 4 is located directly above the palletizing manipulator 5, and the three-degree-of-freedom parallel mechanism The 4 lower end is connected with the stacking manipulator 5.

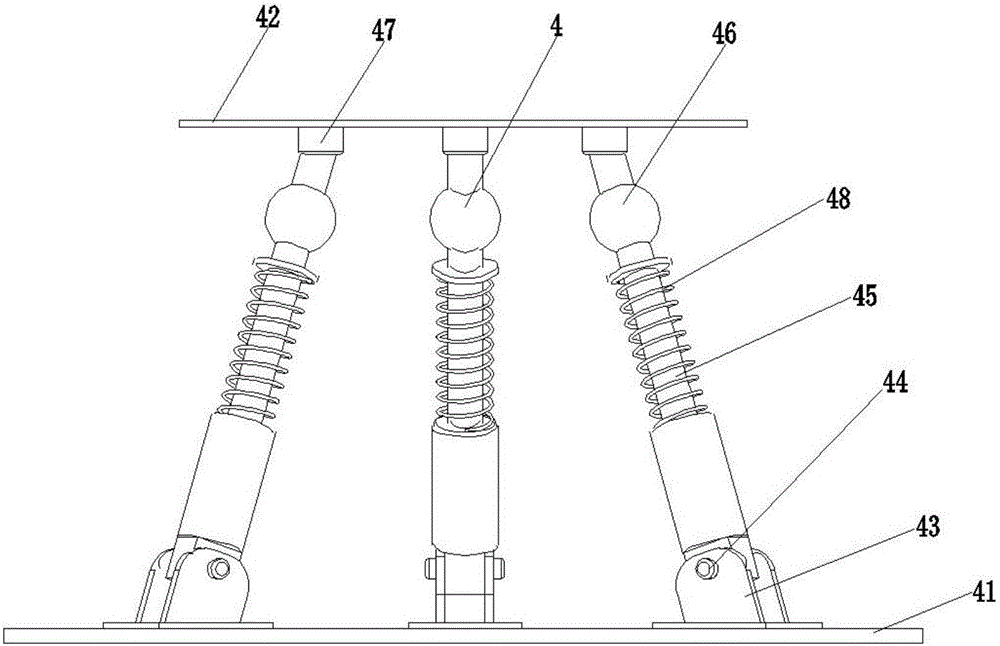

[0019] like figure 1 and figure 2 As shown, the three-degree-of-freedom parallel mechanism 4 includes a fixed platform 41, a moving platform 42, an ear seat 43, a rotating shaft 44, an electric push rod 45, a ball hinge 46, a connecting seat 47 and a limit spring 48, and the ear seat 43 , rotating shaft 44, electric push rod 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com