Trunk outer plate and punching process thereof

A luggage and process technology, which is applied in the directions of superstructure sub-assembly, transportation and packaging, superstructure, etc., can solve problems such as inability to form, and achieve the effect of ensuring the quality of finished products and being easy to process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

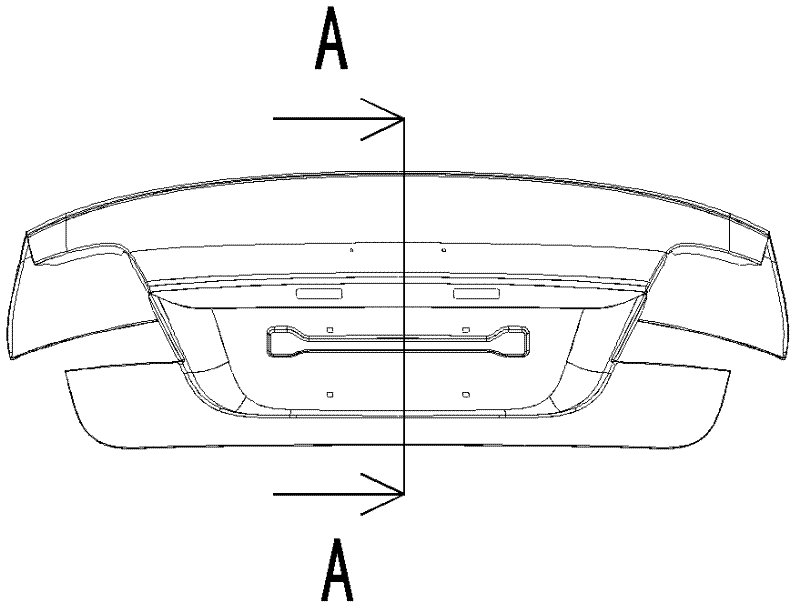

[0035] Such as figure 1 As shown, the trunk outer panel described in the embodiment of the present invention includes a license plate light installation profile, the license plate light installation profile is parallel to the X-axis of the vehicle body, and the trunk outer panel is parallel to The XY plane of the car body is made along the installation profile of the license plate lamp, and the part is divided into two parts. The upper part is above the intersection line, and the lower part is below the intersection line. The upper part includes the license plate lamp installation profile. The upper part and said lower part are joined together by laser brazing.

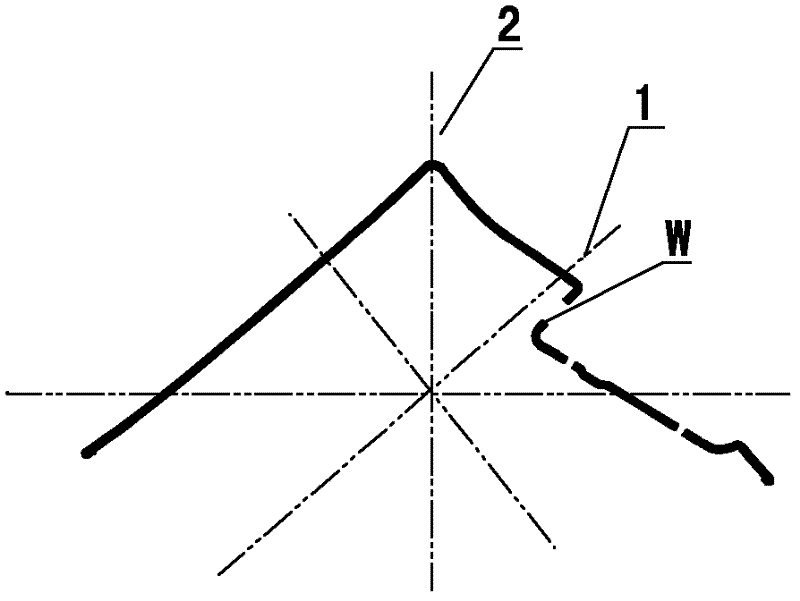

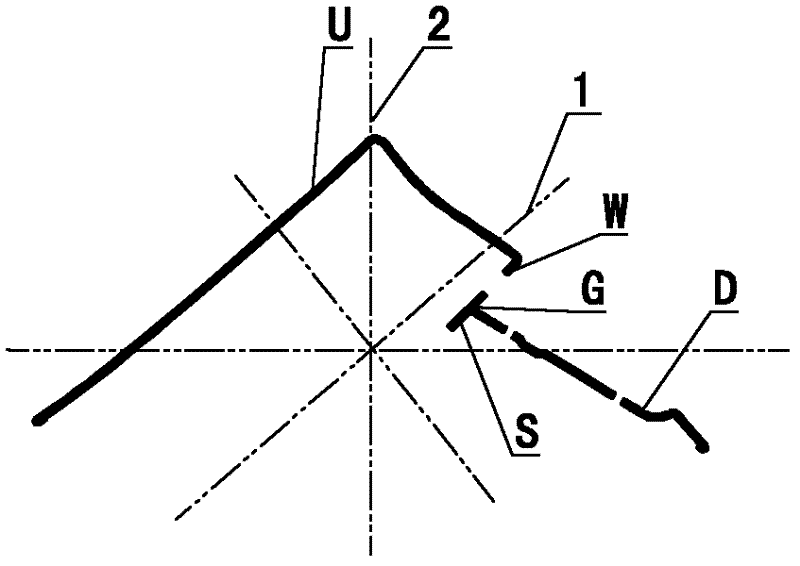

[0036] Specifically, see image 3 As shown, the lower part of the weld formed by the upper and lower parts is provided with a suction rib, and the mounting surface of the license plate lamp is provided with a suction rib. Among them, 1 represents the X-axis direction of the body of the part; 2 represents the stampin...

Embodiment 2

[0038] Embodiment 2 of the present invention provides a stamping process for parts on the outer panel of the trunk, wherein the rear license plate is arranged on the outer panel of the trunk, and the installation profile of the license plate light is parallel to the X-axis of the vehicle body. The trunk outer panel is divided into two parts by making an intersection line parallel to the XY plane of the vehicle body along the license plate light installation surface, and the trunk outer panel is divided into two parts, the upper part is above the intersection line, and the lower part is below the intersection line. The parts on the outer panel of the luggage case and the lower parts are respectively completed by a single stamping process, and connected together by laser brazing to form the outer panel of the luggage case. Among them, the laser brazing is a high-quality, high-precision, low-distortion, and high-efficiency welding method, but it requires high precision of stamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com