Cleaning working chamber and cleanness monitoring system

A monitoring system and studio technology, applied in the field of purification equipment, can solve the problems that the operator does not know the clean condition of the work area and cannot monitor the working condition of the clean studio, etc., and achieves the effect of remote online monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

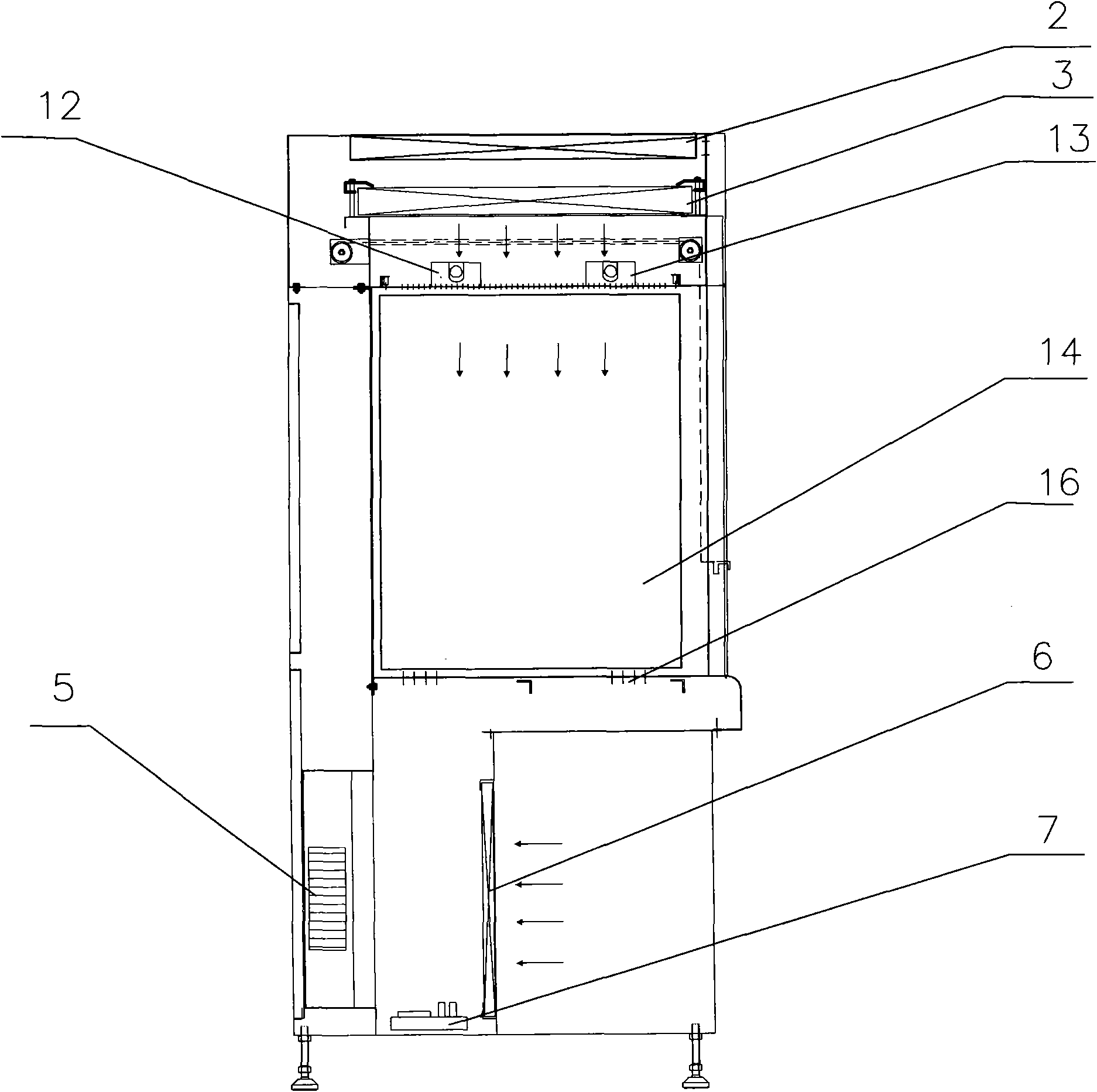

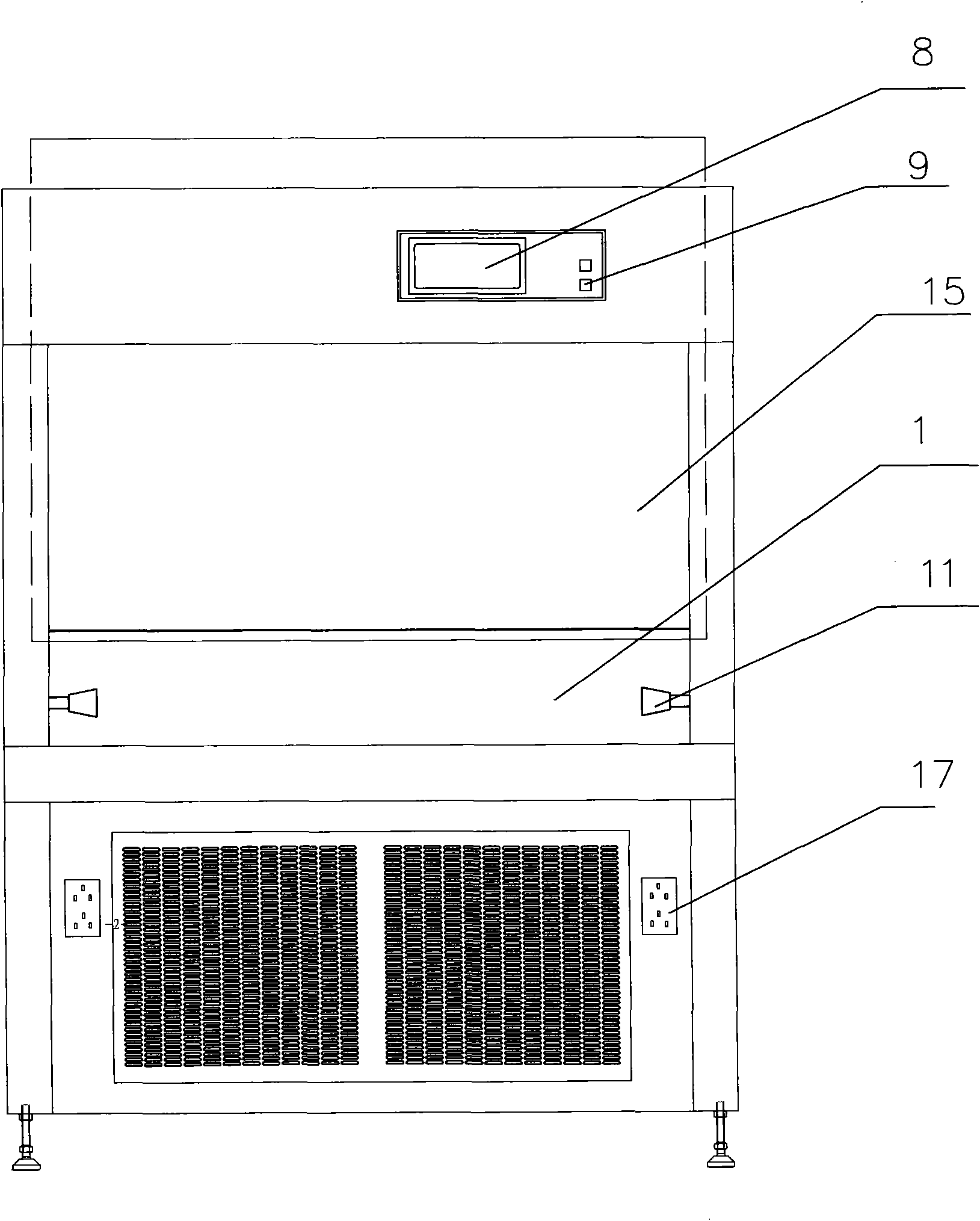

[0022] see figure 1 , figure 2 , a kind of clean working room provided by the present invention comprises upper, middle and lower levels, the middle level is the working area 1, and the top of the upper level is provided with an exhaust air filter 2, and the air supply filter 3 is located above the working area 1, and is connected with the exhaust air The wind filter 2 forms a cavity.

[0023] A laser dust particle transmitter 11 is installed in the working area to detect the size and concentration of dust particles in the working area 1. The installation location can be located on both sides of the working area 1, or above or below the working area. , the number of installations is not limited to one, but can also be two or more. An illuminating lamp 12 and an ultraviolet lamp 13 are also arranged above the working area 1 for illuminating and disinfecting the working area. Toughened glass 14 is arranged on both sides of the working area 1, and a toughened glass sliding do...

Embodiment 2

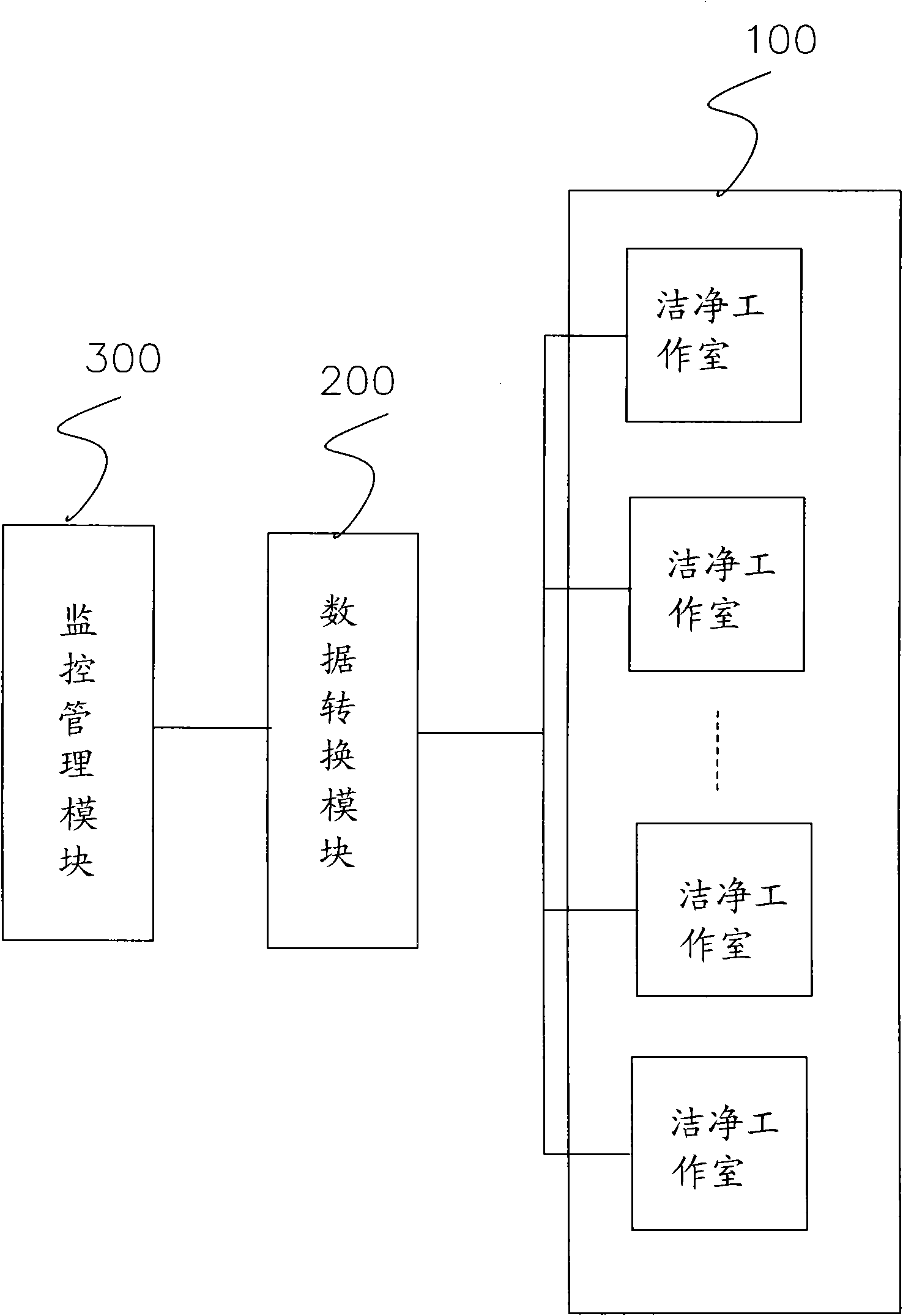

[0029] The present invention also proposes a cleanliness monitoring system, see image 3 As shown in the schematic structural diagram of the system, the system includes one or more clean studios 100 disclosed in the first embodiment, a data conversion module 200 and a monitoring and management module 300 . The monitoring and management module 300 is specifically a computer system, which can transmit the detection results of each clean studio to the computer system for control and management through the data conversion module 200, and can realize online remote monitoring of one or more clean studios.

[0030] In other embodiments of the present invention, a printing module 400 is also included, see Figure 4 , when it is necessary to count the cleanliness test results of some or all working rooms at a certain time or at a certain temperature, the data form can be called out through the computer system and printed through the printing module 400 .

[0031] In the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com