Non-return screw anchor system

A screw anchor and non-return technology, applied in construction, sheet pile wall, infrastructure engineering and other directions, can solve problems such as hidden safety hazards, long construction period, complex piling process, etc. Fast construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

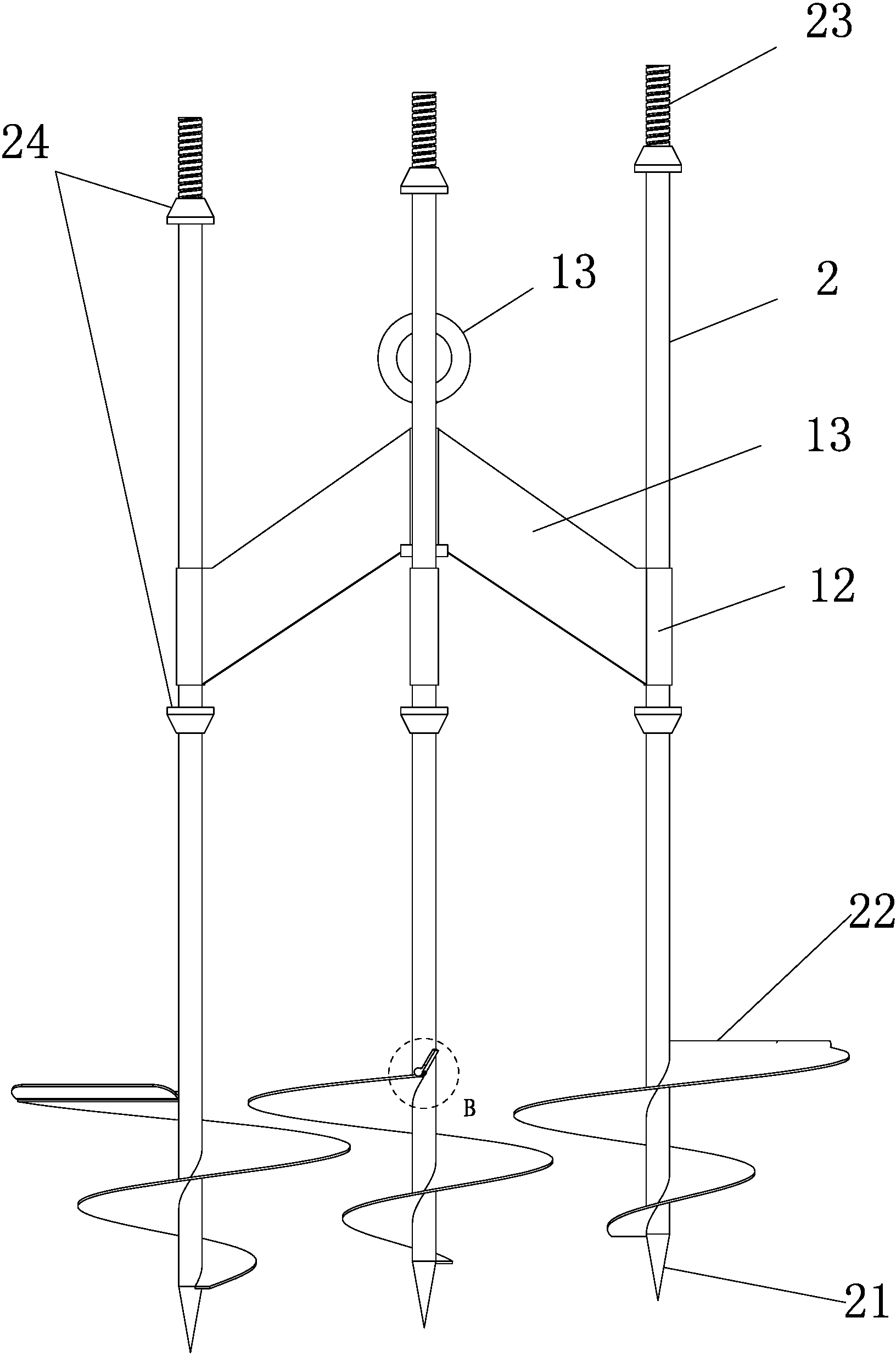

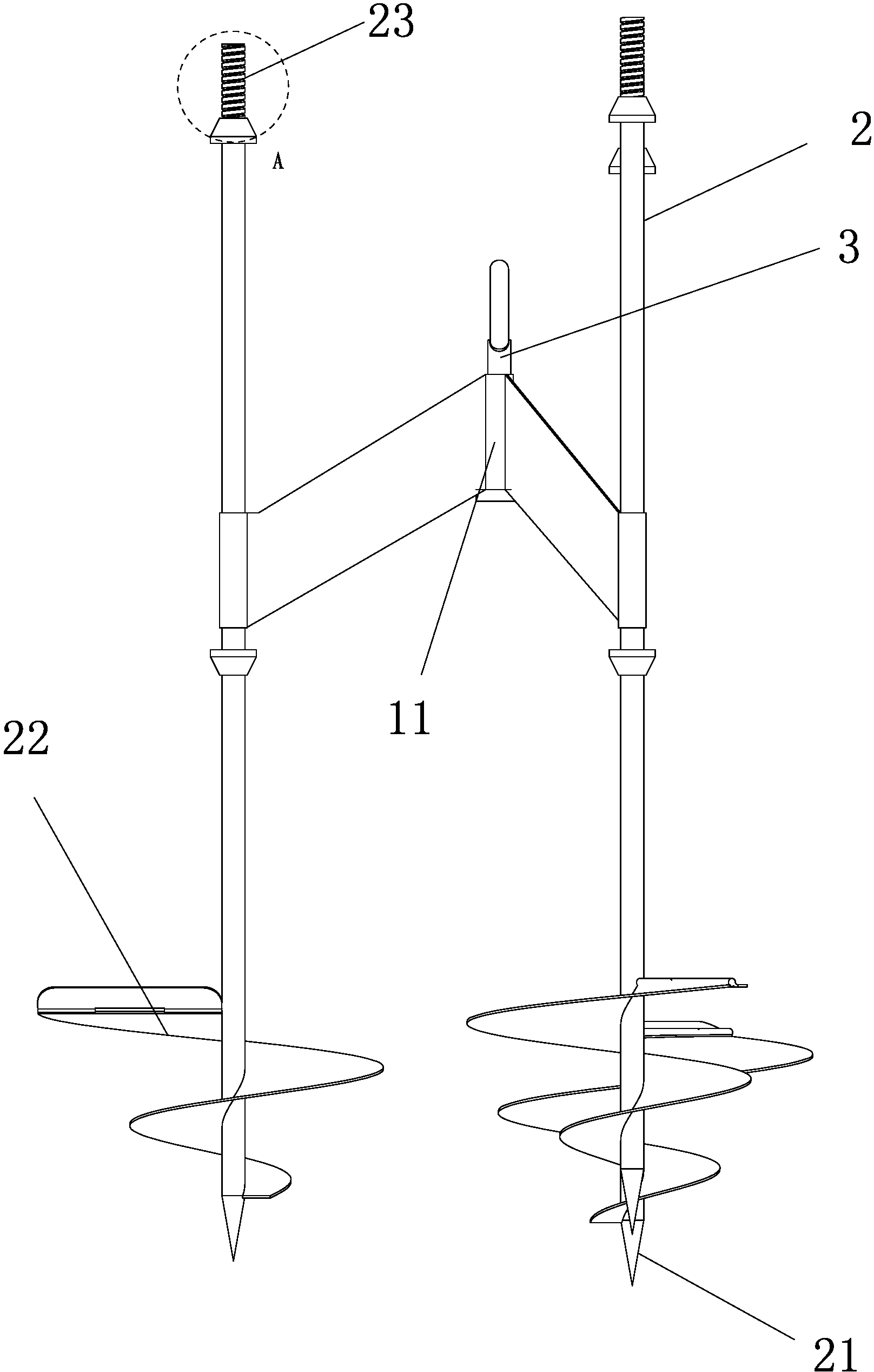

[0030] combine Figure 1 to Figure 9 , the preferred embodiments of the present invention will be described in further detail.

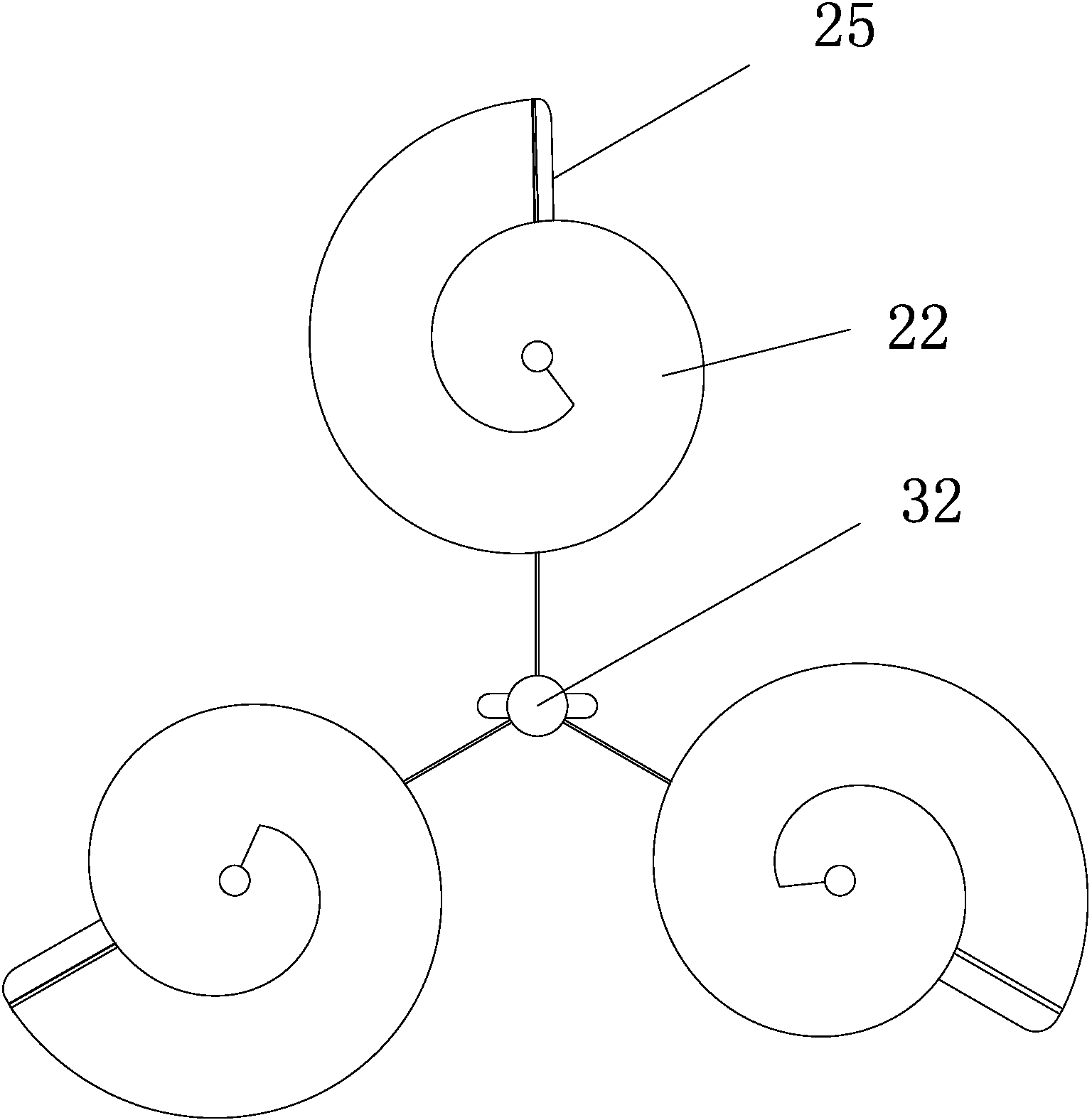

[0031] A non-return helical anchor system, the main components involved include a connector 1 and a non-return helical anchor rod 2, three of which are taken as an example in this embodiment.

[0032] The connecting piece 1 is a component that connects each non-return helical anchor rod 2 , and includes a pull ring rod sleeve 11 , an anchor rod sleeve 12 , and a connecting plate 13 . The ring rod sleeve 11 is in the center, and the three anchor rod sleeves 12 are equiangularly distributed on the periphery, and the ring rod sleeve 11 and the anchor rod sleeve 12 are connected by a connecting plate 13 . In this embodiment, the connecting plate 13 is formed by extending outward from the outer bus bar of the pull ring rod sleeve 11, and then connected with each anchor rod sleeve 12, and the angle between two adjacent connecting plates 13 is 60 degrees. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com