Efficient multi-air outlet energy-saving anti-explosion fan

A multi-outlet, explosion-proof fan technology, used in mechanical equipment, machines/engines, non-variable-capacity pumps, etc., can solve the problems of large fan volume, low static pressure efficiency, and small total outlet area, and achieve small volume. , the effect of high static pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

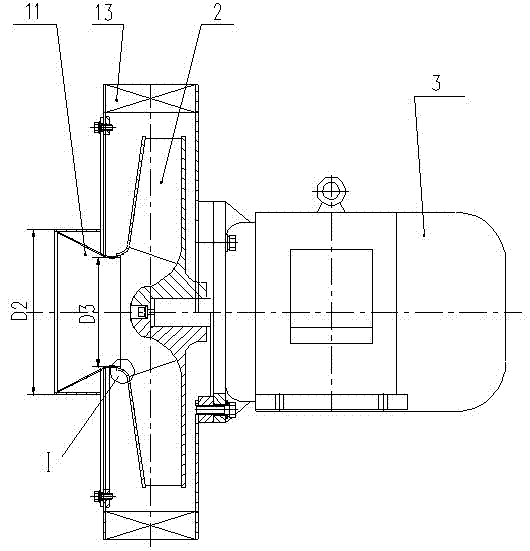

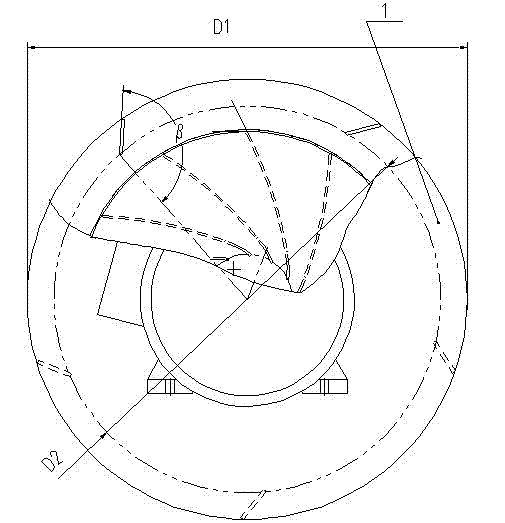

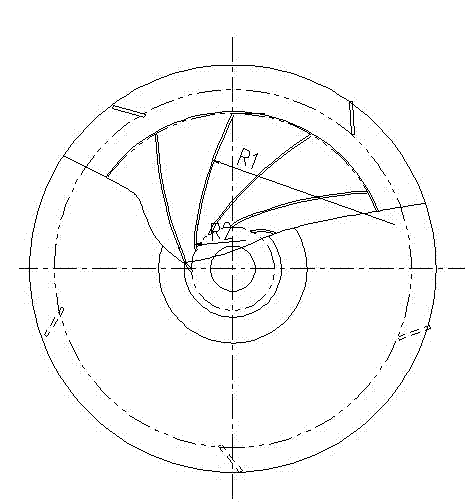

[0027] see Figure 1~4 , figure 1 It is a schematic diagram of the overall structure of the utility model's high-efficiency multi-outlet energy-saving explosion-proof fan. figure 2 for figure 1 right view of . image 3 for figure 1 left view of . Figure 4 for figure 1 Enlarged view of I. Depend on Figure 1~Figure 4 It can be seen that the high-efficiency multi-outlet energy-saving explosion-proof fan of the utility model is mainly composed of a volute 1 , an impeller 2 and a motor 3 .

[0028] see Figure 5~6 , Figure 5 It is a schematic diagram of the volute structure of the utility model's high-efficiency multi-outlet energy-saving explosion-proof fan. Figure 6 for Figure 5 right view of . Depend on Figure 5 and Figure 6 It can be seen that the volute 1 of the utility model's high-efficiency multi-outlet energy-saving explosion-proof fan includes an air inlet 11, a front side plate 12, an air tongue 13, a rear side plate 14 and a reinforcing ring 15,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com