Improved structure for light emitting diode (LED) lamp tube

A technology for LED lamp tubes and improved structures, which can be applied to lampshades, parts of lighting devices, semiconductor devices of light-emitting elements, etc., and can solve problems such as black areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific embodiments.

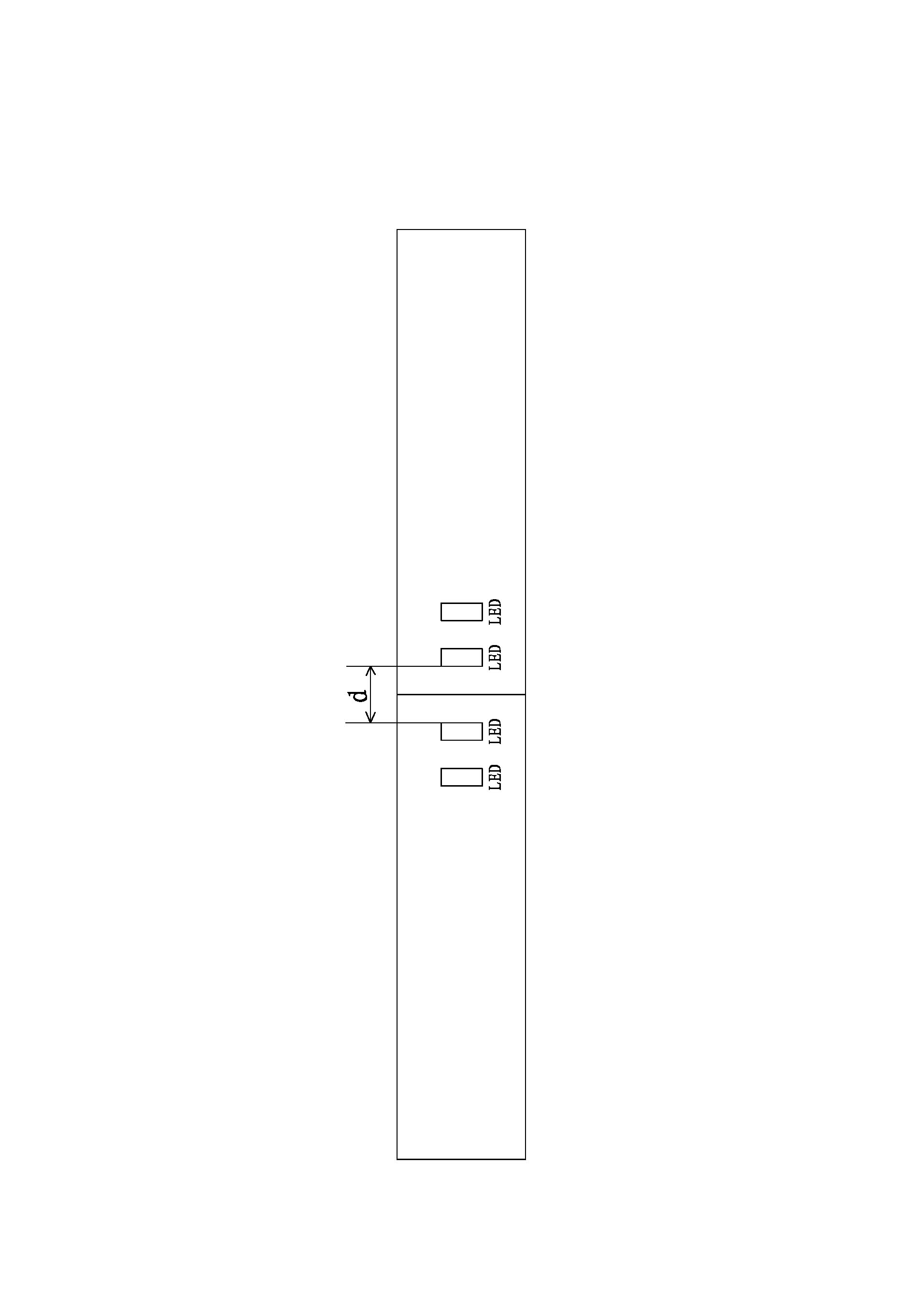

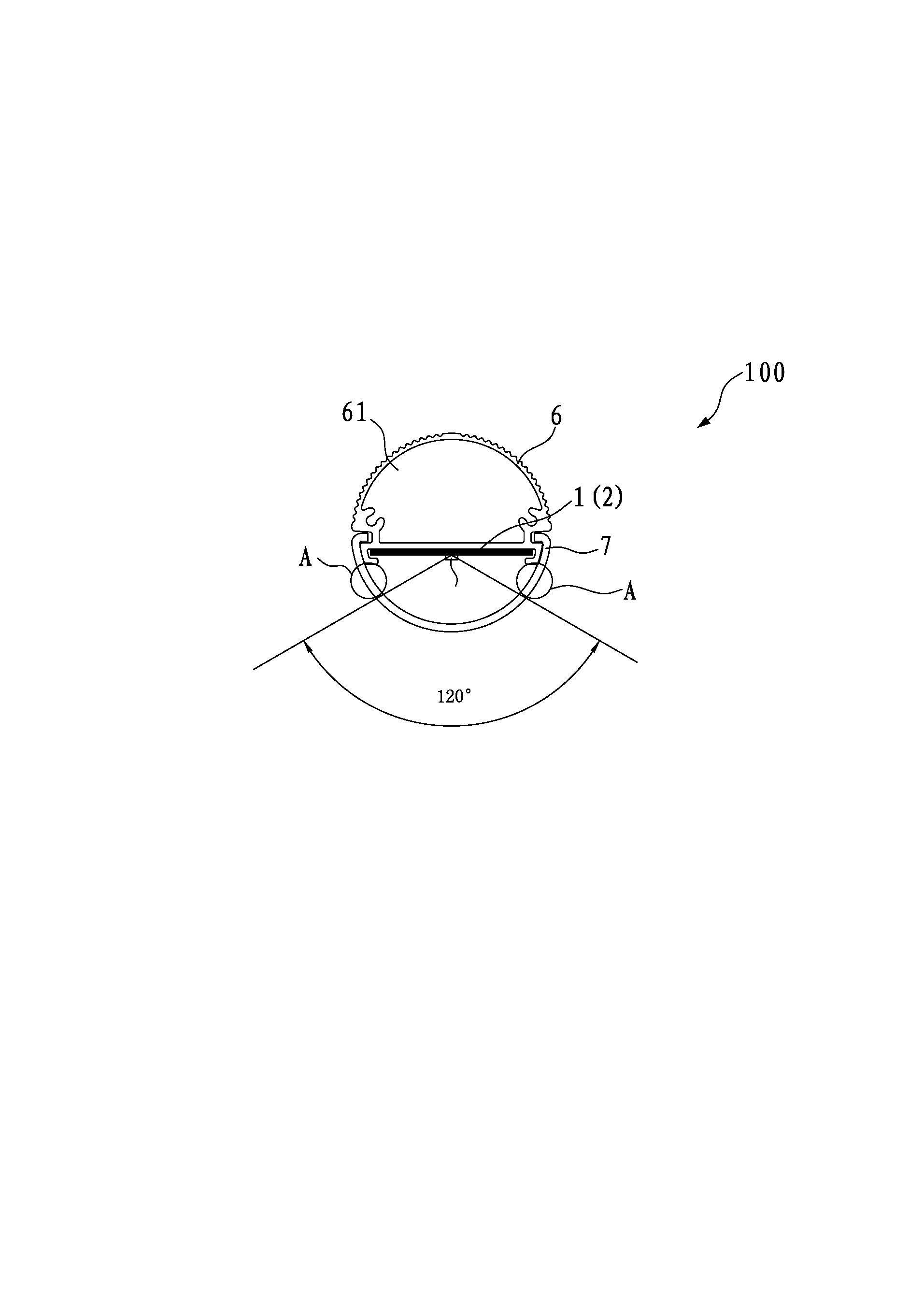

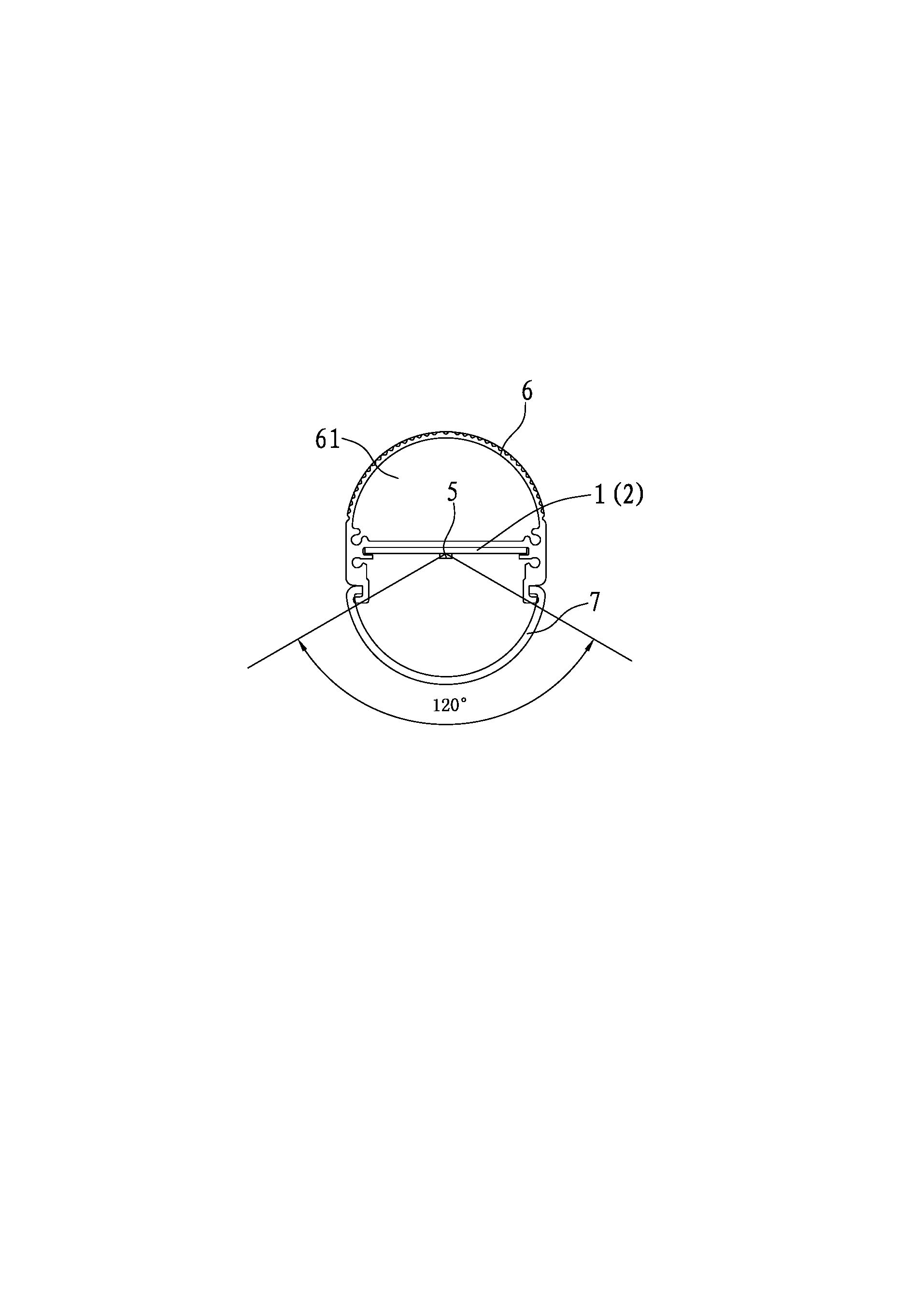

[0035] Please compare figure 2 with image 3 As shown, it is a comparison between the prior art and the technical solution of the present application. In the prior art, the LED fluorescent lamp 100 further includes a housing 6 and a PC cover 7. The housing 6 and the PC cover 7 can be buckled with each other and Then a cavity 61 is formed, and the circuit board is accommodated in the cavity 61. Specifically, in this embodiment, the circuit board is composed of a first substrate 1 and a second substrate 2, that is, the first substrate 1 and the second substrate 2 are contained in the cavity 61; because the existing LED fluorescent lamp 100 diverges light at 120 degrees, but the PC cover 7 does cover half of the entire housing 6, that is, covers an angle of 180 degrees, which will be separated on both sides Form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com