Thermal neutron detector and manufacturing method thereof

A thermal neutron and detector technology, applied in the field of thermal neutron detectors, can solve problems such as the inability to realize the preparation of micro-channel plates, the influence of the preparation process of micro-channel plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

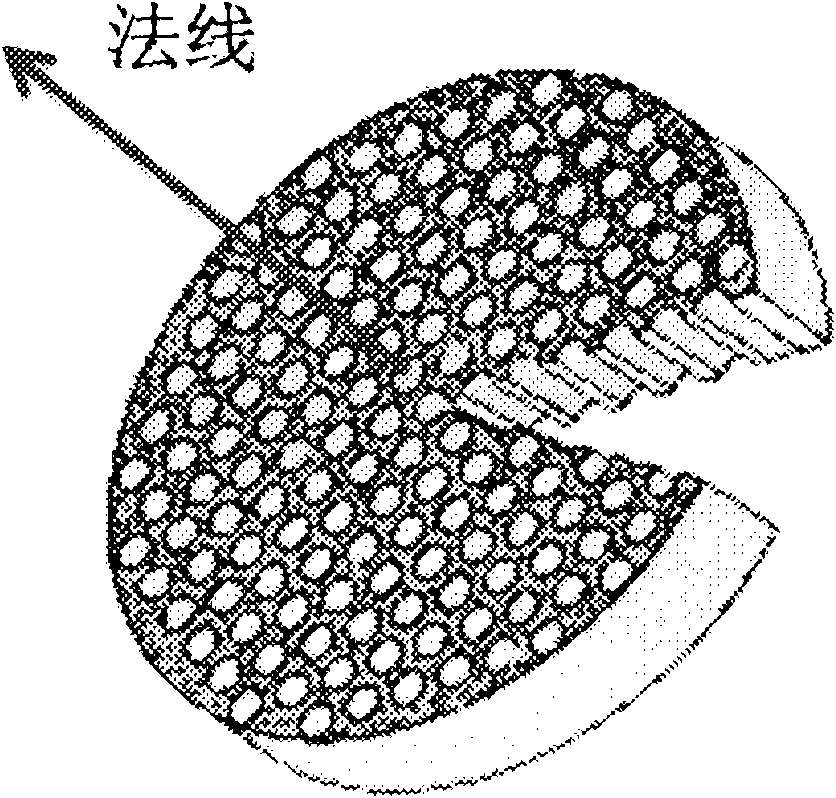

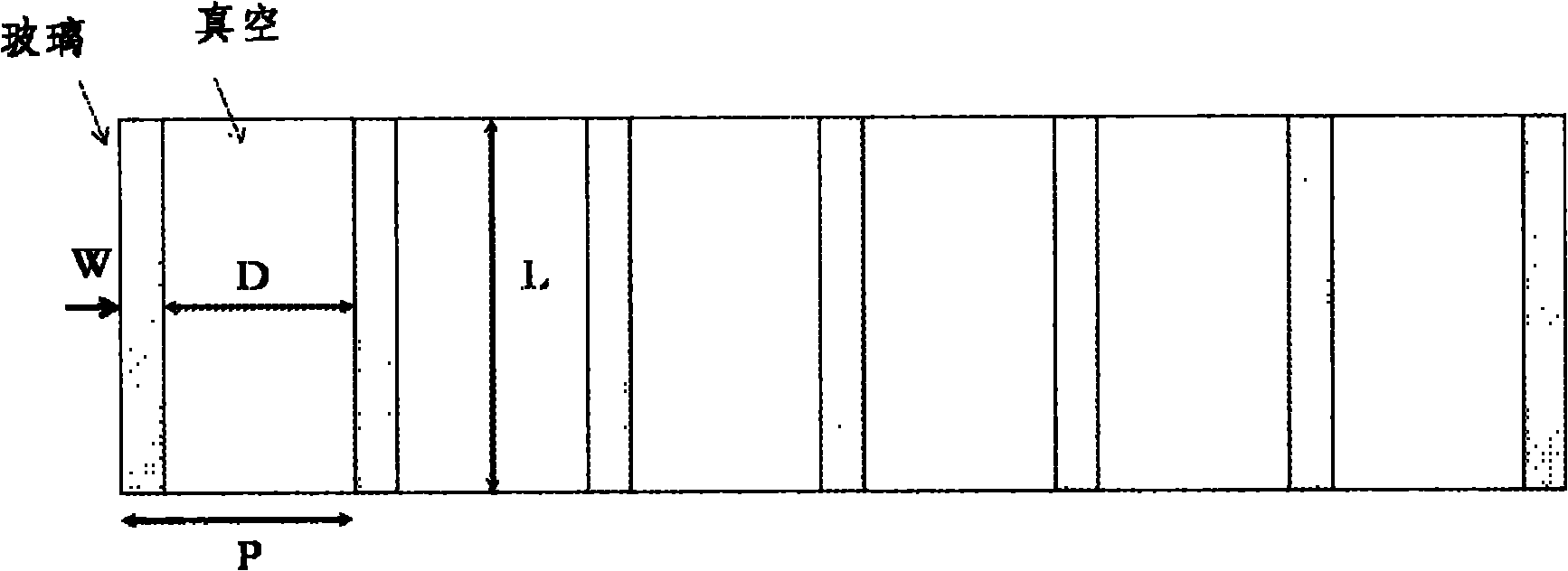

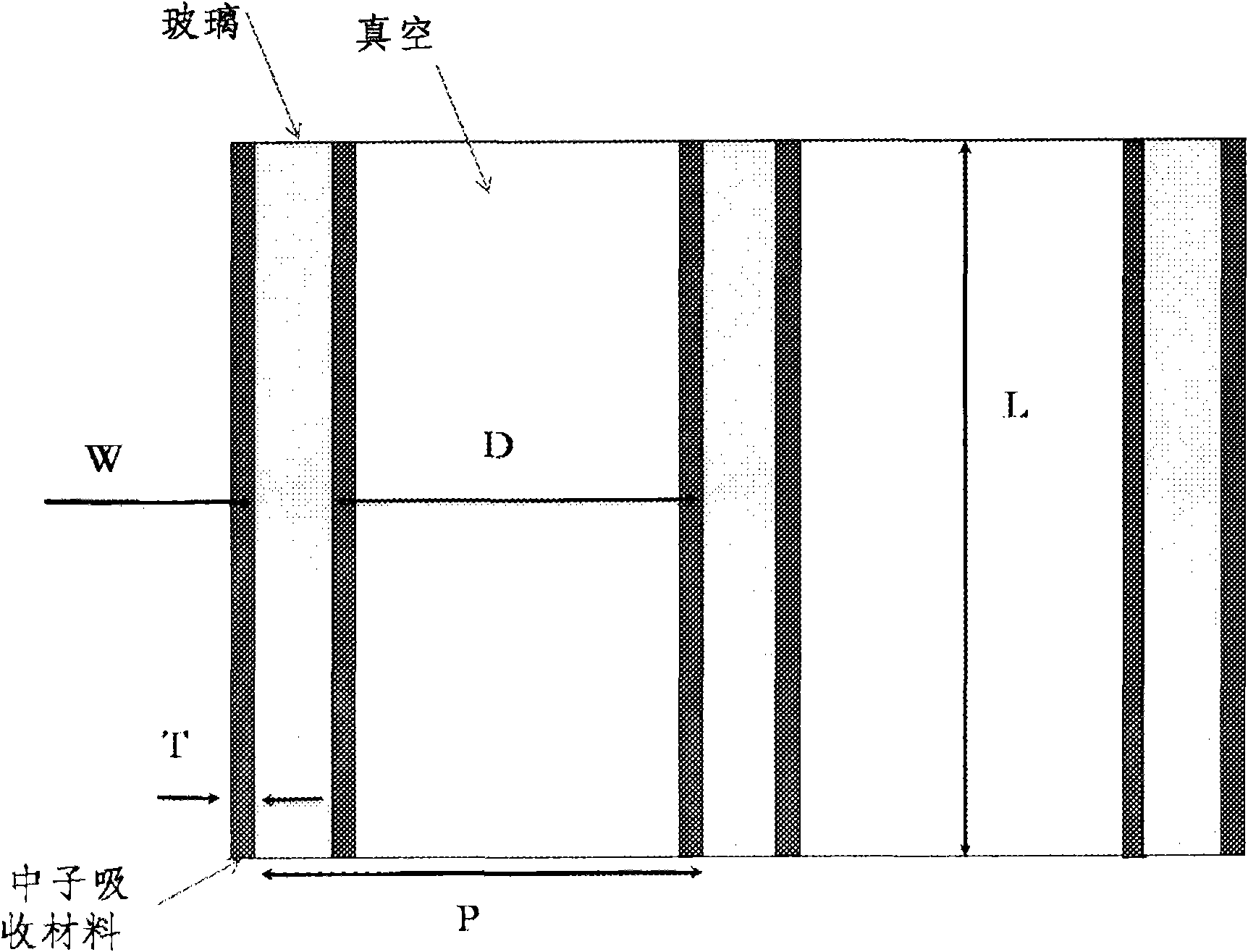

[0016] figure 1 A typical structure of an existing microchannel plate is shown. As shown in the figure, it can be seen that the microchannel plate is a sheet of glass composed of a large number of glass tubes. figure 2 then shows that the sheet glass along the figure 1 The cross-sectional structure in the normal direction shown in . from figure 2 It can be seen that the microchannel plate is composed of a large number of identical aperture structures. The diameter of each aperture is D, generally around 10 μm, and the inside of the aperture is a vacuum. There is glass between the apertures, and the thickness of the glass is W, generally several μm. The diameter D of the aperture plus the thickness W of the glass between the apertures is the dimension P occupied by each aperture. The length of the aperture along the normal direction is L, which is generally several hundred μm to several mm. The specific size of all the above parameters can be determined by the user, or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com