Single-phase ultra-high-capacity nuclear power station transformer

A transformer and single-phase technology, applied in the field of single-phase super-capacity generator transformers, can solve problems such as unreported operation technology, and achieve the effects of increasing lead wire layout space, good shielding effect and reducing loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings.

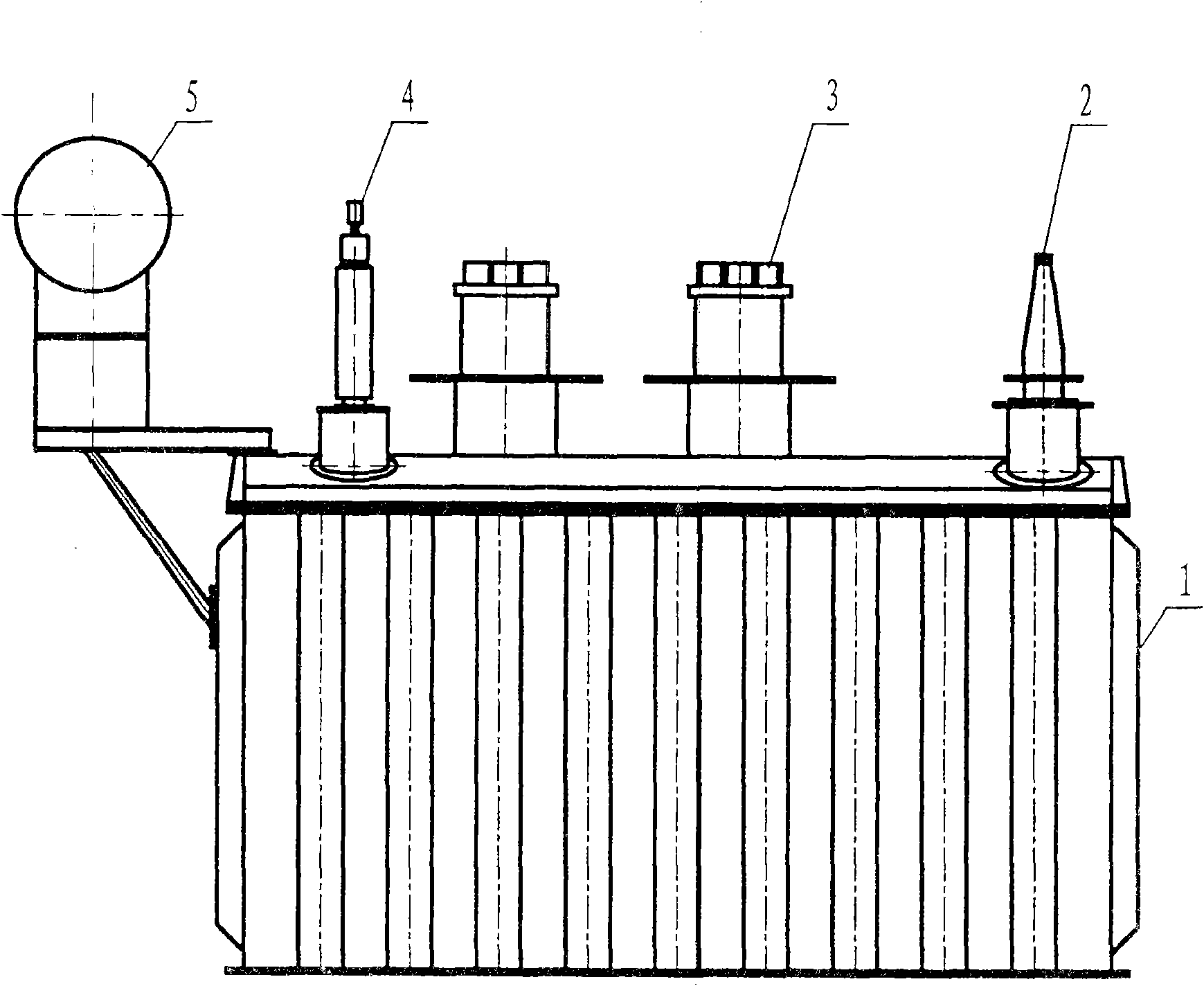

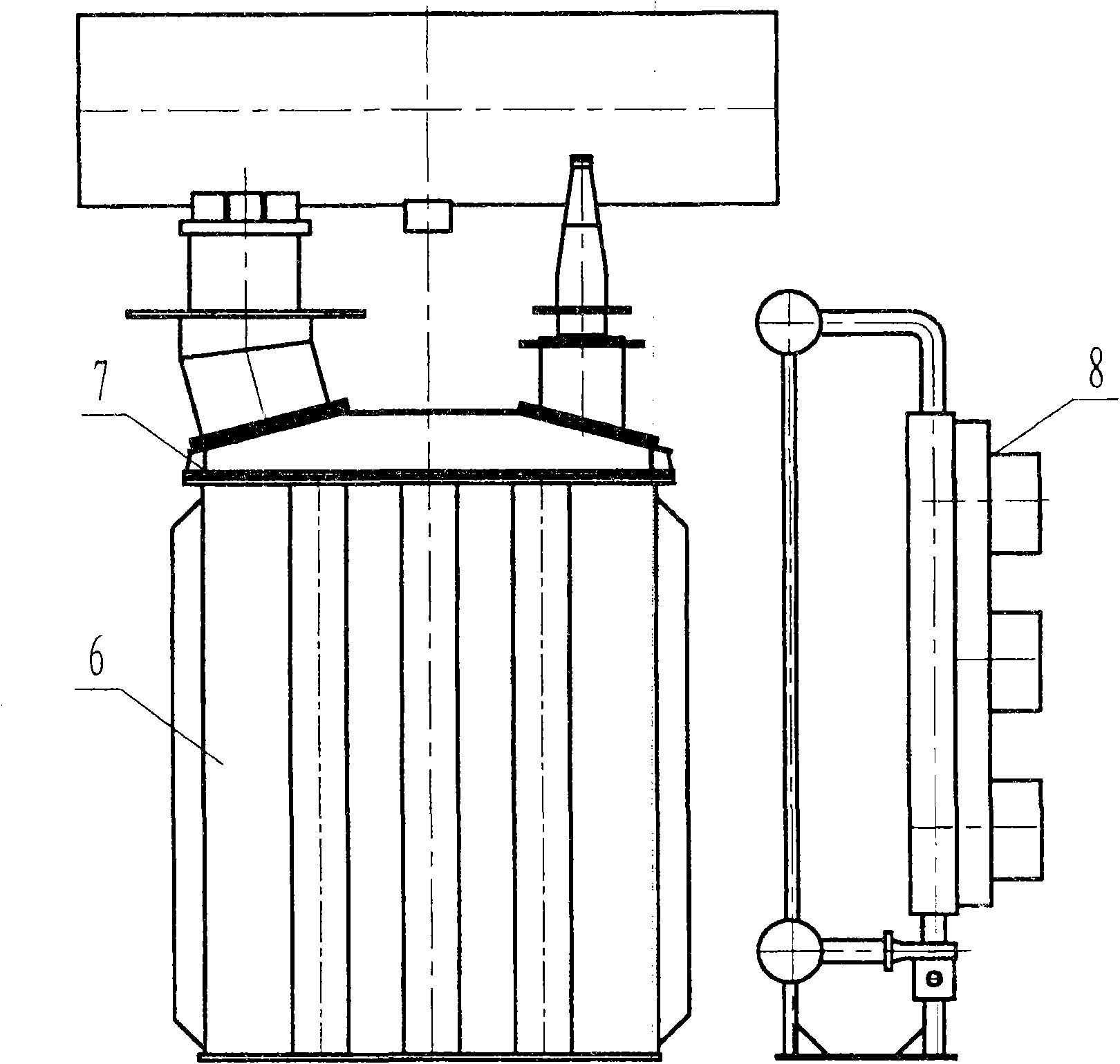

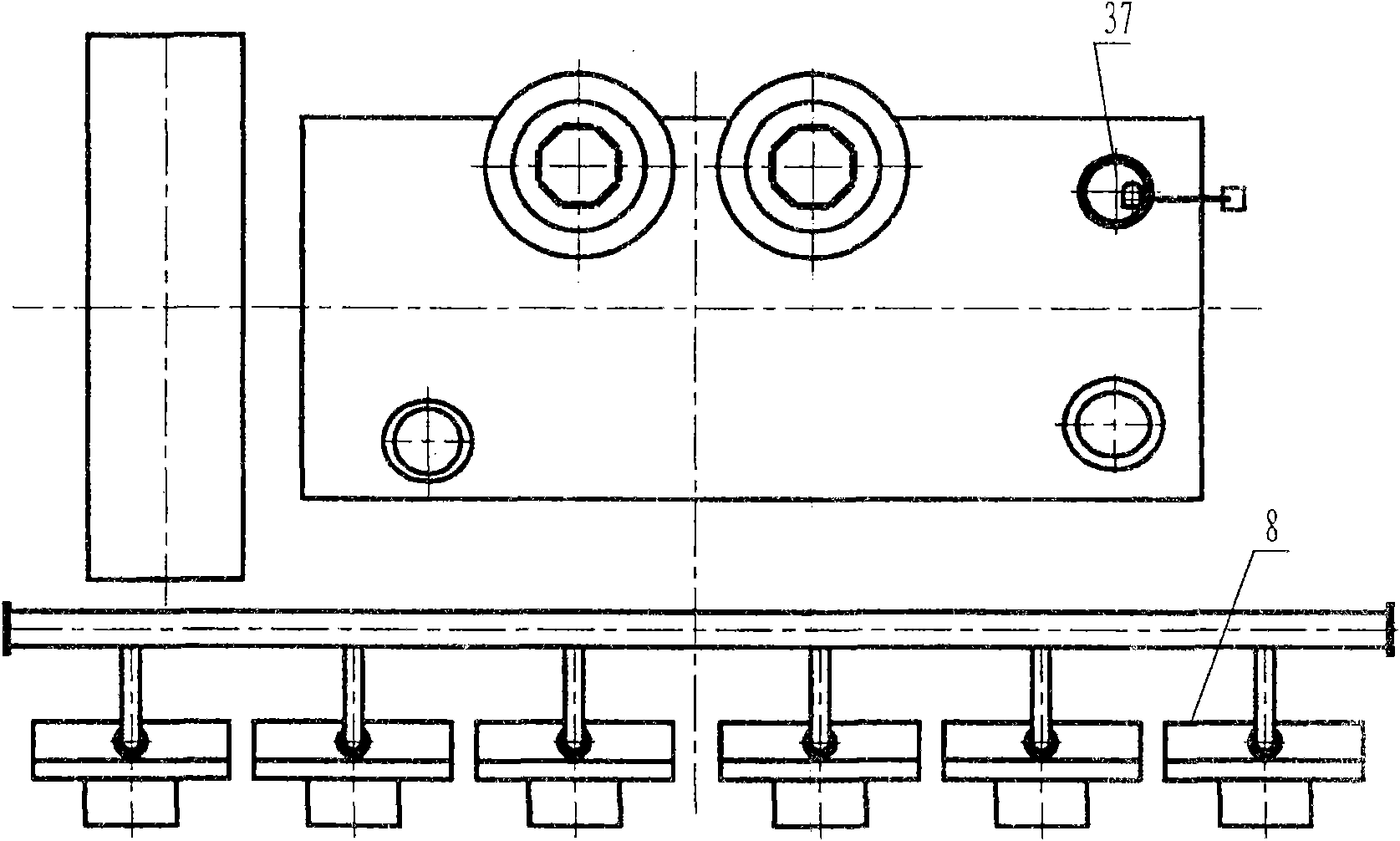

[0047]The ultra-large capacity generator transformer of the present invention takes a single-phase 700MVA / 500kV generator transformer as an example, which has a high-voltage bushing, a low-voltage bushing, a high-voltage neutral point bushing, an oil storage tank, an upper fuel-saving tank, a lower fuel-saving tank, a cooling device and No-load switch, wherein: the upper fuel tank 7 and the lower fuel tank 6 are provided with a single-phase four-column iron core structure, and the two main-column cores of the single-phase four-column core 14 are respectively covered with high and low voltage windings, and the two high and low voltage windings are connected in parallel The two-column low-voltage windings are all at the upper end, and are connected by copper bars 35 to form a low-voltage double-column parallel structure; the high-voltage bushing 2 is directly dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com