Conveying system for integrated circuit chip loader framework

An integrated circuit and conveying system technology, applied in the field of fully automatic conveying system, can solve problems such as low production efficiency, pollution, and lack of precise control parts in the conveying mechanism, and achieve the effect of high degree of automation and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

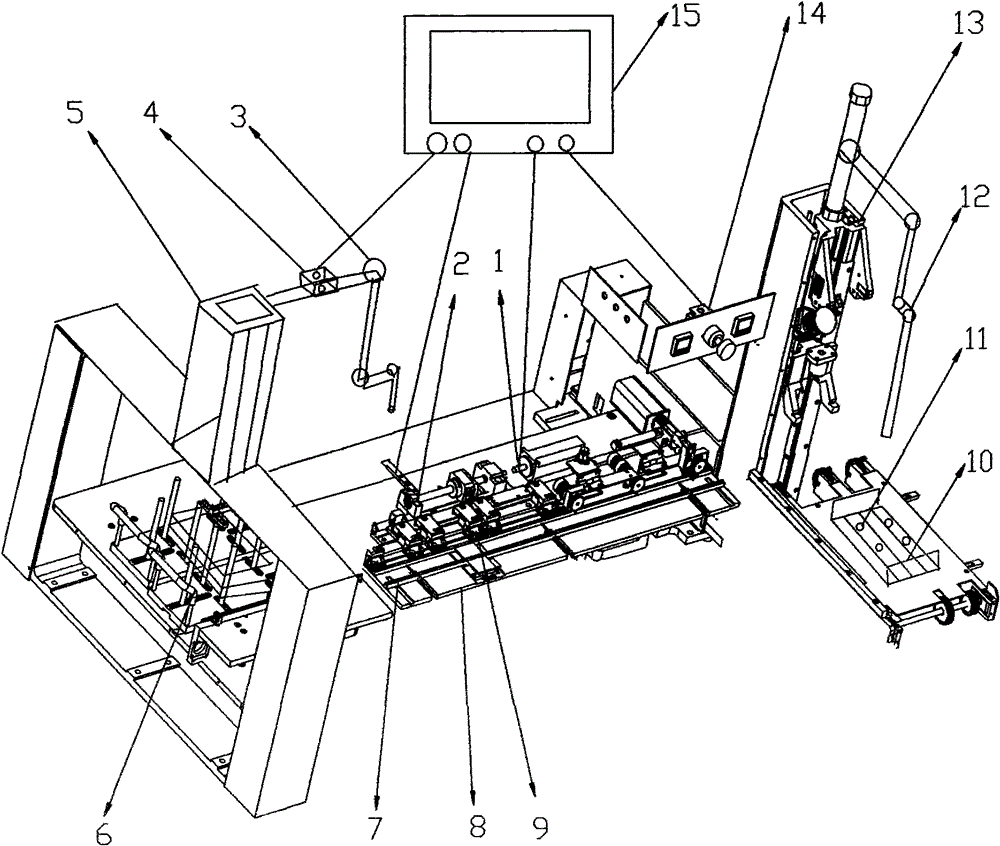

[0014] Select the feeding manipulator 3 and the feeding sensor 4 with suitable specifications and functions to make the feeding mechanism 5; select several sets of clamping jaw groups 9, two rails 7, driving elements 1, and track sensors 2 with suitable specifications and functions to make It is the rail mechanism 8; the blanking manipulator 12 and the blanking sensor 14 with appropriate specifications and functions are selected to be made as the blanking mechanism 13;

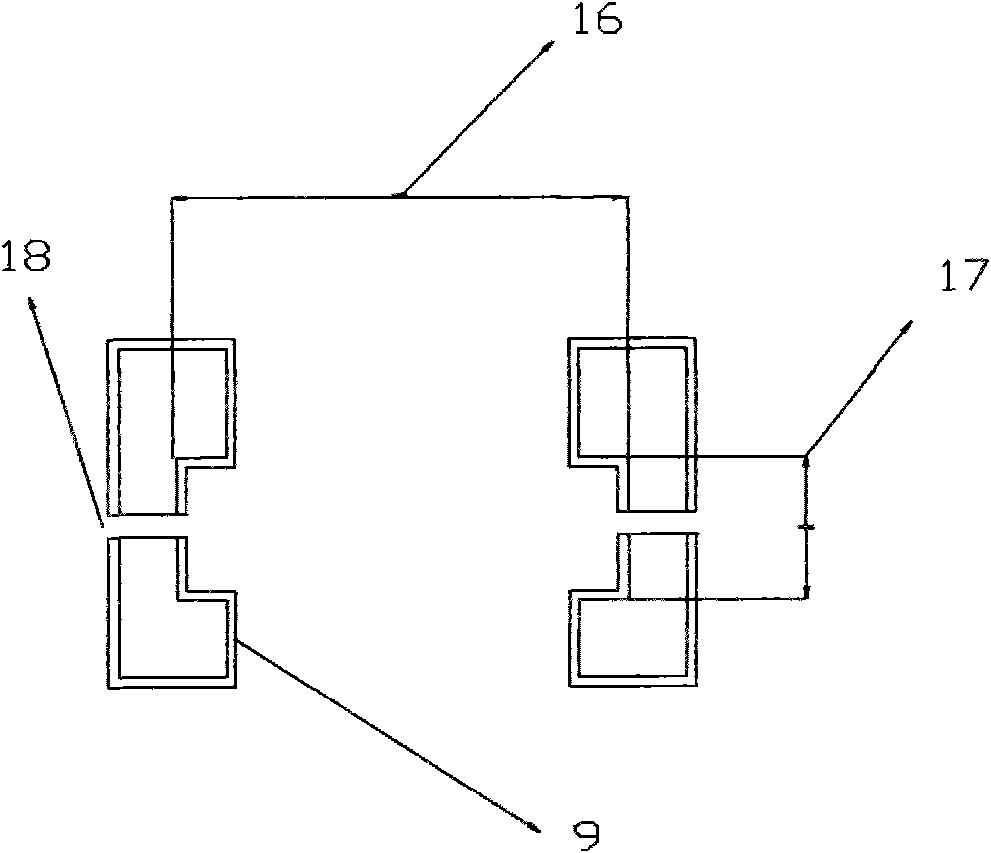

[0015] Arrange each component according to figure 1 Install as shown. The lead frame 11 is now transported into the blanking unit 10, the width 16 between the jaw groups and the thickness 17 between the jaw groups match the dimensions of the lead frame 11, and the width 16 between the jaw groups passes between the jaw groups. The distance between the jaw groups is adjusted, and the thickness 17 between the jaw groups is adjusted through the thickness adjustment slits 18 of the jaw groups.

[0016] After the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com