A device and method for adjusting the size of the top mold system hanger

A hanger and system technology, which is applied to the scaffolding of house structure support, house structure support, house structure support, etc., can solve the problems of less turnover times of hangers, inability to change freely, and high difficulty, so as to achieve a good working environment and save engineering The effect of increasing time and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better understand the technical solution of the present invention, the present invention will be further described below through examples and accompanying drawings.

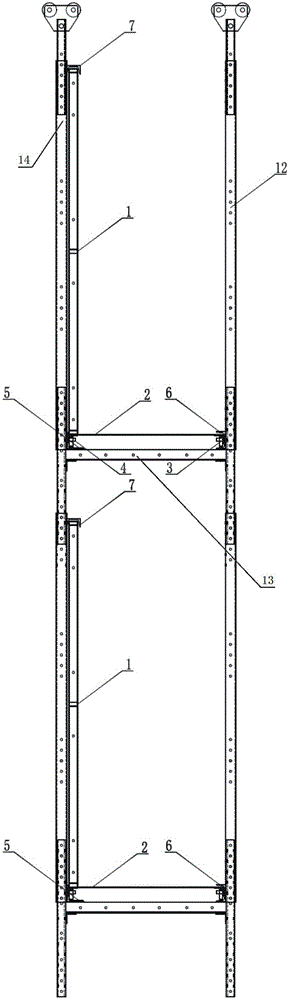

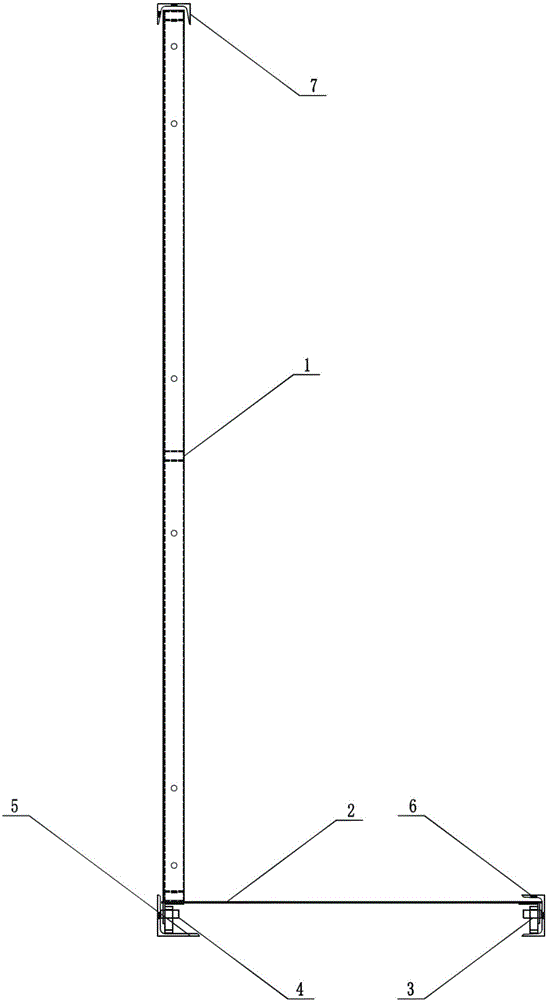

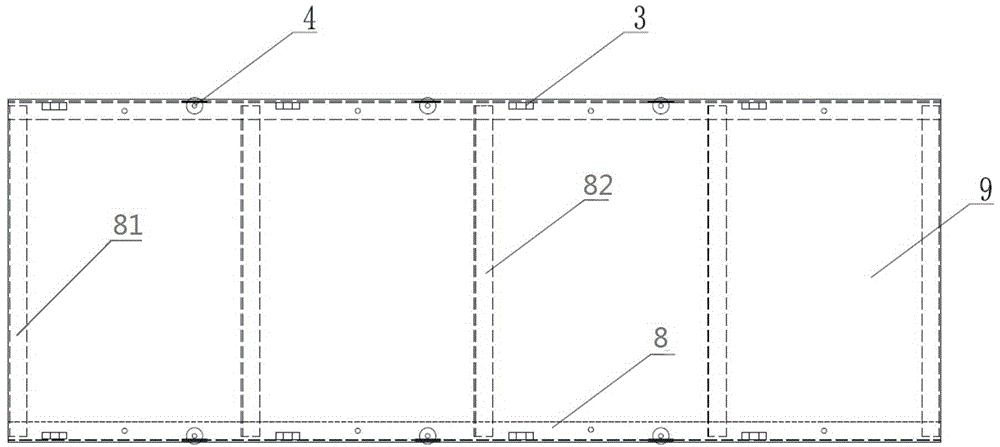

[0033] A device for adjusting the size of the top mold system hanger, such as figure 1 and figure 2 As shown, it includes a facade protective net frame 1, a moving plate 2, a guide angle steel 5, a first guide channel steel 6 and a second guide channel steel 7; Vertical fixed connection, the left and right ends of the lower surface of the moving plate 2 are provided with a plurality of vertical bearings 3 and horizontal bearings 4, and the plurality of vertical bearings 3 and horizontal bearings 4 are arranged along the length direction of the moving plate 2; Angle steel 5 and the first guide channel steel 6 are respectively fixed on the left and right ends of the base plate 13 of hanger 12, and the opening of guide angle steel 5 is upwards, and the opening of the first guide channel steel 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com